IMS Company

A trusted partner for the plastics processing industry, offering a wide range of high-quality, process improving products at competitive prices. We are a diversified distributor specializing in supplies, components, auxiliary machinery, and equipment. With 75 years of industry experience, our stocked warehouse ensures fast, reliable delivery, helping you maintain peak production efficiency. Whether you need innovative products, expert support, or tailored solutions, IMS Company has the expertise and resources to keep your operations running smoothly. Visit us at imscompany.com for more!

For 75 years, one thing has never changed at IMS — our single-minded focus on providing products and services designed to help your shop increase efficiency and ramp up productivity.

Check out IMS on YouTube!

Blogs

July 28, 2025 – Why Keiba Gate Cutters Excel in Precision Cutting

June 3, 2025 – Sizing a Desiccant Dryer for Plastic Injection Molding

May 7, 2025 – Mold Cleaners

January 7, 2025 – Time to Purge

November 4, 2024 – Plant Shutdown

October 22, 2024 – Prepare Your Shop for Winter

September 11, 2024 – New Injection Press Setup

August 26, 2024 – D-limonene

August 14, 2024 – Mold Rust Prevention

July 9, 2024 – Mold Cleaner vs. Mold Release

March 25, 2024 – Part Diverting Systems

March 13, 2024 – Chill Out

February 22, 2024 – Why is Moisture a Problem

February 19, 2024 – What is a Vacuum Loader

February 5, 2024 – Injection Molding Nozzle Tips

January 29, 2024 – Metal Separation

May 30, 2023 – Benefits of Insulation

April 22, 2023 – Sustainability

March 20, 2023 – Dew Point Meter/Monitor

March 2, 2023 – IMS Lime Buster

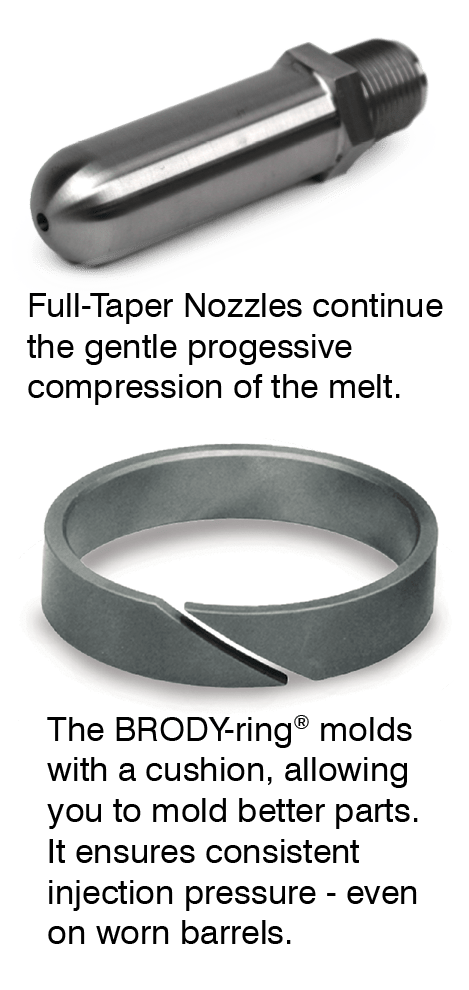

March 1, 2023 – IMS Brody Ring

January 30, 2023 – Clean Room Manufacturing

January 1, 2023 – Heater Band Wiring

December 21, 2022 – IMS Select Drum Tumbler

December 8, 2022 – Plastic Granulators

