IMS Company

A trusted partner for the plastics processing industry, offering a wide range of high-quality, process improving products at competitive prices. We are a diversified distributor specializing in supplies, components, auxiliary machinery, and equipment. With 75 years of industry experience, our stocked warehouse ensures fast, reliable delivery, helping you maintain peak production efficiency. Whether you need innovative products, expert support, or tailored solutions, IMS Company has the expertise and resources to keep your operations running smoothly. Visit us at imscompany.com for more!

For 75 years, one thing has never changed at IMS — our single-minded focus on providing products and services designed to help your shop increase efficiency and ramp up productivity.

Check out IMS on YouTube!

Blogs

July 28, 2025 – Why Keiba Gate Cutters Excel in Precision Cutting

June 3, 2025 – Sizing a Desiccant Dryer for Plastic Injection Molding

May 7, 2025 – Mold Cleaners

January 7, 2025 – Time to Purge

November 4, 2024 – Plant Shutdown

October 22, 2024 – Prepare Your Shop for Winter

September 11, 2024 – New Injection Press Setup

August 26, 2024 – D-limonene

August 14, 2024 – Mold Rust Prevention

July 9, 2024 – Mold Cleaner vs. Mold Release

March 25, 2024 – Part Diverting Systems

March 13, 2024 – Chill Out

February 22, 2024 – Why is Moisture a Problem

February 19, 2024 – What is a Vacuum Loader

February 5, 2024 – Injection Molding Nozzle Tips

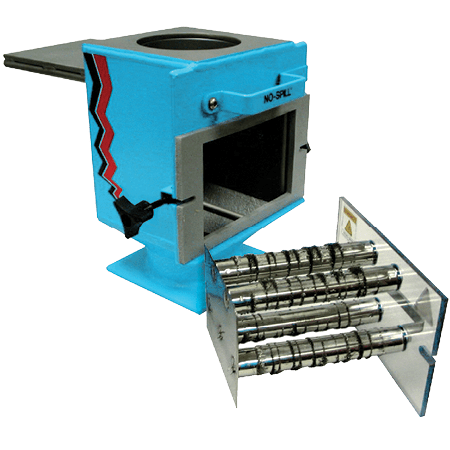

January 29, 2024 – Metal Separation

May 30, 2023 – Benefits of Insulation

April 22, 2023 – Sustainability

March 20, 2023 – Dew Point Meter/Monitor

March 2, 2023 – IMS Lime Buster

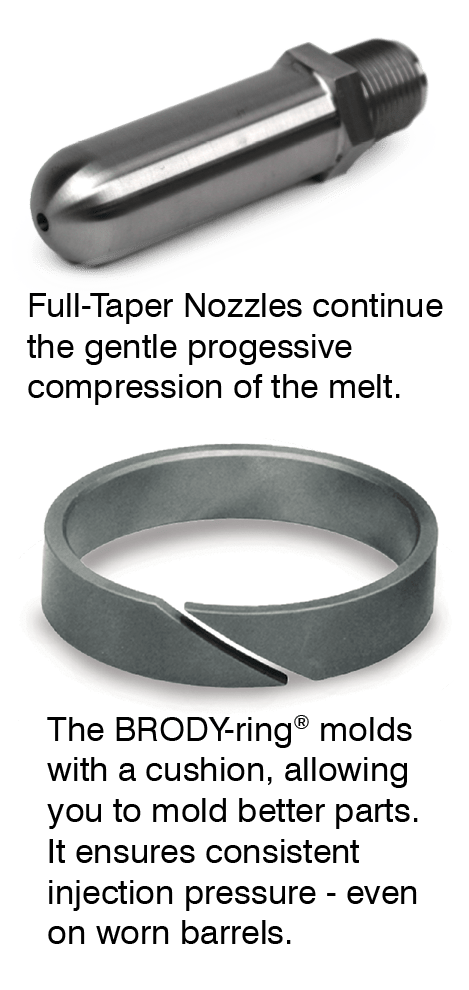

March 1, 2023 – IMS Brody Ring

January 30, 2023 – Clean Room Manufacturing

January 1, 2023 – Heater Band Wiring

December 21, 2022 – IMS Select Drum Tumbler

December 8, 2022 – Plastic Granulators

December 6, 2022 – Mold Setup Cart

November 28, 2022 – Eliminate Static and Dust

November 18, 2022 – Extending the Life of Your Heater Band

November 2, 2022 – How to Set Barrel Zone Temps

September 9, 2022 – The Benefits of Extruder Screens

August 24, 2022 – Calculating Heat Load for a Circuit

August 17, 2022 – Purgex Purging Compounds

August 12, 2022 – Air Wipe

August 11, 2022 – IMS Custom Projects

August 4, 2022 – New Shini Hopper Loader Systems

July 21, 2022 – Quick Change Fittings – Thread Profile Sizing

July 19, 2022 – IMS Custom Project

June 20, 2022 – Safety First

June 15, 2022 – IMS Screw Tip Brody Ring

June 15, 2022 – Screw Material Guidelines

June 15, 2022 – Screw Tip Wear Issues

June 15, 2022 – Essential Barrel Information

June 9, 2022 – Mold Safety Checklist

June 2, 2022 – Why Choose High Quality Desiccant?

May 26, 2022 – Circulators 101

May 19, 2022 – Sizing a Chiller

April 25, 2022 – Mold Temperature Control Product Selection

April 19, 2022 – Selecting the Right Gate Cutter For Your Job

April 12, 2022 – Barrel Insulation Blankets

April 4, 2022 – Quick Mold Change

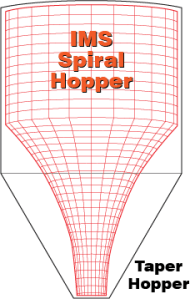

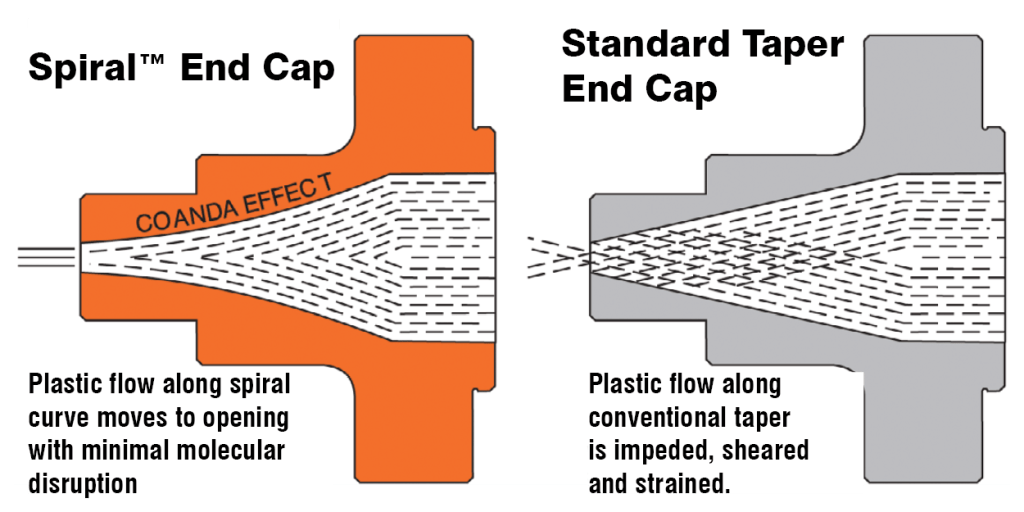

March 14, 2022 – Spiral Technology

February 17, 2022 – Screw Tips

-

Circulators 101

March 6, 2024

Circulators (Thermolators, Temperature Controllers) are essential components in injection molding processes, primarily utilized for controlling the temperature of molds so that as the part cools after injection, it maintains dimension, shape and structure – ensuring consistent quality and efficiency. Controlling the mold temperature is critical to good parts. You can get good melt flow, and the cavity can fill quickly and fully, but if the part is not cooled properly then a good melt flow means nothing.

