IMS Company

A trusted partner for the plastics processing industry, offering a wide range of high-quality, process improving products at competitive prices. We are a diversified distributor specializing in supplies, components, auxiliary machinery, and equipment. With 75 years of industry experience, our stocked warehouse ensures fast, reliable delivery, helping you maintain peak production efficiency. Whether you need innovative products, expert support, or tailored solutions, IMS Company has the expertise and resources to keep your operations running smoothly. Visit us at imscompany.com for more!

For 75 years, one thing has never changed at IMS — our single-minded focus on providing products and services designed to help your shop increase efficiency and ramp up productivity.

Check out IMS on YouTube!

Blogs

July 28, 2025 – Why Keiba Gate Cutters Excel in Precision Cutting

June 3, 2025 – Sizing a Desiccant Dryer for Plastic Injection Molding

May 7, 2025 – Mold Cleaners

January 7, 2025 – Time to Purge

November 4, 2024 – Plant Shutdown

October 22, 2024 – Prepare Your Shop for Winter

September 11, 2024 – New Injection Press Setup

August 26, 2024 – D-limonene

August 14, 2024 – Mold Rust Prevention

July 9, 2024 – Mold Cleaner vs. Mold Release

March 25, 2024 – Part Diverting Systems

March 13, 2024 – Chill Out

February 22, 2024 – Why is Moisture a Problem

February 19, 2024 – What is a Vacuum Loader

February 5, 2024 – Injection Molding Nozzle Tips

January 29, 2024 – Metal Separation

May 30, 2023 – Benefits of Insulation

April 22, 2023 – Sustainability

March 20, 2023 – Dew Point Meter/Monitor

March 2, 2023 – IMS Lime Buster

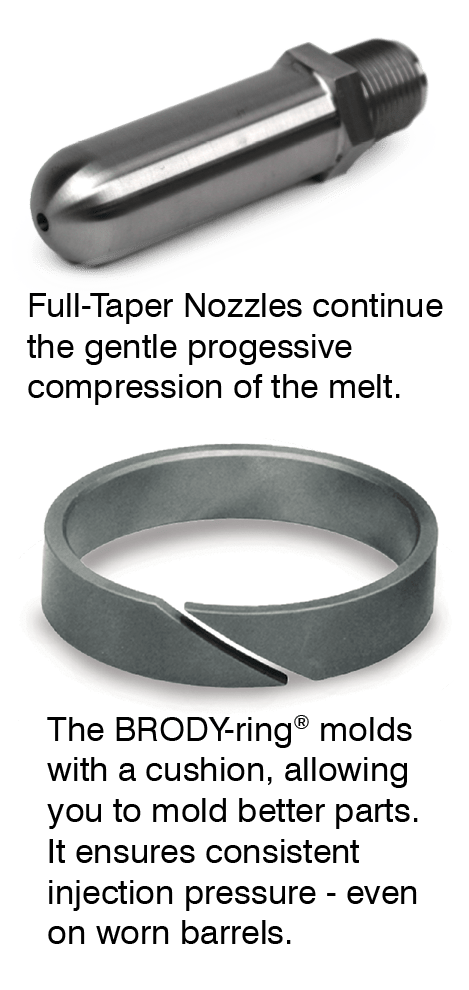

March 1, 2023 – IMS Brody Ring

January 30, 2023 – Clean Room Manufacturing

January 1, 2023 – Heater Band Wiring

December 21, 2022 – IMS Select Drum Tumbler

December 8, 2022 – Plastic Granulators

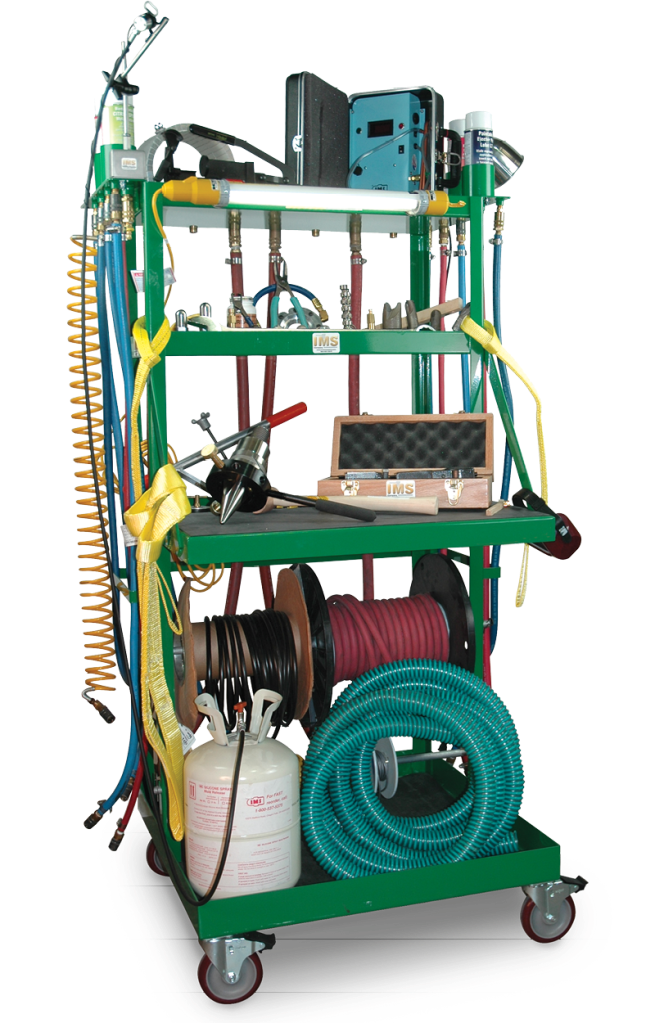

December 6, 2022 – Mold Setup Cart

November 28, 2022 – Eliminate Static and Dust

November 18, 2022 – Extending the Life of Your Heater Band

November 2, 2022 – How to Set Barrel Zone Temps

September 9, 2022 – The Benefits of Extruder Screens

August 24, 2022 – Calculating Heat Load for a Circuit

August 17, 2022 – Purgex Purging Compounds

August 12, 2022 – Air Wipe

August 11, 2022 – IMS Custom Projects

August 4, 2022 – New Shini Hopper Loader Systems

July 21, 2022 – Quick Change Fittings – Thread Profile Sizing

July 19, 2022 – IMS Custom Project

June 20, 2022 – Safety First

June 15, 2022 – IMS Screw Tip Brody Ring

June 15, 2022 – Screw Material Guidelines

June 15, 2022 – Screw Tip Wear Issues

June 15, 2022 – Essential Barrel Information