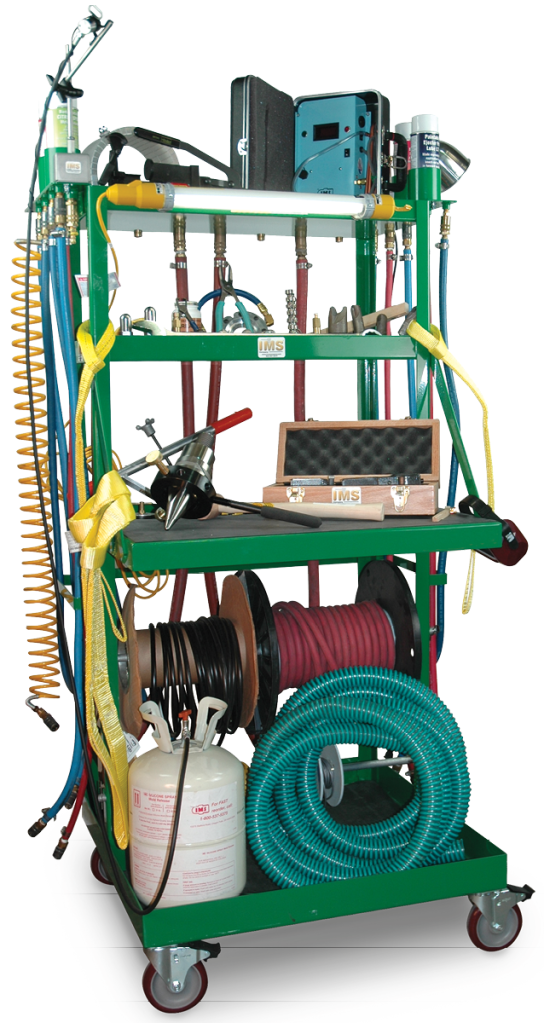

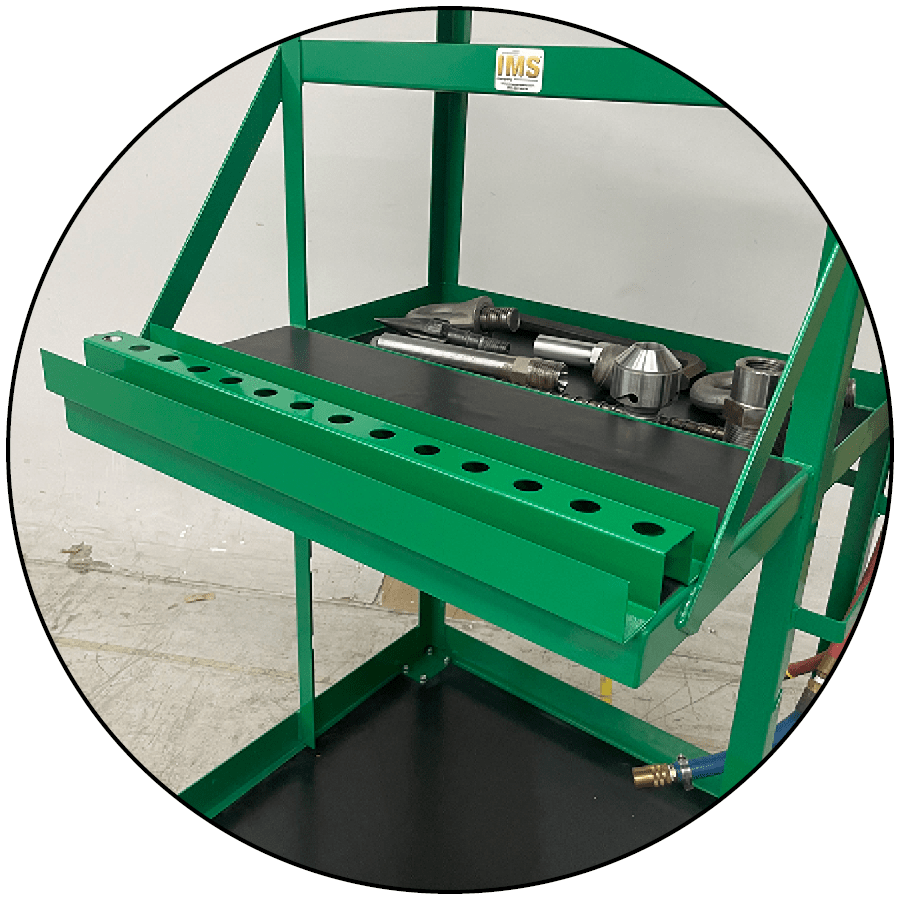

December 6, 2022 – Mold Setup Cart

November 28, 2022 – Eliminate Static and Dust

November 18, 2022 – Extending the Life of Your Heater Band

November 2, 2022 – How to Set Barrel Zone Temps

September 9, 2022 – The Benefits of Extruder Screens

August 24, 2022 – Calculating Heat Load for a Circuit

August 17, 2022 – Purgex Purging Compounds

August 12, 2022 – Air Wipe

August 11, 2022 – IMS Custom Projects

August 4, 2022 – New Shini Hopper Loader Systems

July 21, 2022 – Quick Change Fittings – Thread Profile Sizing

July 19, 2022 – IMS Custom Project

June 20, 2022 – Safety First

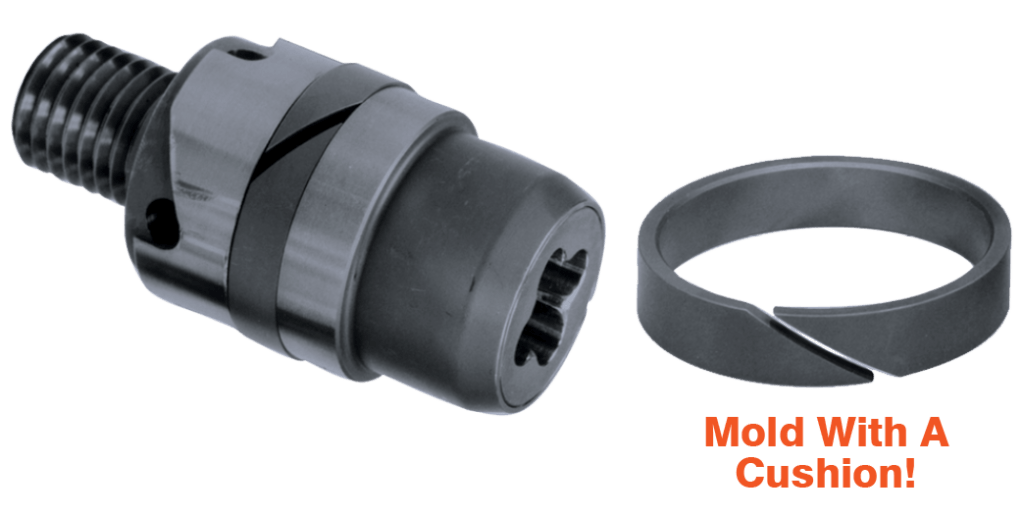

June 15, 2022 – IMS Screw Tip Brody Ring

June 15, 2022 – Screw Material Guidelines

June 15, 2022 – Screw Tip Wear Issues

June 15, 2022 – Essential Barrel Information

June 9, 2022 – Mold Safety Checklist

June 2, 2022 – Why Choose High Quality Desiccant?