Circulators need to be compatible with the injection molding machinery and seamlessly integrated into the overall manufacturing setup for efficient operation. Regular maintenance and monitoring of circulators are essential to ensure they continue to function optimally, thereby avoiding downtime and production delays. In advanced setups, circulators may be integrated into the overall automation system of the injection molding process, allowing for real-time monitoring and control of temperature parameters.

Here’s how circulators are typically used in injection molding:

- Cooling: Cools the molds after each cycle. Rapid cooling is essential for improving cycle times and overall productivity.

- Heating: In some cases, circulators may also be used for heating the molds to specific temperatures.

- Thermal Stability: Ensure thermal stability throughout the injection molding process, which is crucial for preventing defects and maintaining part quality.

- Energy Efficiency: Modern circulators often come with energy-saving features to optimize energy consumption during the temperature control process, contributing to cost-effectiveness and sustainability.

- Process Optimization: By precisely controlling the temperature of molds, circulators play a vital role in optimizing the process for different materials and product specifications.

Overall, circulators play a critical role in maintaining temperature control and ensuring the quality, efficiency, and reliability of injection molding operations. Their proper selection, installation, and maintenance are essential considerations for any injection molding facility.

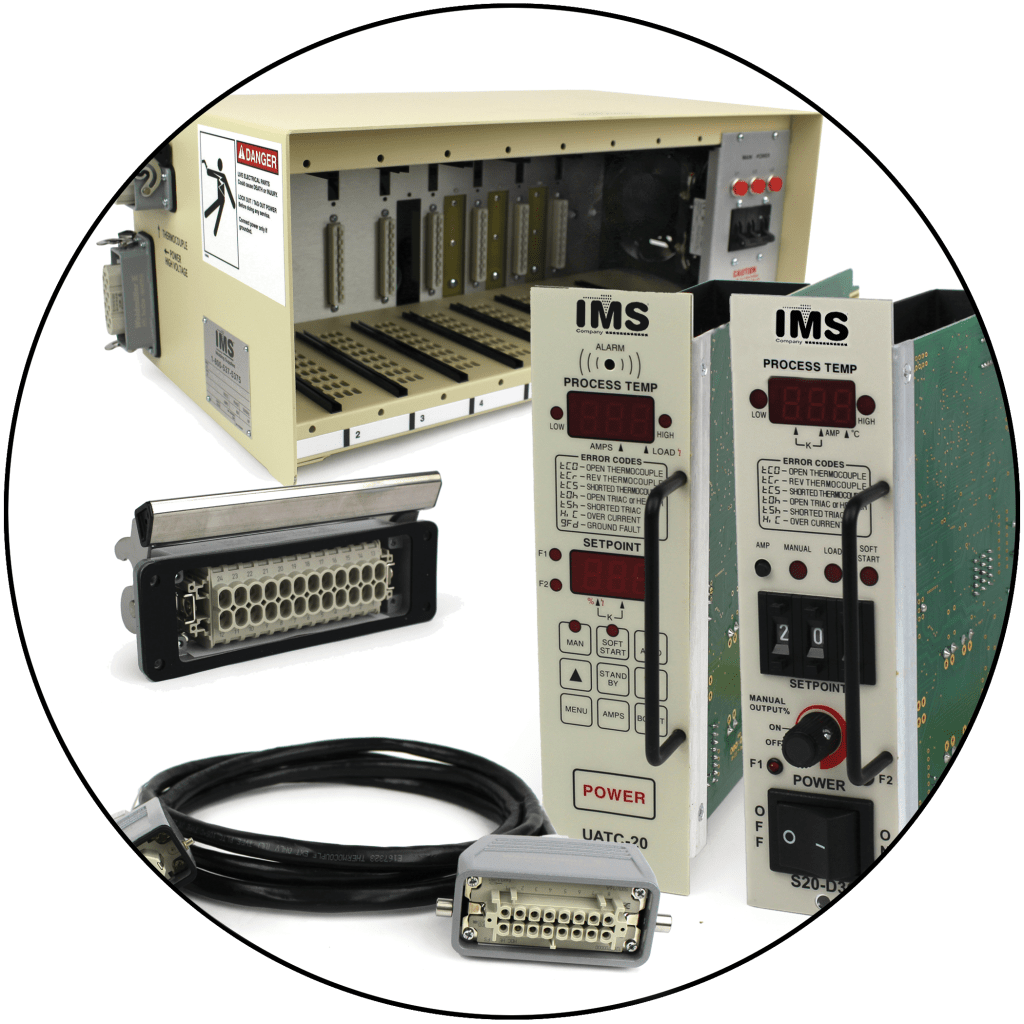

IMS offers several options for temperature control needs: Circulators, Mold Temperature Controllers

You May Also Need:

Heat Transfer Fluids

A Quick Comparison Of Heat Transfer Mediums

• Water — Limited use range: 32° to 212°F. Encourages corrosion.

• Uninhibited Glycols — Allow temperatures to 250°F, but 2½ times more corrosive than water, if not neutralized.

• Automotive antifreeze — Contains corrosion inhibitors, but can foul heat transfer surfaces in less turbulent systems.

• UG-10 Ethylene Glycol — Low silicate formula provides good corrosion protection at a relatively low price.

• EG-17 Ethylene Glycol — Industrial inhibitors coat surfaces and impact pH for maximum corrosion protection.

• Pro-17 Inhibited Propylene Glycol — Non-Toxic Heat Transfer Fluid With Maximum Protection Against Acidity and Corrosion.

• PG-1 Hi-Heat Transfer Fluid — The Ultimate, Non-Toxic Fluid For Non-Pressurized Heating To 600°F.

• FF-1 Oil System Flushing Fluid — Improves heat transfer for faster cycles.

• PSC Plus Oil System Cleaner — Maximizes heat transfer for more parts and increased quality.In addition, how efficiently any of the above units work is directly tied to how clean your mold passages are. Any buildup of scale can affect the transfer of heat. The passages need to be checked and maintained regularly. To help with that, IMS offers the Limebuster which helps remove the scale buildup in mold passages. Just 1/64″ of scale can reduce the heat transfer rate up to 40%. Using an acid/water mixture, the fluid is circulated by a low pressure pump. The fluid helps dissolve the scale slowly so good heat transfer can return. This type of unit also is used to clean heat exchangers.

While the above is basic in its presentation, the message is clear; IMS understands and can help. IMS has the expertise and the equipment to help maintain and even improve your process. Good parts and reduced scrap means you make money.

That is what we are here to help with. Call IMS Today for all your Injection Molding needs.

-

Understanding Mold Cleaner and Mold Release

Mold Cleaner and Mold Release are two distinct products, each serving different purposes:

7/9/2024

Mold Cleaner

- Purpose: Mold cleaners are used to remove residues, contaminants, and deposits from the mold surfaces.