June 9, 2022 – Mold Safety Checklist

June 2, 2022 – Why Choose High Quality Desiccant?

May 26, 2022 – Circulators 101

May 19, 2022 – Sizing a Chiller

April 25, 2022 – Mold Temperature Control Product Selection

April 19, 2022 – Selecting the Right Gate Cutter For Your Job

April 12, 2022 – Barrel Insulation Blankets

April 4, 2022 – Quick Mold Change

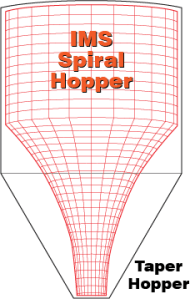

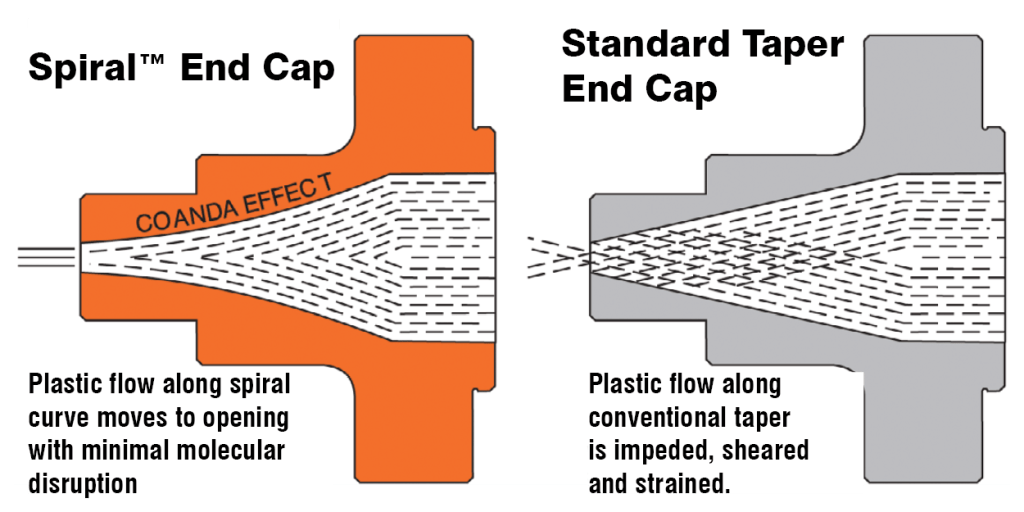

March 14, 2022 – Spiral Technology

February 17, 2022 – Screw Tips

-

Circulators 101

March 6, 2024

Circulators (Thermolators, Temperature Controllers) are essential components in injection molding processes, primarily utilized for controlling the temperature of molds so that as the part cools after injection, it maintains dimension, shape and structure – ensuring consistent quality and efficiency. Controlling the mold temperature is critical to good parts. You can get good melt flow, and the cavity can fill quickly and fully, but if the part is not cooled properly then a good melt flow means nothing.

Circulators need to be compatible with the injection molding machinery and seamlessly integrated into the overall manufacturing setup for efficient operation. Regular maintenance and monitoring of circulators are essential to ensure they continue to function optimally, thereby avoiding downtime and production delays. In advanced setups, circulators may be integrated into the overall automation system of the injection molding process, allowing for real-time monitoring and control of temperature parameters.

Here’s how circulators are typically used in injection molding:

- Cooling: Cools the molds after each cycle. Rapid cooling is essential for improving cycle times and overall productivity.

- Heating: In some cases, circulators may also be used for heating the molds to specific temperatures.

- Thermal Stability: Ensure thermal stability throughout the injection molding process, which is crucial for preventing defects and maintaining part quality.

- Energy Efficiency: Modern circulators often come with energy-saving features to optimize energy consumption during the temperature control process, contributing to cost-effectiveness and sustainability.

- Process Optimization: By precisely controlling the temperature of molds, circulators play a vital role in optimizing the process for different materials and product specifications.

Overall, circulators play a critical role in maintaining temperature control and ensuring the quality, efficiency, and reliability of injection molding operations. Their proper selection, installation, and maintenance are essential considerations for any injection molding facility.