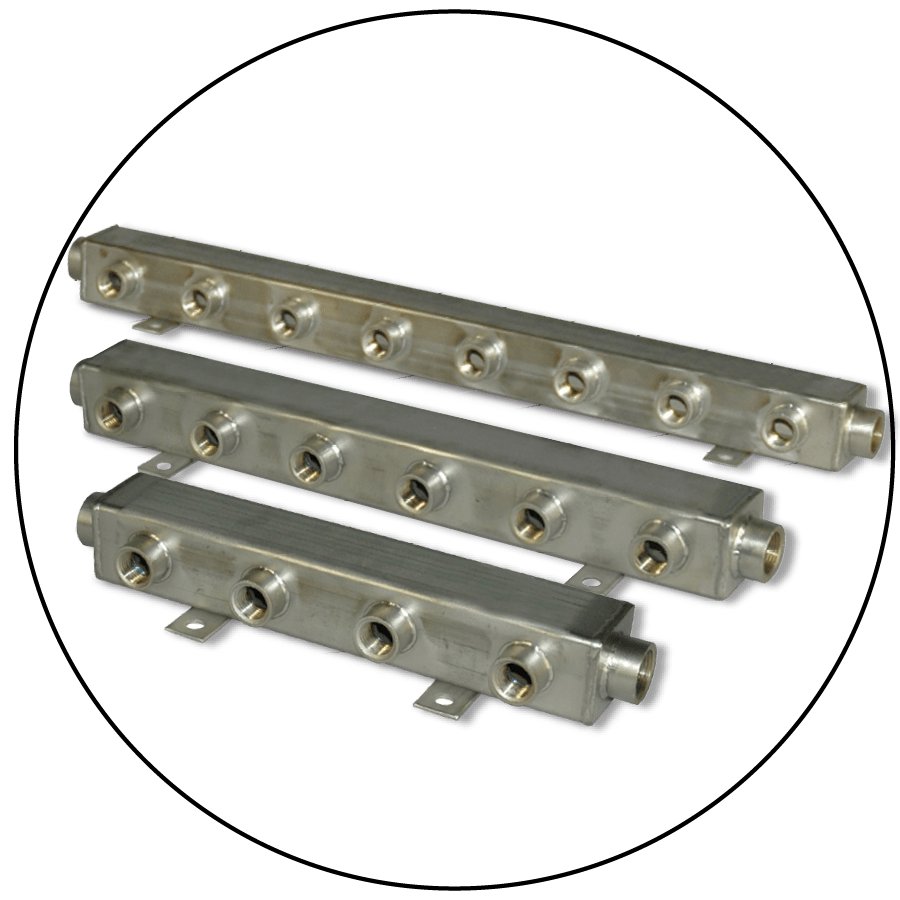

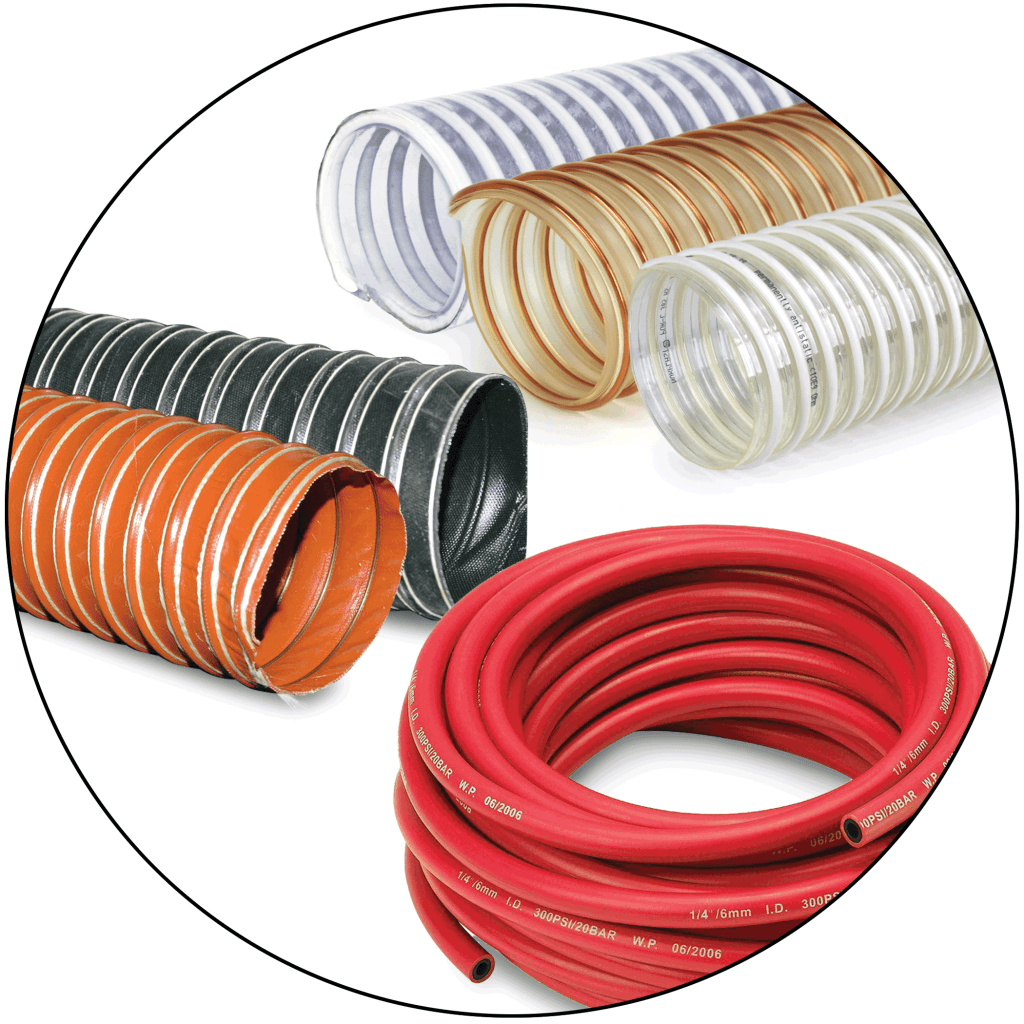

May 26, 2022 – Circulators 101

May 19, 2022 – Sizing a Chiller

April 25, 2022 – Mold Temperature Control Product Selection

April 19, 2022 – Selecting the Right Gate Cutter For Your Job

April 12, 2022 – Barrel Insulation Blankets

April 4, 2022 – Quick Mold Change

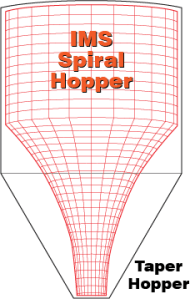

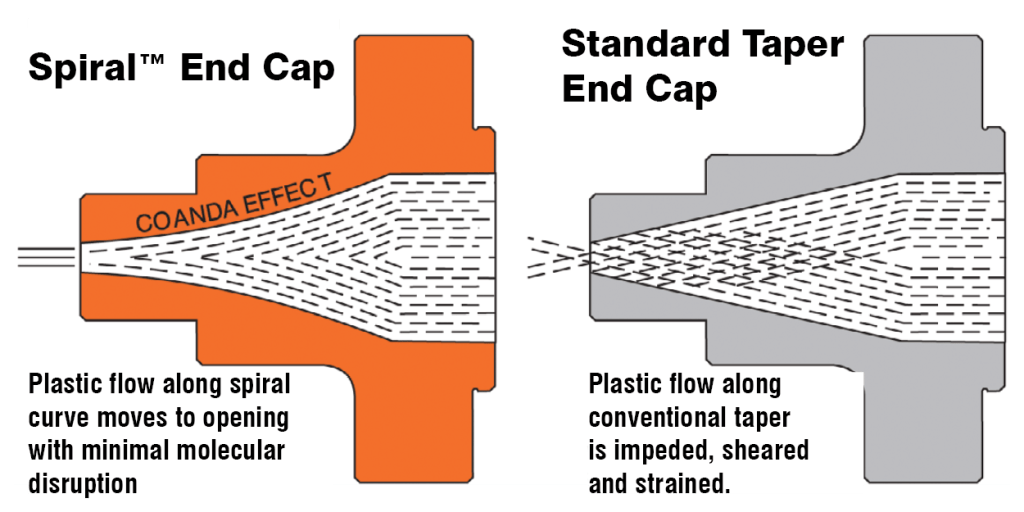

March 14, 2022 – Spiral Technology

February 17, 2022 – Screw Tips

-

Circulators 101

March 6, 2024

Circulators (Thermolators, Temperature Controllers) are essential components in injection molding processes, primarily utilized for controlling the temperature of molds so that as the part cools after injection, it maintains dimension, shape and structure – ensuring consistent quality and efficiency. Controlling the mold temperature is critical to good parts. You can get good melt flow, and the cavity can fill quickly and fully, but if the part is not cooled properly then a good melt flow means nothing.