- Usage: They are applied during mold maintenance to ensure the mold remains clean and free from substances that could affect part quality or mold performance.

- Types: Mold cleaners come in various formulations depending on the type of residue they need to remove (e.g., plastic residue, grease, rust inhibitors).

IMS Company offers an extensive line of Mold Cleaners for all of your Injection Mold needs. Choose from heavy duty solvents that clean without wiping for use at the press, aerosols with low-toxicity for the maintenance area, cleaners that are non-flammable and degreasers that are naturally biodegradable.

Mold Release

- Purpose: Mold release agents are applied to the mold surface to prevent the molded part from sticking to the mold cavity or core.

- Usage: They facilitate easy release of the molded part from the mold, reducing cycle time and minimizing the risk of damaging the part during removal.

- Types: Mold releases can be water-based, solvent-based, or dry lubricants, depending on the molding process and materials used.

The right Mold Release is critical – it has an effect on part quality and cycle time and make a huge difference in job profitability.

Key Differences:

- Function: Mold cleaner cleans the mold surface, while mold release prevents adhesion of the molded part to the mold.

- Application: Mold cleaner is used during maintenance to clean existing molds, whereas mold release is applied during molding cycle to facilitate part release. Depending on many factors, mold release may need to be applied anywhere from every cycle to once a day.

- Effect: Mold cleaner ensures mold cleanliness and performance, while mold release ensures smooth part ejection and reduces defects.

In summary, Mold Cleaners and Mold Releases serve complementary but different roles in the injection molding process, addressing cleanliness and ease of part release, respectively. Each is crucial in maintaining efficient and high-quality production in injection molding operations.

-

Part Diverting Systems

Automatically Sort Bad Parts From Good Parts

3/25/2024

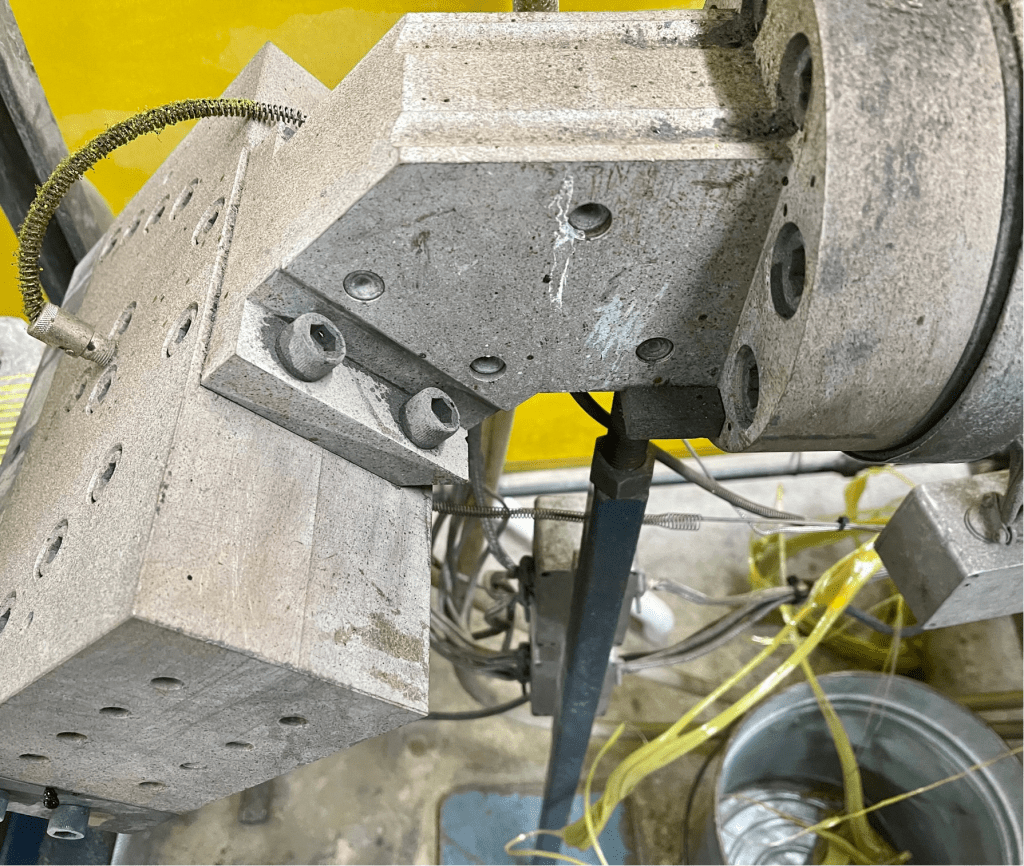

General Description: A part diverter is used to change the direction of a shot of parts, the discharge of a complete cycle or cycles of parts from an injection molding machine. IMS offers two different styles of part diverters (also known as “part discriminators” in the injection molding industry) custom built to your specifications.

- 1) Under the press part diverters: Units sit or hang directly from the injection molding machine and based upon a specified signal from a IMM or process controller a pneumatically operated tipping tray internal to the diverter housing will discharge parts out the opposite end from where all “Good” shots discharge. The two different styles of under press part diverters are a free standing unit and a quick change type:

A) Free standing S1: The free standing S1 diverter is either a square or rectangular stainless steel housing with an internal pivoting tray actuated by a pneumatic air cylinder positioned either under the internal tray, or alongside the housing. The unit is typically supported by a mild steel T-type support stand that is 20” tall and allows the housing to adjust vertically. An air control kit consisting of a ready to mount plate supporting a solenoid valve with filter and regulator/gauge and ¼” air hose from air valve to cylinder is included. Optional chute extensions in standardized lengths are available to add to the housing on either side to aid in part discharge.

B) Quick Change Rail S1: The quick change rail S1 type is a square or rectangular stainless steel housing with an internal pivoting tray actuated by a pneumatic air cylinder positioned either under the internal tray, or alongside the housing. This unit is typically supported by an optional QCRA1 or QCRA2 quick change rail attachment kit for either press depths up to 36” or 48” deep. The rail attachments support the load and provide for easy installation, removal or movement. An air control kit consisting of a ready to mount plate supporting a solenoid valve with filter and regulator/gauge and ¼” air hose from air valve to cylinder is included.

Optional chute extensions in standardized lengths are available to add to the housing on either side to aid in part discharge. Many other options are available.

Free Standing

Conveyor Mounted

2) Conveyor Mounted Part Diverters: IMS offers 6 different orientations for conveyor mounted parts diverters. These are used either at the in-feed or discharge end of the conveyors. Four of them may be used with a flat or cleated type conveyor belts. Uses at the in-feed end of a conveyor are primarily when the IMM cycle time is very fast, and/or where a reversing belt conveyor may not be feasible. Primary use at the discharge end is when the good part container and bad part container need to be on the same side of the IMM.

A) PD1: Pneumatically operated rail that has a pivot point and an air cylinder to angle the rail across the belt surface to side discharge the product. Includes air control kit. This is for non-cleated belts only, must use slider bed on conveyor frame and hard durometer belt surface.

B) PD2: Similar to PD1 without the pneumatic controls. PD3: QCRS1 housing in standard dimensions with flanged bottom to mount to either the conveyor frame or the side rails, when using a top return on rails. The unit is mounted at the in-feed end and directs products in the direction of belt travel for good parts and off the end of the conveyor for rejected parts. Includes air control kit package.