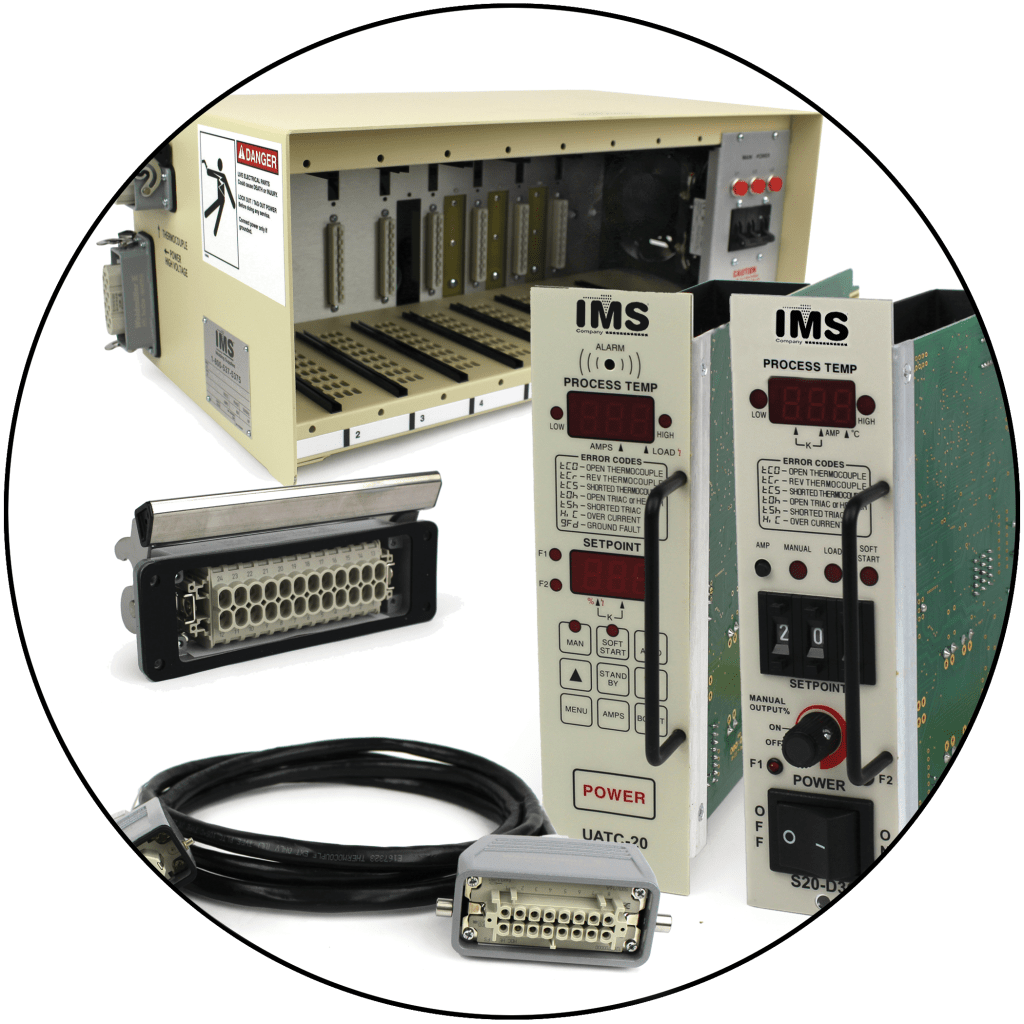

IMS offers several options for temperature control needs: Circulators, Mold Temperature Controllers

You May Also Need:

Heat Transfer Fluids

A Quick Comparison Of Heat Transfer Mediums

• Water — Limited use range: 32° to 212°F. Encourages corrosion.

• Uninhibited Glycols — Allow temperatures to 250°F, but 2½ times more corrosive than water, if not neutralized.

• Automotive antifreeze — Contains corrosion inhibitors, but can foul heat transfer surfaces in less turbulent systems.

• UG-10 Ethylene Glycol — Low silicate formula provides good corrosion protection at a relatively low price.

• EG-17 Ethylene Glycol — Industrial inhibitors coat surfaces and impact pH for maximum corrosion protection.

• Pro-17 Inhibited Propylene Glycol — Non-Toxic Heat Transfer Fluid With Maximum Protection Against Acidity and Corrosion.

• PG-1 Hi-Heat Transfer Fluid — The Ultimate, Non-Toxic Fluid For Non-Pressurized Heating To 600°F.

• FF-1 Oil System Flushing Fluid — Improves heat transfer for faster cycles.

• PSC Plus Oil System Cleaner — Maximizes heat transfer for more parts and increased quality.In addition, how efficiently any of the above units work is directly tied to how clean your mold passages are. Any buildup of scale can affect the transfer of heat. The passages need to be checked and maintained regularly. To help with that, IMS offers the Limebuster which helps remove the scale buildup in mold passages. Just 1/64″ of scale can reduce the heat transfer rate up to 40%. Using an acid/water mixture, the fluid is circulated by a low pressure pump. The fluid helps dissolve the scale slowly so good heat transfer can return. This type of unit also is used to clean heat exchangers.

While the above is basic in its presentation, the message is clear; IMS understands and can help. IMS has the expertise and the equipment to help maintain and even improve your process. Good parts and reduced scrap means you make money.

That is what we are here to help with. Call IMS Today for all your Injection Molding needs.

-

Why Keiba Gate Cutters Excel in Precision Cutting

Perfecting the Balance of Strength and Thickness

IMS Company is your trusted source for a variety of Gate Cutters to fit your needs and we are excited to add to our catalog Keiba Gate Cutters!

A gate is a small opening that connects the runner (where molten plastic flows) to the mold cavity. After the part is molded and ejected, there’s usually a small nub or protrusion of plastic at the gate location. A gate cutter is essential in post-processing of injection molded parts to remove the small leftover plastic at the gate and ensure the finished product is within spec.

What makes Keiba cutters unique?