Circulators need to be compatible with the injection molding machinery and seamlessly integrated into the overall manufacturing setup for efficient operation. Regular maintenance and monitoring of circulators are essential to ensure they continue to function optimally, thereby avoiding downtime and production delays. In advanced setups, circulators may be integrated into the overall automation system of the injection molding process, allowing for real-time monitoring and control of temperature parameters.

Here’s how circulators are typically used in injection molding:

- Cooling: Cools the molds after each cycle. Rapid cooling is essential for improving cycle times and overall productivity.

- Heating: In some cases, circulators may also be used for heating the molds to specific temperatures.

- Thermal Stability: Ensure thermal stability throughout the injection molding process, which is crucial for preventing defects and maintaining part quality.

- Energy Efficiency: Modern circulators often come with energy-saving features to optimize energy consumption during the temperature control process, contributing to cost-effectiveness and sustainability.

- Process Optimization: By precisely controlling the temperature of molds, circulators play a vital role in optimizing the process for different materials and product specifications.

Overall, circulators play a critical role in maintaining temperature control and ensuring the quality, efficiency, and reliability of injection molding operations. Their proper selection, installation, and maintenance are essential considerations for any injection molding facility.

IMS offers several options for temperature control needs: Circulators, Mold Temperature Controllers

You May Also Need:

Heat Transfer Fluids

A Quick Comparison Of Heat Transfer Mediums

• Water — Limited use range: 32° to 212°F. Encourages corrosion.

• Uninhibited Glycols — Allow temperatures to 250°F, but 2½ times more corrosive than water, if not neutralized.

• Automotive antifreeze — Contains corrosion inhibitors, but can foul heat transfer surfaces in less turbulent systems.

• UG-10 Ethylene Glycol — Low silicate formula provides good corrosion protection at a relatively low price.

• EG-17 Ethylene Glycol — Industrial inhibitors coat surfaces and impact pH for maximum corrosion protection.

• Pro-17 Inhibited Propylene Glycol — Non-Toxic Heat Transfer Fluid With Maximum Protection Against Acidity and Corrosion.

• PG-1 Hi-Heat Transfer Fluid — The Ultimate, Non-Toxic Fluid For Non-Pressurized Heating To 600°F.

• FF-1 Oil System Flushing Fluid — Improves heat transfer for faster cycles.

• PSC Plus Oil System Cleaner — Maximizes heat transfer for more parts and increased quality.In addition, how efficiently any of the above units work is directly tied to how clean your mold passages are. Any buildup of scale can affect the transfer of heat. The passages need to be checked and maintained regularly. To help with that, IMS offers the Limebuster which helps remove the scale buildup in mold passages. Just 1/64″ of scale can reduce the heat transfer rate up to 40%. Using an acid/water mixture, the fluid is circulated by a low pressure pump. The fluid helps dissolve the scale slowly so good heat transfer can return. This type of unit also is used to clean heat exchangers.

While the above is basic in its presentation, the message is clear; IMS understands and can help. IMS has the expertise and the equipment to help maintain and even improve your process. Good parts and reduced scrap means you make money.

That is what we are here to help with. Call IMS Today for all your Injection Molding needs.

-

IMS Lime Buster

The Original Water System Descaler and Lime Eliminator!

3/2/2023

Use as mold maintenance or when a mold is removed from storage.