D) PD4: QCRS1 style housing in standard dimensions with flanged bottom or flanged top to mount with special brackets to the discharge end of the conveyor, which may be the drive end or the idle end. The unit is mounted at the discharge end and directs the flow of products in the direction of belt travel for good parts and off the end of the conveyor for rejected parts. Includes air control kit package.

E) PD5: QCRS1 style housing in standard dimensions with flanged bottom to mount to either the conveyor frame or the side rails, when using a top return on rails. The unit is mounted at the in-feed end and directs the flow of products perpendicular to the direction of belt travel. Includes air control kit package.

F) PD6: QCRS1 style housing in standard dimensions with flanged bottom or flanged top to mount with special brackets to the discharge end of the conveyor, which may be the drive end or the idle end. The unit is mounted at the discharge end and directs the flow of products perpendicular to the direction of belt travel. Includes air control kit package. - 1) Under the press part diverters: Units sit or hang directly from the injection molding machine and based upon a specified signal from a IMM or process controller a pneumatically operated tipping tray internal to the diverter housing will discharge parts out the opposite end from where all “Good” shots discharge. The two different styles of under press part diverters are a free standing unit and a quick change type:

-

Chill Out!

Chillers in the Injection Molding Process

March 13, 2024

Chillers enable manufacturers to produce high-quality parts efficiently and cost-effectively. A chiller is a piece of equipment used to control and maintain the temperature of the mold during the manufacturing process. It works by circulating a coolant, typically water or a water-glycol mixture, through channels within the mold to absorb heat generated by the molten plastic.

Chillers are typically connected to the injection molding machine and the mold itself through a network of hoses or pipes. They regulate the temperature of the coolant to ensure that it remains within the specified range, which is critical for achieving the desired quality and consistency of the molded parts. They come in various sizes and configurations, depending on your specific requirements. Some features may include temperature controls, flow rate adjustments, and monitoring systems to optimize performance and efficiency.

Chillers play a crucial role for several reasons:

- Temperature Control: Injection molding requires precise temperature control to ensure the quality and consistency of the molded parts. Chillers help maintain the temperature of the mold at the desired level, preventing overheating or undercooling, which can lead to defects in the final product.

- Cooling Time Reduction: Proper cooling is essential for the solidification of the molten plastic inside the mold. Chillers help reduce the cooling time by efficiently removing heat from the mold, allowing for faster production cycles and increased productivity.

- Prevention of Warping and Shrinkage: Rapid and uniform cooling facilitated by chillers helps prevent warping and shrinkage of the molded parts. This ensures that the final products meet dimensional requirements and have consistent quality.

- Consistency and Reproducibility: Maintaining consistent temperature conditions throughout the injection molding process is crucial for producing parts with uniform properties and dimensions.

- Extended Tool Life: Heat can accelerate wear and tear on injection molds, leading to shorter tool life and increased maintenance costs. By keeping the molds cool, chillers help prolong the life of the molds, reducing downtime and replacement expenses.

The Right Type

Most refrigeration is designed for static loads, like in a meat cooler. In plastics processing, heat is added to and removed from the mold during every cycle. Select a chiller designed for active heat loads.

The Right Size

Although an undersized chiller will cost less to buy, the chiller will be running at full capacity, resulting in higher operating costs. And even then, you may have trouble consistently keeping the mold cold. Read more in our blog: How to Size a Chiller.Overall, chillers play a vital role in the injection molding process by facilitating proper cooling of the mold, which helps prevent defects, ensures dimensional accuracy, and enhances the overall production efficiency.

-

Why is Moisture a Problem

In the Injection Molding Process

2/22/2024

Molding problems, particularly in humid months, often trace back to excessive moisture in the resin. Moisture in resin can cause degradation of certain materials used in injection molding, particularly hygroscopic plastics like nylon, ABS, and polycarbonate. It can lead to discoloration, molecular degradation, resulting in defects such as brittleness, reduced strength, surface imperfections and other undesirable effects in the final molded parts. This can lead to parts that are more prone to failure or deformation under stress.

Moisture absorption can affect the dimensional stability of the plastic during the molding process, leading to variations in the size and shape of the molded parts. This causes dimensional inaccuracies and warping, leading to deviation from the intended specifications and making them unfit for their intended application. The presence of moisture can cause variations in melt viscosity, flow behavior, and cooling rates, leading to inconsistencies in the molding process and resulting in fluctuations in part dimensions and properties.

To mitigate these issues, it’s essential to properly dry the plastic resin before the injection molding process. This is typically done using equipment such as desiccant dryers or hopper dryers, which remove moisture from the resin pellets prior to molding. Additionally, maintaining proper storage conditions for the resin, such as humidity-controlled environments and sealed containers, can help prevent moisture absorption before processing.

Desiccants can play a crucial role in injection molding processes, particularly when dealing with moisture-sensitive materials such as certain types of plastics. Desiccant captures moisture in its pores, which become blocked with contamination over time. And only fresh desiccant gives your dryers a chance to thoroughly dry your material in hot, humid weather. Dew Point Meters monitor and spot check the performance of the desiccant style drying equipment. Here’s how desiccants are typically used in injection molding:

- 1. Material Storage: Plastic pellets, can absorb moisture from the atmosphere over time. Desiccants are often used in material storage areas or containers to maintain low humidity levels and prevent moisture absorption by the plastic pellets.

- 2. Drying Hoppers: Before the plastic pellets are fed into the injection molding machine, they may need to be dried to remove any moisture absorbed during storage or transportation. Drying hoppers equipped with desiccant dryers are commonly used for this purpose. The desiccant absorbs moisture from the pellets as they are heated and dried before entering the molding machine.

- 3. Dehumidification Systems: In environments with high humidity levels, it may be necessary to use dehumidification systems to control the moisture content of the air within the injection molding facility. Desiccants can be incorporated into these systems to help remove moisture from the air, creating a dry environment conducive to high-quality molding.

- 4. Material Handling Equipment: Desiccants can also be integrated into conveyors or drying systems, to prevent moisture absorption during the transfer of plastic pellets between different stages of the injection molding process.

- 5. Mold Storage: Molds can also be susceptible to moisture-related issues if not stored properly. Desiccants can be used within mold storage containers or cabinets to maintain low humidity levels and prevent corrosion or other damage to the molds.

Overall, the use of desiccants in injection molding is essential for ensuring the quality and consistency of molded products, particularly when working with moisture-sensitive materials. By effectively controlling moisture throughout the molding process, manufacturers can minimize defects and optimize production efficiency.

-

What is a Vacuum Loader?