Recently, IMS staff sat down with Gerard Verdino, former Director of Keiba US, to discuss what makes Keiba Gate Cutters so special. Below is a summary of his 4 Key Points of what makes Keiba Gate Cutters unique.

- Keiba has perfected the balance of strength and thickness. With Keiba’s Thin-Blade Technology, the blades cut the plastic rather than pushing it apart, making for a more perfect cut. This reduces stress on the operator and the finished part. The technology works so well that Keiba has not needed to change their design for the last 25 years.

- Keiba cutters are crafted with a full blade cutting edge that goes all the way to the base of the hinge. “Most cutting is done naturally at the base so it’s really important to not have that gap at the base of the blade.”

- Every single cutter is individually hand-inspected and adjusted before shipping to the customer. Quality Control Inspectors check that the blades align precisely with no gap. Inspectors then test the cutting performance to ensure that every cutter delivers consistent quality out of the package. No adjustment required!

- A subtle, precise blade bevel prevents the hinge from loosening and maintains the blade alignment for the life of the cutter. “Very few manufacturers are aware of this point but it’s very important and very difficult to engineer into every single cutter. The lower hinge has got to come above the upper hinge.”

-

How to Size a Desiccant Dryer for Plastic Injection Molding

What is the material? How many pounds per hour do you want to process?

Properly drying plastic resin is essential to achieving high-quality molded parts, especially for hygroscopic materials such as nylon, PET, or polycarbonate. At IMS Company, we offer Dri-Air desiccant dryers engineered for efficiency, reliability, and precision.

One of the most common questions we hear is: How do I size the right dryer for my process?

1. Know Your Material and Throughput

Before you can select the correct dryer, you must answer two critical questions:

- What material are you drying?

- How many pounds per hour will you be processing?

Each plastic resin has its own recommended drying time and drying temperature. You can usually find these values in your material supplier’s technical datasheet. These specs are the foundation for dryer and hopper selection.

2. Dryer Sizing Rule of Thumb

A general guideline when selecting a dryer is: 1 CFM of process air per pound of material per hour. For example, if you are processing 25 pounds of nylon per hour, you’ll need a dryer capable of delivering 25 CFM of dry air.

3. Hopper Sizing Rule of Thumb

The drying hopper needs to be sized so that the material spends the full recommended drying time in the hopper before reaching the feed throat.

Hopper Size (lbs) = Drying Time (hrs) × Throughput (lbs/hr). Example: If your material requires 3 hours of drying time and you process 25 lbs/hr, then:

- Dryer blower: 25 CFM

- Drying hopper: 75 lbs

This ensures every pellet gets the full 3 hours of exposure to dry air, resulting in fully conditioned material when it reaches your screw.

4. Dryer Configurations

IMS/Dri-Air offers several desiccant dryer configurations to suit your floorplan and process needs:

- Machine-mounted dryers – Best for smaller applications with limited space.

- Floor-mounted dryers – Ideal when space is available and you need a dedicated drying station next to the press or extruder.

- Portable dryers – Designed for flexibility—move them from machine to machine as needed.

Refer to catalog page 686, (or your printed IMS catalog) for hopper sizes, mounting options, and blower capacities.

5. Why IMS/Dri-Air Dryers Save You Money

What makes IMS/Dri-Air dryers different? Efficiency.

Our dryers regenerate the desiccant beds using dry process air, not ambient air. This allows the heaters to operate only when regeneration is necessary—not on a fixed timer. This is controlled by thermocouples embedded in the beds.

Benefits include:

- Shorter heater run-times

- Lower energy consumption

- Faster payback

Other systems use timers or ambient air, which wastes energy and leads to inconsistent results.

Additionally, bed switching is also based on temperature, not time. This approach eliminates dew point spikes and delivers stable drying performance, part after part.

6. Optional High-Temp Cooling

If you’re drying materials at or above 250°F, we recommend an after-hopper cooler. This ensures your material won’t be overheated before entering the machine and protects downstream components.

Final Thoughts

Proper dryer sizing is critical for material performance and processing consistency. IMS/Dri-Air desiccant dryers are engineered with energy savings, consistent drying, and operational flexibility in mind.

If you’re unsure which dryer suits your needs, contact our team—we’ll help size the perfect system for your material, throughput, and floor layout.

-

Mold Cleaners

In Injection Molding

1. Maintain Mold Integrity & Longevity

Residue from polymers, release agents, and contaminants can accumulate on mold surfaces. Mold cleaners help remove these, preventing wear and corrosion. Regular cleaning reduces costly mold repairs or replacements, preserving precision tooling.

2. Ensuring Product Quality

Contaminants on the mold can lead to defects such as blemishes, streaks, or parting line mismatches. A clean mold ensures that the parts produced meet tight tolerances without warping or deformation caused by residue interference.

3. Reducing Downtime

Clean molds reduce the frequency of stoppages caused by defects or ejection issues. Preventive cleaning reduces unplanned maintenance, ensuring continuous production and higher overall equipment effectiveness.

4. Improving Safety and Cleanliness

Using proper cleaners minimizes the release of harmful fumes or dust. Non-cleaned molds can have sharp burrs or sticky surfaces that pose safety risks to workers.

5. Compatibility with Various Materials

Modern mold cleaners are formulated to be compatible with different mold materials (e.g., steel, aluminum) and coatings, which ensures effective cleaning without damaging the mold.

Types of Mold Cleaners

1. Solvent-Based Mold Cleaners

- Use: Dissolves and removes grease, wax, silicones, and resin buildup.