Descaling mold water passages (channels within the mold through which coolant flows to control the temperature during the molding process) is an essential aspect of mold maintenance in injection molding.

Over time, these passages can accumulate scale deposits, which are typically a buildup of minerals, rust, or other contaminants from the water used in the cooling system. Mineral deposits can shrink the functional size of the water passages, causing a drop in flow – and therefore a drop in the ability of the mold to cool the plastic parts quickly.

To descale passages effectively, various methods such as chemical agents, mechanical cleaning, or ultrasonic cleaning may be employed, depending on the severity of the scale buildup and the material composition of the mold. It’s essential to follow the manufacturer’s recommendations and best practices to ensure thorough cleaning without damaging the mold surfaces. Regular descaling as part of a comprehensive mold maintenance program helps optimize mold performance and prolong its lifespan.

Plastic Injection Mold Process — Dissolve and Flush Away Contaminants from Mold Passages, Water Lines and

Heat ExchangersWhy descale mold water passages?

- Maintaining Cooling Efficiency: Scale deposits can reduce the efficiency of the cooling system by obstructing the flow of coolant through the water passages. This can lead to uneven cooling of the mold, resulting in variations in part quality, increased cycle times, and potentially even thermal stress on the mold.

- Preventing Mold Damage: Severe scale buildup can lead to blockages in the water passages, causing localized overheating of the mold. This can result in thermal fatigue, warping, or even cracking of the mold components, compromising their structural integrity and lifespan.

- Preventing Corrosion: Scale deposits can create an environment conducive to corrosion within the water passages. Corrosion can weaken the mold material, leading to premature failure and costly repairs or replacements.

- Maintaining Part Quality: Descaling the water passages helps ensure that the mold maintains the desired temperature profile throughout the molding process, resulting in uniform part dimensions, reduced defects, and improved surface finish.

- Minimizing Downtime: Regular descaling of mold water passages as part of routine maintenance helps prevent unexpected issues such as mold overheating or cooling system failures, minimizing unplanned downtime and production disruptions.

Biodegradable Descalers

Any product that can dissolve those deposits must contain acid. An acid solution will re-dissolve the mineral deposits and flush them away. Acid is the only thing that can cause this re-dissolution.

“Biodegradable” descalers sounds safe, but are still approximately 9% hydrochloric acid – very strong. The user normally mixes a biodegradable descaler 50/50 with water so you are at 4.5% of a very strong acid when used. Biodegradable descalers are mainly water, yet cost almost as much an acid. A larger amount of biodegradable descaler must be used to reach an appropriate strength. The ratio of cost to descaling ability is very poor for biodegradable descalers.

Biodegradable descalers are formulated to clean potable water systems on ships and sailing vessels. They include chemicals that are designed to remove biological agents like slime, mildew, and mud. That is an issue that most molders don’t face most of the time. If you have a yacht, definitely use the biodegradable descaler. If you have molds, use an acid.

Why bother with a neutralizer?

Acid must be neutralized before disposal as waste water. Too much acid will damage the water treatment system.

Why use a Lime Buster from IMS?

IMS pioneered this equipment. We also have years of improvements and application support. DON’T BE FOOLED by premixed solutions and similar knock-off products that make the same claim. The Lime Buster is built for consistency and safety even in rugged conditions. This low-maintenance system is offered in two sizes, the Lime Buster III (11 gal.) and the Lime Buster XL (30 gal.). Designed with the user in mind, the Lime Buster’s success can be accredited to:

- High-flow low pressure CPVC Plastic Pump with Thermally Protected Continuous Duty Motor

- Easy-Pour Wide-Mouth Tank Fill and Drain

- Durable Welded Polypropylene Construction specifically molded to form a tight seal.