2/19/2024

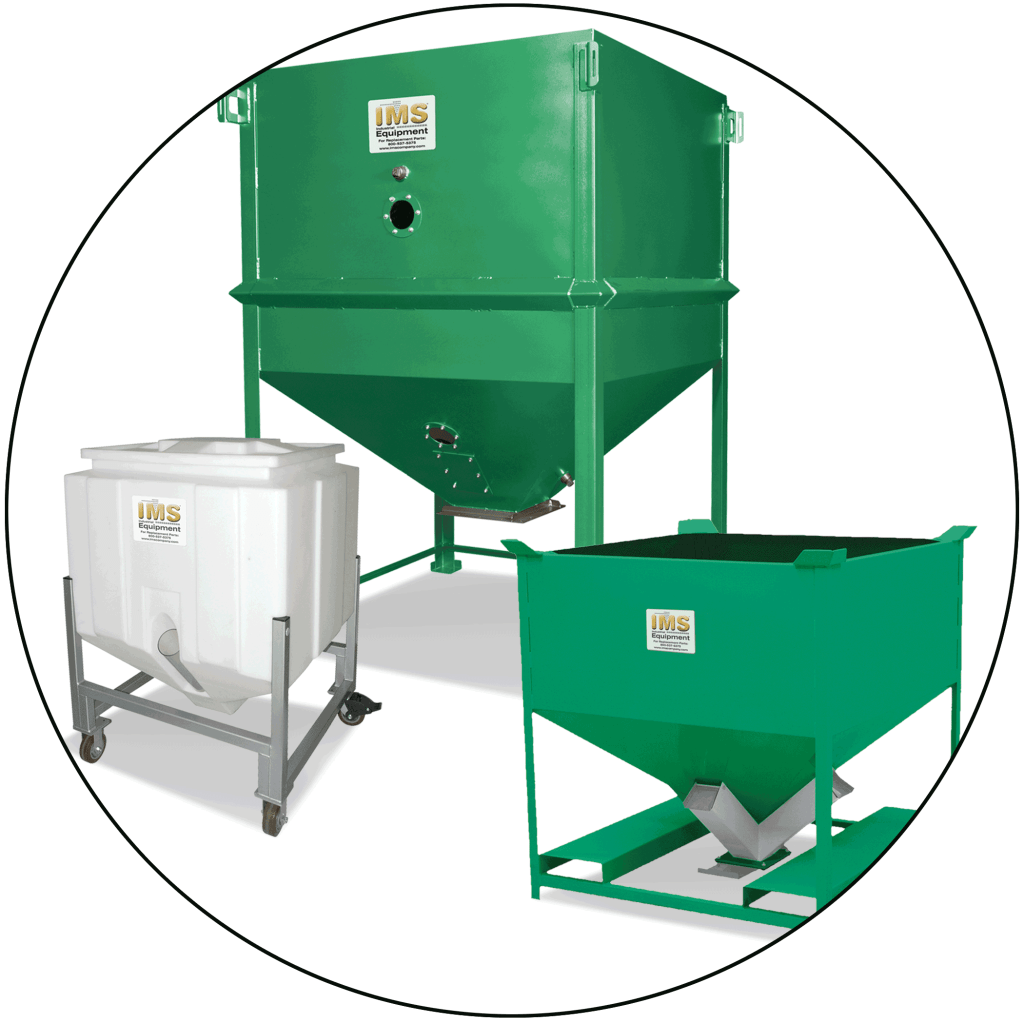

Vacuum or Hopper Loaders automate the feeding of raw material, such as plastic pellets or resin, from a storage container to the injection molding machine’s hopper. This process ensures a continuous supply of material without the need for manual intervention. This automation not only improves efficiency but also minimizes the risk of errors and inconsistencies in material feeding.

Vacuum loaders transport various types of materials over long distances. They are often equipped with filters or screens to prevent contaminants such as dust, debris, or foreign particles from entering the molding machine. This helps maintain the quality and integrity of the final molded products. Newer model vacuum loaders may come with advanced control systems that allow operators to monitor and adjust feeding parameters such as flow rate, material type, and hopper level. This level of control enables fine-tuning of the injection molding process for optimal results.

Another benefit is minimizing material waste by accurately measuring and delivering the required amount of material to the machine. This can lead to cost savings for by reducing material losses and improving overall efficiency.

Overall, vacuum loaders play a critical role in optimizing the injection molding process by automating material handling, improving efficiency, and ensuring consistent quality in the final products. Their integration into injection molding systems has become standard practice in modern manufacturing facilities. There are several types of vacuum loaders commonly used in injection molding:

- Self-contained: Have a built-in vacuum pump and are designed to be mounted directly onto the molding machine’s hopper. They are compact and easy to install, making them suitable for smaller injection molding setups.

- Central Vacuum Systems: Often used in larger facilities. Consist of a centralized vacuum pump and a network of pipes that deliver resin pellets from multiple storage bins to various molding machines throughout the facility. Central systems offer greater flexibility and efficiency in material handling.

- Venturi Loaders: Utilize compressed air to create a vacuum for conveying resin pellets. They are compact and easy to install, making them suitable for smaller molding operations. However, they may not be as efficient as other types of vacuum loaders and are typically used in lower-volume applications.

- Positive Displacement Loaders: Positive displacement loaders use a rotary valve or similar mechanism to move resin pellets from the storage hopper to the molding machine’s hopper. They are particularly useful for handling abrasive or fragile materials and are often preferred in high-volume injection molding operations due to their reliability and efficiency.

- Powder Loaders: While primarily used for conveying powders in processes like powder coating or pharmaceutical manufacturing, powder loaders can sometimes be adapted for use with injection molding processes, particularly when dealing with specialty materials or additives in powder form.

- Gravitational Vacuum Loaders: Rely on the force of gravity to move resin pellets from a higher elevation (storage hopper) to a lower elevation (molding machine hopper). They are simple in design and suitable for applications where a small amount of material needs to be conveyed over short distances.

Each type of vacuum loader has its advantages and is suitable for different applications depending on factors such as the volume of material to be conveyed, the distance it needs to travel, and the specific requirements of the injection molding process.

-

Injection Molding Nozzle Tips

2/5/2024

In injection molding, the nozzle tip is a critical component in the process. It plays a key role in controlling the flow of molten plastic into the mold cavity to create the desired product. Here are some important features:

- Material Compatibility – typically made from materials that can withstand the high temperatures and pressures involved in the injection molding process. Common materials include hardened steel, tool steel, or other alloys.

- Design and Shape – affects the flow and distribution of molten plastic. May have a tapered or conical shape to facilitate smooth material flow.

- Size and Diameter – should be chosen based on the specific requirements of the molding process, including the type of material being used and the design of the mold.

- Temperature Control – some come with built-in temperature control to help maintain the optimal temperature preventing premature solidification and ensuring proper flow.

- Wear Resistance – subject to wear due to the abrasive nature of molten plastics. Wear-resistant coatings or materials may be applied to extend the life of the nozzle tip.

- Shut-off Mechanism – prevent drooling or dripping of molten plastic after the injection cycle. This is particularly important for maintaining the quality of the molded parts.

- Cleanability – essential for efficient operation and maintenance of the machine.

- Compatibility – must be compatible with the specific type of material being used. Different materials may require different designs to ensure optimal performance.

- Quick Change Systems – Some injection molding systems incorporate quick-change systems for nozzle tips. This facilitates easier maintenance, cleaning, and replacement.

- Alignment with Mold Design – should align with the mold design to ensure proper filling and packing of the mold cavity.

IMS precision made Nozzle Tips are designed from high quality, heat-treated tool steel and are perfect for everyday use in the molding shop. The technicians at IMS have worked hard to bring you quality at an affordable price.

At IMS, we put our customers’ satisfaction as the highest priority. When it comes to our nozzle tips, we think you will agree that they are a great value.