- Example Products: IMS Mold Cleaner Red 2000

- Pros: Quick-drying, effective on tough contaminants.

- Cons: May be flammable or emit strong fumes—proper ventilation needed.

2. Non-Flammable Mold Cleaners

- Use: Ideal for environments where fire hazards are a concern.

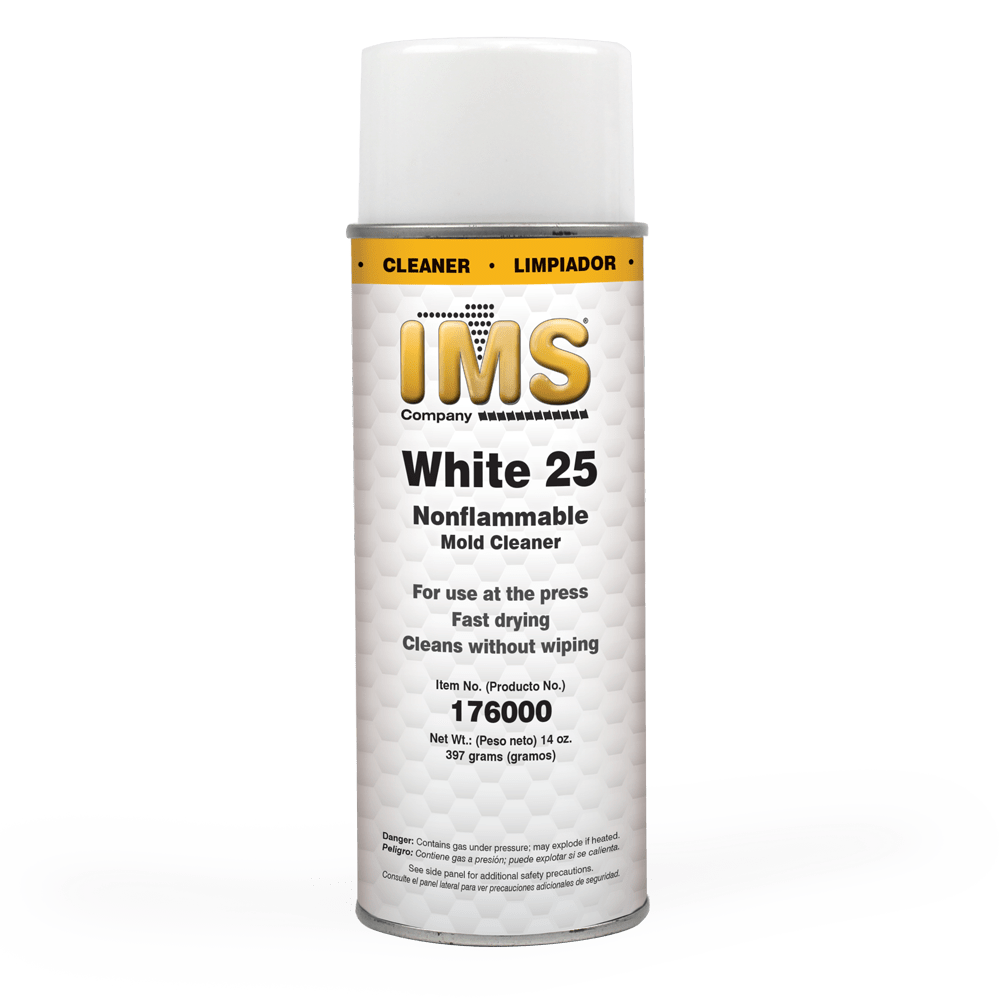

- Example Products: IMS Mold Cleaner White 2000 and Economy Mold Cleaner NEW formula IMS Mold Cleaner White 25 Coming Soon!

- Pros: Safer to use near hot molds or in enclosed areas.

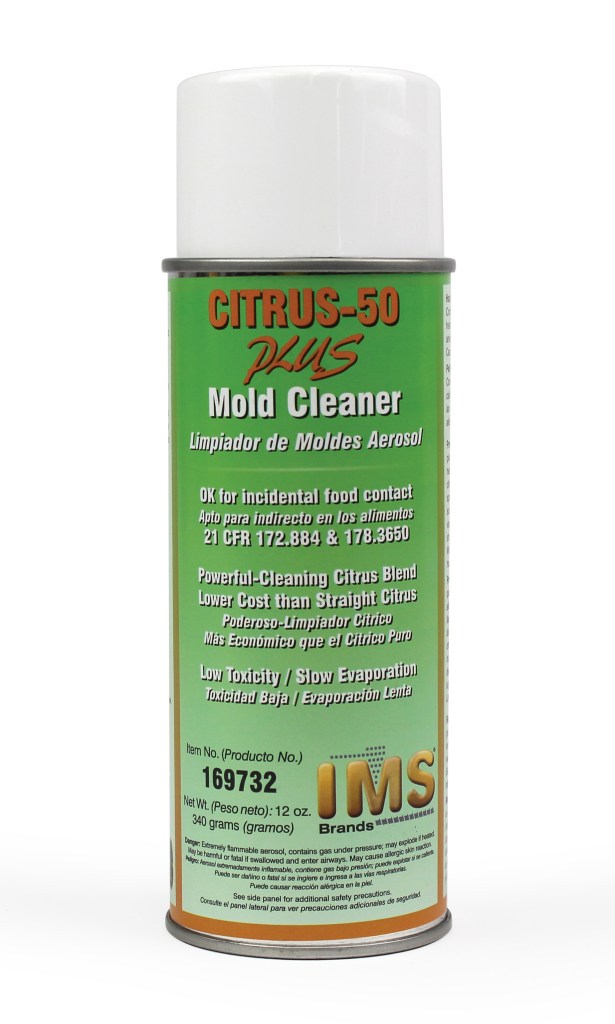

3. Citrus-Based or Bio-Based Mold Cleaners

- Use: Eco-friendly cleaning, often used for light to moderate residue.

