How to Select the Right Gate Cutter for Your Job

April 19, 2022

De-gating a plastic part from its runner may be your final operation before shipping the parts to the customer. Often it is a challenge to remove a runner and leave the part cosmetically, functionally and structurally intact. Choosing the proper gate cutter with the necessary physical characteristics and features becomes an important decision.

Therefore, when selecting a gate cutter, consider the length of the handle, blade length and opening, blade angle relative to the handle and the contour of the back of the blade (the blade characteristics should match the part at the area of the de-gating) and features such as a blade stop, type of spring and handles. Consider the following features:

Blade Stop

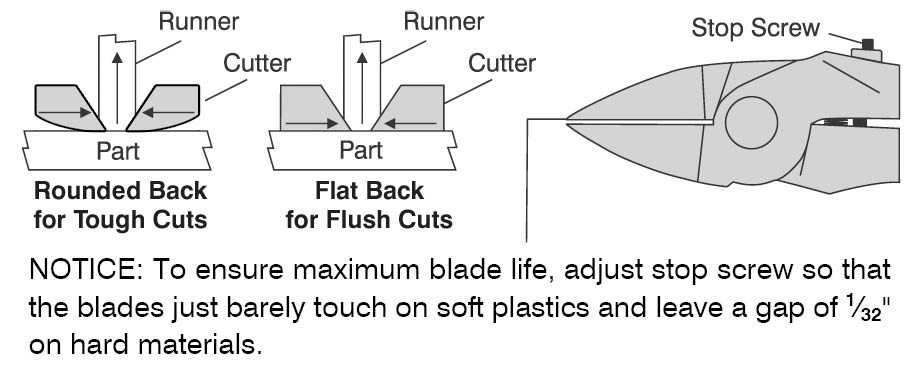

Gate cutters are actually wedges that cut from both sides until the tensile strength of the uncut section at the middle is overcome, and the remainder of the runner or sprue is “snapped” out. This rapid release causes blades to hit each other, shortening their life.

For this reason, a blade stop screw is recommended if the cutter is to be used on hard, brittle materials. The screw should be set so the blades stop short of hitting each other. For softer materials, a better cut can be obtained using a very thin, sharp blade. If a blade stop is used with softer materials (polyethylene, flexible PVC, etc.), it should be adjusted for minimal blade gap. This allows the blades to cut farther through the runner, yet only allows the blades to touch slightly.

Springs

Leaf springs are welded to the handles and covered by hand grips. Generally, they are set to a lower pressure and require less effort to squeeze, thereby reducing user fatigue. Coil springs offer a stronger return pressure “fly back” when releasing from a cut, but require more pressure to make a cut. Also, they can be easily and inexpensively replaced by the operator.

Handles

The length of the cutter’s handles determines how much pressure the operator must exert to cut through a gate or sprue. A cutter with a handle that is too short will cause excessive strain on the operator’s hand. A cutter with a handle that is too large for the operator’s hand is difficult to grip.

Try to match the cutter with the operator’s hand and the gate or sprue being cut. Ergonomic-contoured handles are effective in reducing the fatigue that can accompany the prolonged squeezing action of gate cutting. They minimize strain on the smaller, weaker fingers by keeping them from pulling from a tight-fisted position. This reduces the risk of carpal tunnel syndrome.

We have a wide range of gate cutters to fit all your gate cutting needs. If we don’t have it in stock, chances are, we can make it!

We encourage you to send us a small quantity of parts with the runners attached, so we can recommend the best cutter for your application or we can design unique cutter blade configurations to your specifications. Reduce muscle fatigue and Carpal Tunnel Syndrome with custom-made ergonomic gate cutters.

Contact the IMS Supply Team today at sales@imscompany.com or call for more details and an RA number. Then send a sketch and some samples of your molded parts with uncut gates to get a prompt quotation.

Leave a comment