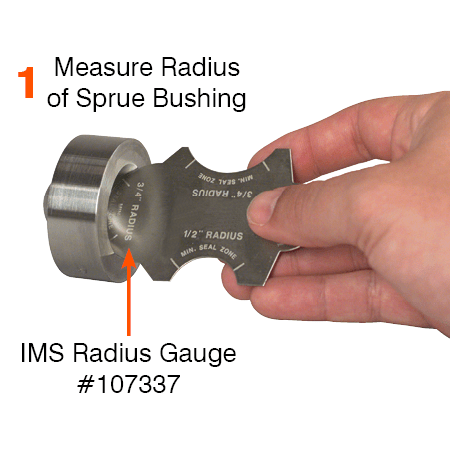

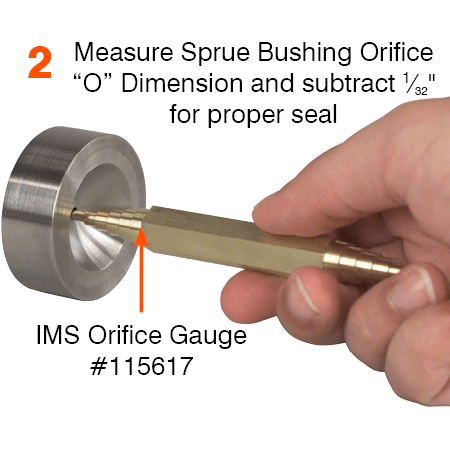

Before Ordering, Please Gather the Following Dimensions:

If your application requires higher wear resistance, sizes not listed, etc. please contact an IMS technician for a prompt quote, see the “Request for Quotation Form”

Beryllium Copper: Nozzle tips made of heat treated beryllium copper ensure maximum heat transfer plus strength and toughness. Beryllium Copper nozzle tips will help prevent tip freeze-ups, will let you lower nozzle temperature, and will enable electrical use reduction while shortening cycle times. NOTE: Beryllium Copper Nozzle Tips are not recommended for use with abrasive materials.

Here are 10 reasons to buy IMS nozzles:

- 1. Guaranteed to meet our certified material and hardness requirements.

- 2. Machined using state-of-the-art machines by experienced technicians who use the most up-to-date practices; be assured they are made with care and quality.

- 3. Finished to perfection using hand polishing.

- 4. Protected from rust and corrosion.

- 5. Protected from thread damage and nicks.

- 6. Stamped with sizes and styles for easy re-ordering.

- 7. Tested using the latest computerized measuring and checking equipment.

- 8. Quality inspected in our facility using the strictest approval practices.

- 9. Your satisfaction is guaranteed!

It’s important to follow the manufacturer’s guidelines and recommendations for the specific machine and material being used to ensure the nozzle tip functions effectively and efficiently. Regular maintenance and inspection of the nozzle tip are also crucial for optimal performance and longevity of the injection molding equipment.

-

Metal Separation

Separation of metal contaminants is essential in plastics processing. Tramp Metal in the production line is not only a risk to the consumer, but also to equipment. Metal separation in plastics processing offers several benefits, contributing to the efficiency, quality, and safety of the overall plastic manufacturing process. Here are some key advantages:

1/29/2024

- Final Product Quality and Compliance – Many industries, such as food packaging, automotive and medical, are subject to regulations and standards regarding the quality, purity, and safety of their products. Metal separation ensures that the final products meet those standards.

- Consistent Processing – The presence of metal can lead to inconsistent melting and molding, affecting overall process stability. Removing metal ensures a more uniform and consistent processing of plastic materials.

- Cost Savings & Environmental Impact – Metal separation lowers the risk of damage to equipment, improves process efficiency, and reduces the risk of rejected product, reducing the amount of waste generated.

- Process Optimization & Enhanced Safety – Metal separation ensures that the process operates at its highest efficiency, with minimal disruptions. It also enhances workplace safety by reducing the risk of accidents or malfunctions caused by metal particles in the equipment.

- Customer Satisfaction – Consistently delivering high-quality, contaminant-free products improves customer satisfaction and builds trust in the brand. This can lead to increased customer loyalty and a positive reputation in the market.

HOW METAL DETECTORS WORK

The product passes through an opening in the detector, which houses a unique three-coil search head. This is comprised of windings around an aperture opening. The transmitter is in the center of this coil with two receivers surrounding it, one placed at the entrance head and one at the exit. When a piece of metal passes through the coil opening, a signal is generated, calculated and activates further operations or devices. Some metal detectors are equipped with automatic reject mechanisms, which isolate contaminated material and remove it from the product flow. Within the aperture opening, an electromagnetic field is created.

It’s important to note that the specific design and technology of metal detectors can vary among manufacturers, but the underlying principles are generally based on electromagnetic induction or eddy currents. Here’s a brief explanation of how they work:

Metal detectors consist of a coil through which an alternating current flows. When a metal object passes through the detector, it disrupts the electromagnetic field generated by the coil. This disruption induces eddy currents in the metal object, creating a secondary magnetic field. The detector senses the change and triggers an alarm to alert operators about the presence of metal.

An alternating magnetic field is generated by a coil in the detector. When a conductive metal object passes through this field, it induces eddy currents in the metal. The eddy currents, in turn, create their own magnetic field that opposes the original magnetic field. The detector reacts to this change and signals the presence of metal.

Drawer Magnets

The drawer magnet is installed in the processing line, usually to a hopper or chute through which the plastic material flows. The magnetic drawer is positioned to attract and capture any ferrous particles present in the material. Periodically, the drawer magnet needs to be cleaned to remove the accumulated contaminants. This is typically done by removing the drawer from its housing and wiping or scraping off the captured ferrous particles.

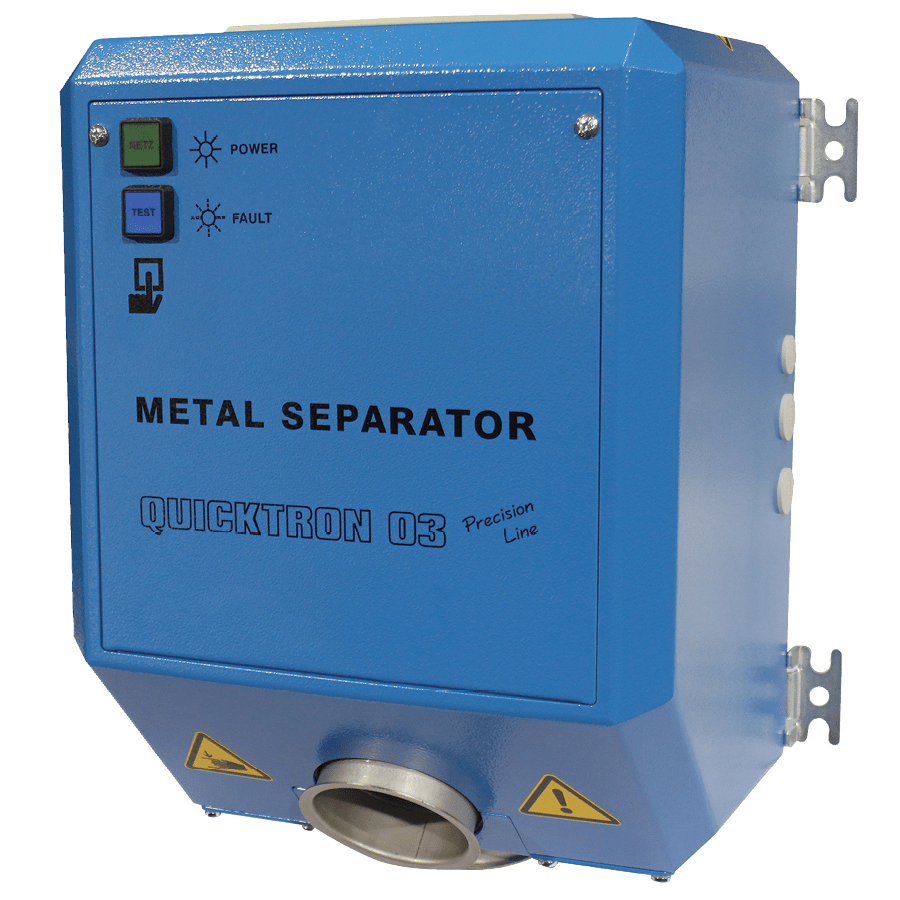

Pre-Production All-Metal Detectors

Gravity free-fall metal detectors are commonly used in industries such as food processing and packaging to ensure that metal contaminants are detected and removed from the product stream. They are designed to detect metal particles in free-falling bulk materials, such as plastic granules, as they pass through the detection zone. The high-speed reject mechanism is responsible for removing any contaminated material from the production line with minimal good material diversion.