- Example Products: IMS Citrus Spray, IMS SafeKlean Mold Cleaner, IMS Citrus 50 plus Mold Cleaner

- Pros: Lower toxicity, biodegradable.

- Cons: Less aggressive; not suitable for heavy buildup.

4. Foaming Mold Cleaners

- Use: Clings to vertical mold surfaces, allowing deeper penetration.

- Pros: Ideal for overhead or hard-to-reach mold areas.

- Example Products: IMS C-Foam Mold Cleaner

5. Dry Mold Cleaners / Air Dusters

- Use: Remove dry dust, plastic powder, or light debris.

- Pros: No drying time; safe for sensitive surfaces.

Cleaning Procedures

1. In-Press Cleaning (Quick Cleaning During Production)

Between short production runs or color/material changes.

- Steps:

- Open the mold.

- Spray solvent-based or non-flammable cleaner on the cavity/core.

- Wipe with lint-free cloth.

- Resume molding after full evaporation.

2. Offline Cleaning (Thorough Maintenance)

During scheduled downtime or mold changeovers.

- Steps:

- Remove the mold from the machine.

- Disassemble (if needed) for access to all surfaces.

- Clean with appropriate solvent or bio-based cleaner.

- Use soft brushes or non-metallic scrapers for buildup.

- Dry thoroughly and apply rust preventive (e.g., rust inhibitor spray).

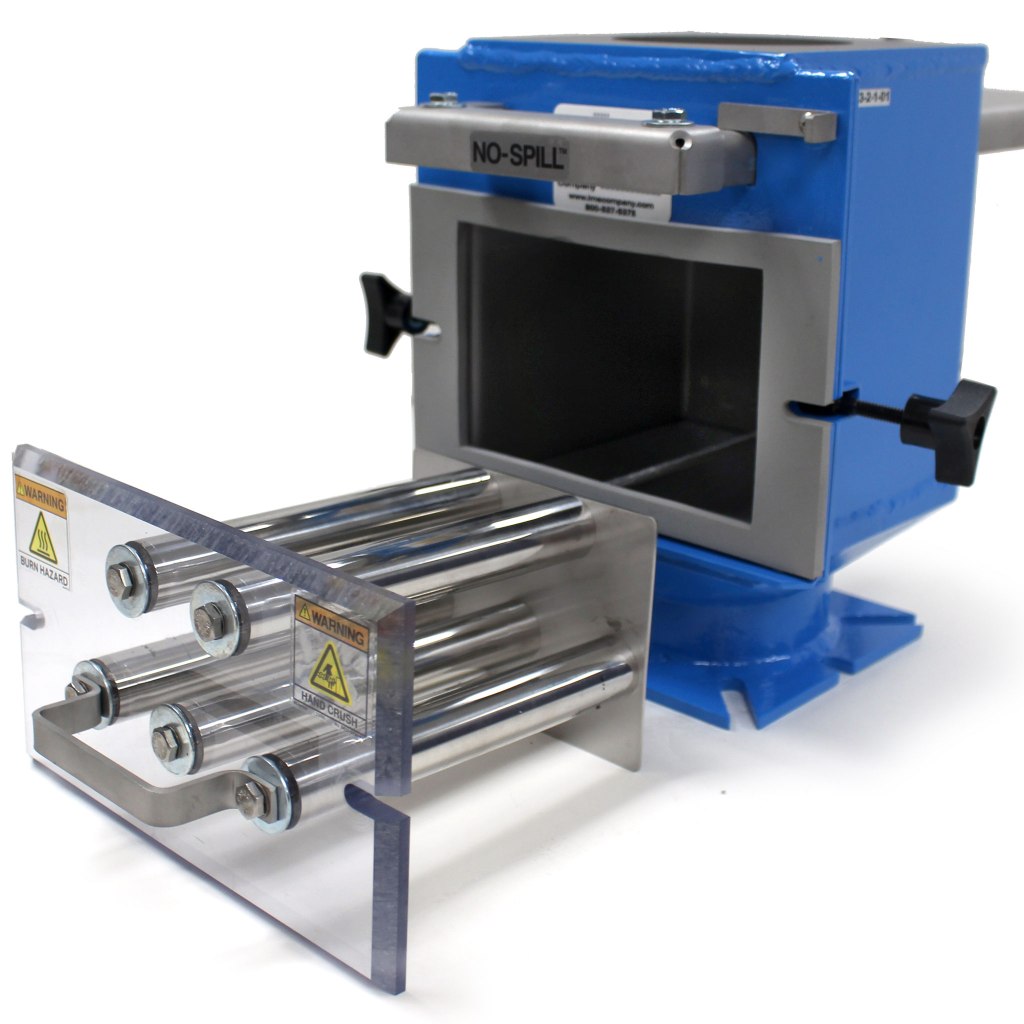

3. Ultrasonic Cleaning (for Small, Intricate Molds)

Deep cleaning of complex geometries or tiny vents.

- Method: Place mold inserts in an ultrasonic tank with cleaning fluid. Cavitation removes residue without abrasion.

4. Dry Ice Blasting (Non-Abrasive Heavy Cleaning)

For removing heavy buildup without damaging surfaces.

- Method: CO₂ pellets are blasted onto mold surfaces. No secondary waste, no disassembly needed.

Best Practices

Apply rust inhibitors after cleaning to prevent corrosion. Clean while the mold is still warm (but not hot) to loosen residue. Always follow the chemical cleaner’s SDS (safety data sheet). Use proper PPE—gloves, safety glasses, and masks if needed.

-

New Product Coming Soon

IMS Company is finalizing a new non-flammable formula to replace White 2000 and Economy Mold Cleaners.

Final shipping date is August, 2025! Quantities may be limited – get your orders in now!White 2000 Replacement

Available in July!

IMS Company is excited to unveil our newest Mold Cleaner: White 25! This TCE free cleaner is nonflammable, fast drying and cleans without wiping.

Available now:

Alternatives to White 2000

Hydrocarbon-based Red 2000 Mold Cleaner provides very good solvent properties, very fast evaporation and moderate toxicity.

- Low cost

- Cleans with little or no wiping

- Fast Evaporation

- Flammable

IMS Citrus-50 PLUS is a unique blend of our proven, natural citrus solvent and an FDA grade petroleum-based solvent.

- Low flammabiliy

- Helps avoid the price fluctuations that can be found in pure citrus cleaners

- Cleans with minimal wiping, saves labor time

-

Prepare Your Shop for Winter

Preparing an injection molding shop for the cold winter months requires both practical and strategic measures to ensure the machines and processes run efficiently despite the drop in temperature. Here are suggestions of actions you can take now.

1. Temperature Control

Inspect doors, windows, and walls for drafts and seal any gaps to retain heat. Ensure your heating system is serviced and functioning properly to maintain a consistent temperature in the shop. Consider installing space heaters or localized heating systems to keep machines at optimal operating temperatures. Follow all safety precautions when using space heaters.

2. Equipment Preparation

Switch to cold-weather lubricants for machines, as standard lubricants can thicken in colder temperatures, causing equipment to run less efficiently. Give machines extra warm-up time before starting production, especially on colder days. Cold temperatures can cause hydraulic fluids to become more viscous. Inspect hydraulic systems for leaks and service them to ensure they are ready for colder conditions.

3. Material Handling & Storage

Store raw materials in climate-controlled areas to prevent moisture absorption and changes in physical properties. Resins absorb moisture during colder months, so ensure proper drying before molding to avoid defects in the final product. Materials should be at a consistent temperature when fed into the machines. Cold materials can affect molding quality and cycle times.

4. Air System Maintenance

Air compressors should be checked for any signs of moisture accumulation, as cold air increases the chances of condensation, which can lead to freezing and damage. Ensure air dryers and filters are functioning properly to remove moisture from compressed air systems. If the relative humidity is low, have products on had to detect and neutralize static electricity.

5. Cooling Systems

Review coolant systems for proper antifreeze levels, especially if the system uses water-based coolants. Insulate coolant lines and pipes that are exposed to cold air to prevent freezing and bursting. Ensure that mold heating systems are working efficiently, as cooling the molds too quickly due to cold temperatures can lead to part defects.

6. Energy Efficiency

Consider insulating machines to retain heat, and use programmable thermostats to manage shop heating and cooling efficiently. Close doors quickly after deliveries and use barriers or air curtains to minimize heat loss. Contain and conserve barrel heat with IMS Exclusive UniVest® Barrel Insulation System. Barrel bands promote faster machine start-up and stop barrel heat fluctuations

7. Employee Safety & Comfort

Ensure employees have access to warm clothing and personal protective equipment suited for cold conditions. With snow and ice outside, ensure walkways are cleared and non-slip mats are installed at entry points to prevent accidents.

8. Planning for Delays

Anticipate delays in deliveries due to winter weather and stock up on essential materials and spare parts to minimize downtime. By taking these steps, you can help ensure that your injection molding shop operates smoothly and efficiently during the cold winter months.

Blog, Components, Gate Cutters & Trimmers, Heaters & Temperature Control, Industrial Equipment, Injection Molding, Material Handling, Mold Care, Mold Release & Maintenance, Molding Supplies, Nozzles & Nozzle Tips, Plastics, Post-Production Equipment, Production Equipment, Safety Supplies, Static Eliminating, Tech Tips, Uncategorized -

D-limonene

D-limonene, also known as citrus terpenes, is a chemical compound that can be found in the peels of citrus fruits like oranges, lemons, and limes. It has many uses, including as a solvent in cleaning agents, an aroma in furniture polish, a dietary supplement, and a flavoring in food and beverages. Every bit of the orange is used in production. After the orange is juiced the leftover peel is used to create orange extract and d-limonene.

Over the past few years producers are reducing the number of orange trees as their land becomes more valuable for other uses. The shift from orange cultivation to other land uses due to increasing land values is a significant issue in citrus-growing regions, including Brazil. Another issue, citrus greening, also known as Huanglongbing (HLB), and Yellow Dragon Disease (YDD) are both severe citrus diseases that have significantly impacted citrus production globally for almost 2 decades.

When you pair the long-term production decline with the chemical industry trying to move to greener, bio-based solutions like d-limonene your faced with a volatile situation. If you’re facing a shortage of d-limonene, here are a few strategies to consider:

- Alternative Solvents: Explore substitute d-limonene solvents for your process. For injection molding, solvents with similar properties might work, but it’s important to test first.

- Supplier Diversification: Look for alternative suppliers who have d-limonene available or who provide it in the quantity you need.

- Adjust Formulations: If possible, adjust your material formulations to reduce or eliminate the need for d-limonene.