Machine Mounted All-Metal Detectors

Provides efficient detection and rejection of both ferrous and nonferrous metal within all materials, without process interruptions. Designed especially for choke-feed applications it can bolt directly to the infeed of processing equipment and support the weight of hoppers on an injection molding machine or extruder. Fast, precisely timed pneumatic rejection mechanism results in accurate cycling and conservation of good material. Available in a high-temperature version suitable for handling product at higher-than-normal temperatures (up to 350°F.)

When considering a metal detector for plastic processing, it’s essential to choose one that meets the specific requirements of your application, including sensitivity to detect the desired metal contaminants and a reject mechanism suitable for handling plastic materials.

-

Benefits of Insulation

5/30/2023

Inflation is defined as the rate of increase in prices over a given period of time. It is typically a broad measure, such as the overall increase in prices or the increase in the cost of living in a country. For the past two years, the US has experienced an inflation rate higher than the long term average of 3.28%. This has lead businesses to experience higher costs, especially higher energy costs.

In a previous blog (Barrel Insulation Blankets), IMS discussed the benefits of wrapping your barrels in insulation vests. It has been well documented that insulating your injection or extrusion barrels keeps the heat applied with heater bands or cast heaters can remain in the barrel. By reducing heat loss, energy costs are reduced.

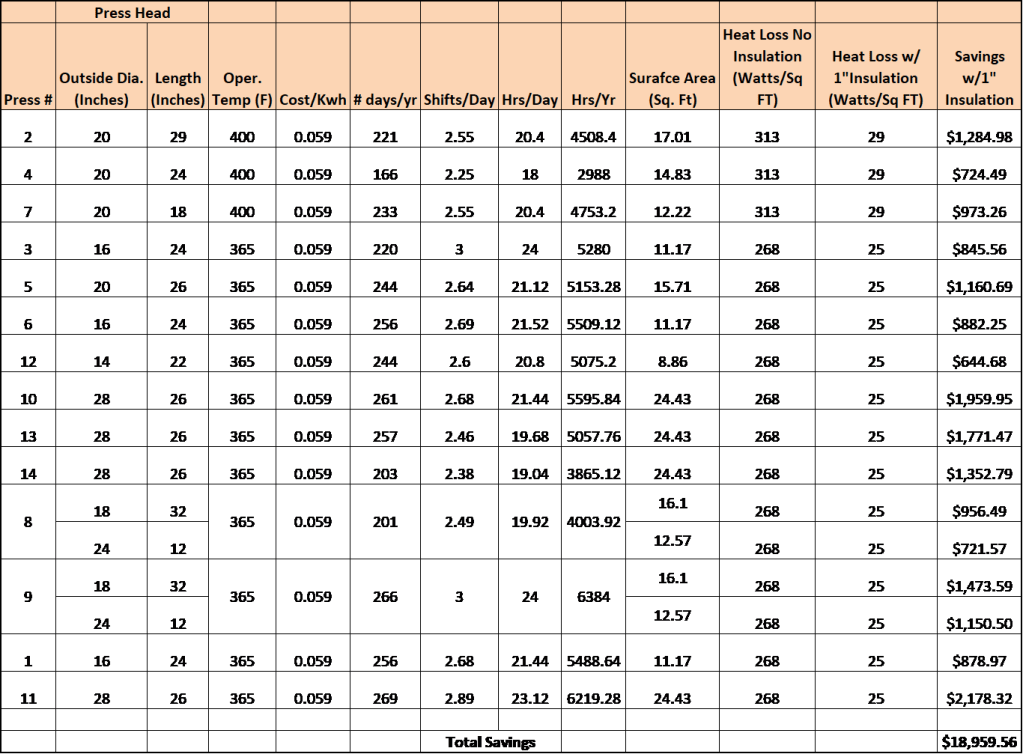

I personally conducted an analysis of savings for a customer after a visit to their facility to assess the situation. The results are chronicled below:

The above savings reflected wrapping their barrels in 1” fiberglass insulation blankets. The chart demonstrates that taking into account current electrical rates, combined with kilowatt hour usage, the customer was in line for substantial savings.

The energy saving possibilities do not end there. Extruders can wrap their dies in insulation blankets, or depending on the die configuration, white insulation board. The insulation board is rigid in nature and can be cut to fit any type of die (example below).

Insulation board is fitted to each die surface. The board retains

the die heat and makes the extrusion process more efficient.This insulation board can also be mounted to the surfaces of injection molds to control mold sweating and retain heat.

Finally, IMS can supply insulation for items such as gate valves, large tee connections, and any other large plumbing connection.

This is where the expertise IMS offers can help molders and extruders achieve desperately needed cost savings. We offer both the products and the expertise to analyze and recommend the right solutions.

-

Sustainability

Earth Day

4/22

In June of 2021, The U.S. Plastics Pact announced an aggressive national strategy to ensure all plastic packaging will be reusable, recyclable, or compostable by 2025. “The roadmap is designed to help U.S. industry leaders act on the significant, systemwide change needed to realize a circular economy for plastics by 2025…if we choose to do nothing, the visions of a circular economy across the U.S. will give way to the status quo,” said Emily Tipaldo, Executive Director, The U.S. Plastics Pact.

For a product or material to be truly described as sustainable, it must meet the Three Pillars of Sustainability: environmentally, economically, and socially.

An environmental profile is defined as “A method of identifying and assessing the environmental effects associated with building materials.” Only 4% of the world’s oil production is used for plastics and much less energy is used to produce it compared to other materials. They also make a large contribution to environmental sustainability through their potential for energy savings, energy recovery, and recyclability. Whether as a car bumper or a bottle, when the “use” phase of plastic material is up, we can recycle these items. However, if it is not environmentally beneficial, the calorific value of plastic, aka the energy contained in fuel which is measured by the heat produced during combustion, can be recovered through the energy from waste incineration, providing a source of home-grown power.

Despite conflict regarding various plastic types, and the additives used to give them properties that allow for many useful benefits, the industry continues to be strong across the nation. Over the past two decades, plastics have not only contributed to the economy through manufacturing and new applications, but it has also contributed through recycling.

Plastics are also socially sustainable. The plastics industry is one of the largest manufacturing industries in the U.S. It generates $451 billion per year and employs 1.5 million. More and more, we rely on new and evolving plastic materials for our day-to-day lives, especially when it comes to our safety. Plastics in cars, for example, reduce weight and allow for the addition of safety features such as airbags. Modern plastic packaging captures reduced-oxygen air mixtures and controls the exchange of oxygen and carbon dioxide… all helping to keep our food safer and fresher. Plastics are essential in modern-day healthcare and are used in surgery, healthcare products, pharmaceuticals, and medical packaging.

The impact plastics have made economically, socially, and environmentally has allowed them to solidify their impact and importance across the globe. The conversation on sustainability is one that does not end here. There are countless things we can do in our communities and homes to help promote sustainable practices in plastics. The simplest way is to recycle. Set up recycling bins in your homes and offices, somewhere universal for everyone (kitchens, lunchrooms, etc.) We all play an important part in taking care of our planet to ensure its stability for generations to come.

Now, more than ever, at IMS we are dedicated to helping all our customers discover the best practices to conserve energy as well as time and money. We also encourage our employees to recycle with our in-house recycling unit which allows for the recycling of cardboard boxes and plastics. Any unshipped catalogs are sent to a local paper company to be recycled as well. Not only is this an important business principle, but it is also a fundamental moral responsibility.

-

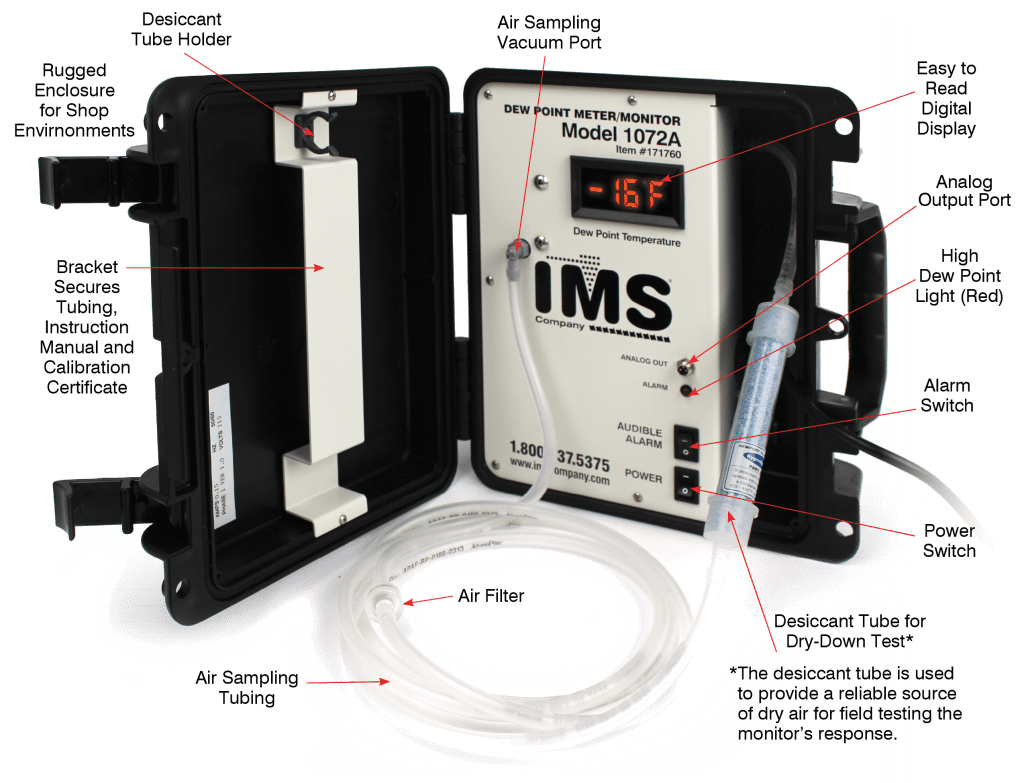

Dew Point Meter/Monitor

Monitor And Spot Check The Performance Of Your Desiccant Style Drying Equipment

Dew Point Range: -40°F to +30°F (-40°C to -1.1°C)

- Establish a repeatable, controlled drying process

- Alerts you to potential problems with desiccant style material dryers

- Verify the accuracy of your material dryers built-in Dew Point Meter (if equipped)

- Built-in Self Test

- Manufactured using NIST*-traceable equipment

- Available with current calibration certificate / Can be recalibrated

- Monitor case is compact, lockable, self-contained and portable

- Adjustable alarm set points and changeable temp. display (F to C)

*National Institute of Standards and Technology

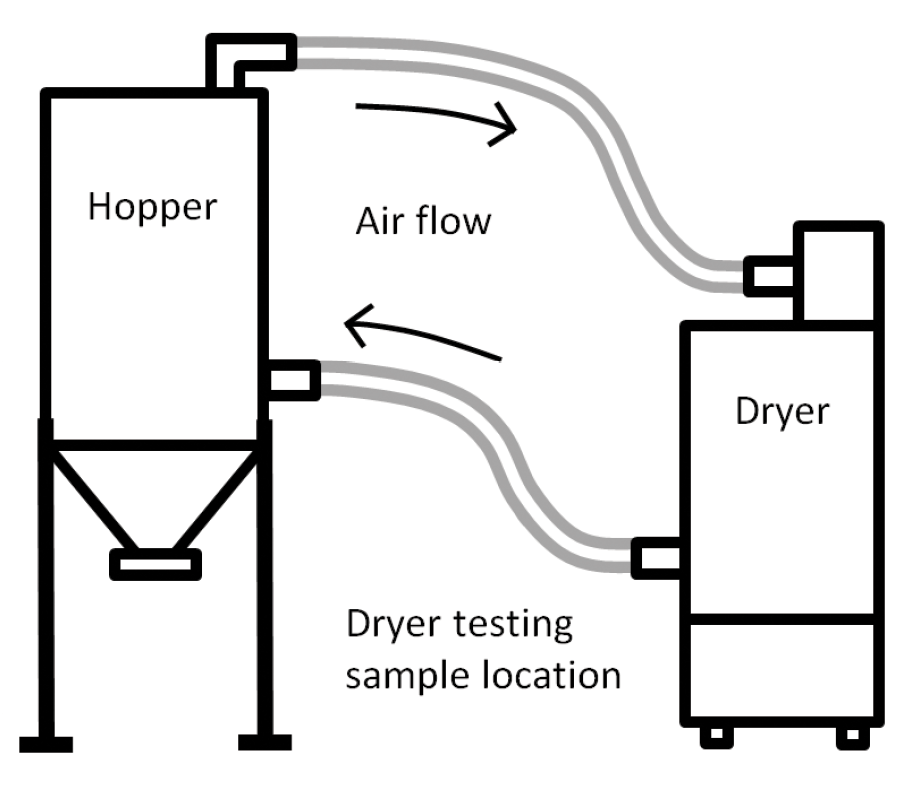

How They Work

The meter draws a dried-air sample from the dryer output. The sample’s moisture level affects the electrical resistance of the meter’s hygrosensor. By reading that resistance, the meter can give the Dew Point Temperature — the drier the air, the lower the dew point.

Specifications

The sampling tubing supplied with the monitor can tolerate temperatures up to 275˚F (135˚C). Higher process air temperatures can be cooled to a safe level by sampling through a few feet of ¼” copper tubing.

- Sample Air Temperature Limits: Up to 500°F

- Dew Point Range: -40° to +30°F (-40° to -1.1°C)

- Typical Accuracy: ±3°F (1.7°C)

- Alarm Set Point: -10°F (-23˚C)

- Sensor Item #: 172054

- Analog Output Scaling: -40°F to +70°F (-4˚C to -9˚C)

- Power Requirements: 115VAC 50/60HZ / 0.15A max

(230VAC optional) - Dimensions: 10.75” x 9.75” x 4.75”

- Shipping Weight: 7 lbs.