- Inventory Management: Consider managing your inventory more carefully and planning your production schedules to make the most of what you have.

- Industry Collaboration: Reach out to industry groups to see if others are experiencing similar issues and if there are any shared solutions or resources available.

- Consult with Experts: Engage with experts or consultants who specialize in injection molding or materials science. They may provide insights or solutions tailored to your specific situation.

Mold Cleaners

Aerosol mold cleaners are commonly used in the injection molding industry to maintain and clean molds efficiently. These cleaners allow for easy application and targeted spraying to remove contaminants like dirt, grease, resin buildup, and other residues that accumulate. These cleaners are essential for maintaining the longevity and efficiency of molds in injection molding operations, ensuring consistent product quality and reducing downtime.

IMS Company Offers a Series of A Natural, Biodegradable Cleaners

IMS SafeKlean™

Most Environmentally Friendly Mold CleanerFDA rated GRAS — 21 CFR 182.60

Hydro Carbon based propellant

Lowest Flammability

Lowest Toxicity

Cleans with minimal wiping, saves labor time

Citrus Spray

Pure, all-natural cleaner with good solvent abilityFDA rated GRAS — 21 CFR 182.60

Hydro Carbon based propellant

Highly Flammable

Lowest Toxicity

Cleans with minimal wiping, saves labor time

Citrus Spray

Helps avoid citrus

price fluctuationsFDA rated 21 CFR 172.884 and 178.3650

Carbon Dioxide propellant

Flammable

Low Toxicity

Cleans with minimal wiping, saves labor time

-

Rust Prevention

8/14/2024

Rust prevention in injection molding is crucial for maintaining the longevity and performance of molds. Rust can cause defects in the molded parts, affect the accuracy of the mold, and lead to costly maintenance.

Whenever possible, use high quality materials such as stainless steel or other rust-resistant alloys for mold construction. Apply protective coatings or surface treatments like nitriding or chrome plating to enhance resistance to rust. Below are some effective types of coatings and treatments:

- Chromium Plating is a hard, corrosion-resistant coating applied to the surface of the mold. It provides excellent resistance to rust and wear, enhances durability and finish. This plating is ideal for molds exposed to aggressive environments.

- Nickel Plating offers good corrosion resistance and improved hardness. It can be used alone or as a base layer for other coatings. Suitable for molds requiring a combination of corrosion and wear resistance.

- PVD (Physical Vapor Deposition) Coatings is a process where thin layers of material (like titanium nitride or zirconium) are deposited onto the mold surface. They are used for high-precision molds and provide high hardness, low friction, and excellent corrosion resistance.

- Heat treatments such as nitriding or carburizing that harden the steel surface. They improve hardness and resistance to rust and wear. Suitable for molds where increased surface hardness and corrosion resistance are required.

- Ceramic Coatings offers excellent corrosion and wear resistance, high thermal stability. Ideal for molds exposed to high temperatures or aggressive chemicals.

- Anti-Corrosion Sprays or wipes containing rust inhibitors applied directly to the mold surface are easy to apply, provides temporary protection against rust. Used for short-term protection or as part of regular maintenance routines.

- Dry Powder Coatings applied electrostatically and then cured under heat. Provides a tough, durable finish with good corrosion resistance. Suitable for molds that are less frequently used or in environments where they are exposed to corrosive substances.

- Rust-Preventive Oils and Greases applied to the mold surface to form a protective layer. Provides effective, temporary protection against rust and corrosion. Commonly used for short-term storage or when the mold is not in use.

IMS Company’s Rust Preventative sprays create a protective layer on the mold surfaces, preventing rust and corrosion due to exposure to moisture or chemicals. They extend the life of the molds and simplify the maintenance of molds by keeping them in good condition and minimizing downtime.

Types of Rust Preventative Sprays

- Oil-Based Sprays: These sprays provide a thick, protective layer that is effective against moisture. They are often used for long-term storage.

- Water-Based Sprays: These are less greasy and can be more suitable for environments where cleanliness is a priority. They often contain additives to improve their protective qualities.

- Dry Film Lubricants: These sprays leave a dry film that can provide a protective barrier without being greasy, which is useful for high-precision molds.

Best Practices for Applying Coatings:

Ensure the mold surface is clean and free from contaminants before applying any coating. Always follow the manufacturer’s guidelines for applying and curing the coating to ensure optimal performance. Regularly inspect the coating for any signs of wear or damage and reapply as needed. Choosing the right rust preventative coating depends on factors such as the specific application of the mold, exposure conditions, and budget constraints. Combining these coatings with proper maintenance practices will greatly enhance the longevity and performance of injection molds.

- Regular cleaning of the molds to remove contaminants that can contribute to rust formation. Use non-abrasive cleaners that won’t damage the mold surface.

- Ensure that the mold is thoroughly dried after cleaning or exposure to water. Moisture can accelerate rusting. Employ desiccants or drying agents in storage areas to reduce humidity.

- Use rust inhibitors or anti-corrosion sprays on mold surfaces when they are not in use. Lubricate moving parts and components to create a protective barrier against moisture.

- Maintain a stable, low-humidity environment in the molding area and storage. Use dehumidifiers to control moisture levels in the workshop.

- Conduct regular inspections for early signs of rust and address them promptly. Follow a preventive maintenance schedule to address potential issues before they lead to rust.

- Avoid exposing molds to unnecessary moisture or harsh conditions during handling and transportation.

- Use protective covers or wraps when storing molds for extended periods. Store molds in a dry, temperature-controlled environment.

Implementing these practices will help in reducing the risk of rust and prolonging the lifespan of your injection molds.