- Plastic Frame, Tank, Pump, Fittings and Hardware ensure corrosion resistance and long life

- Integral Grounded Switch Box

- Easy access ON/OFF Switch

- 5 Ft. Grounded Power Cord with Plug

- Quality All-Swivel Castor with Rubber Wheels

-

Clean Room Manufacturing

January 30, 2023

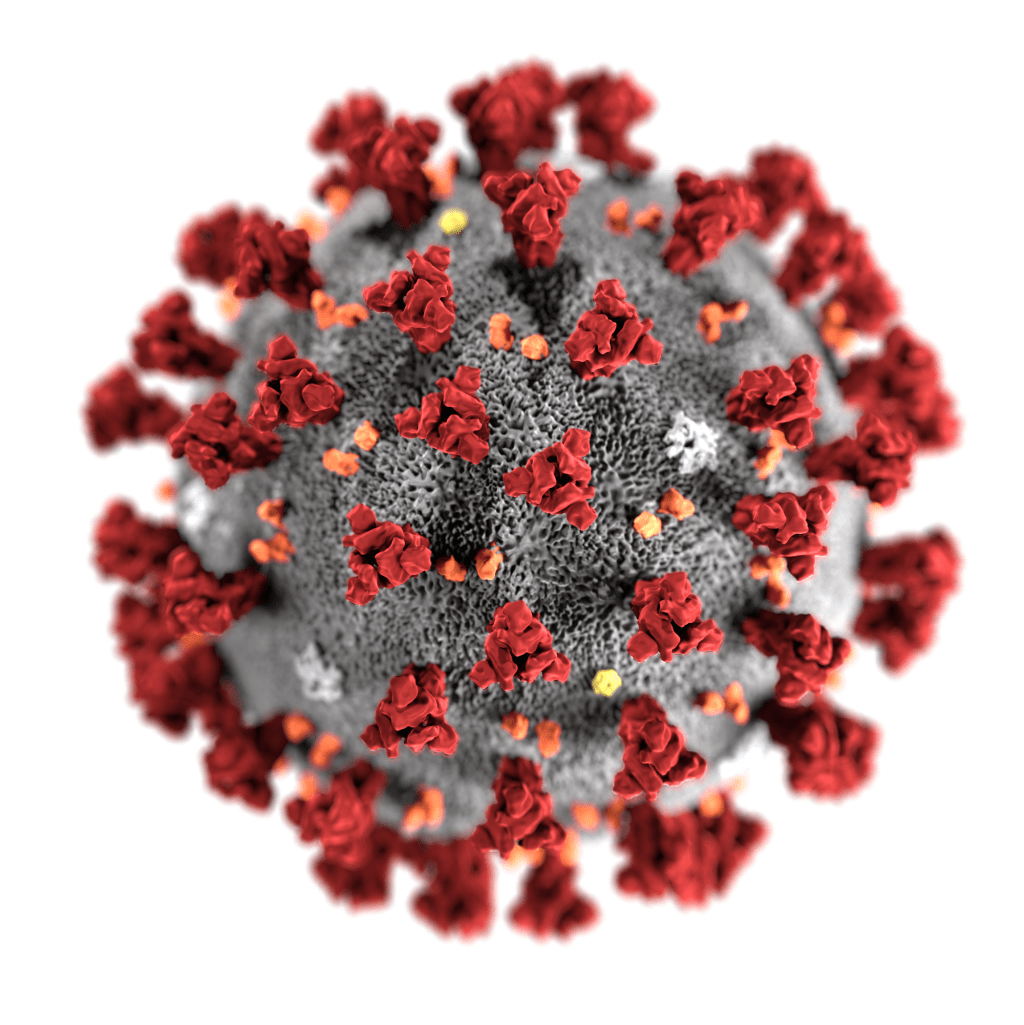

We all can remember where we were in March 2020. What began as a two week stay at home order turned into a global pandemic which left many of us wondering when we would return to work, school, and what life would look like post COVID-19. As we continue to develop our new normal, the medical and pharmaceutical industries are still on the front line developing their own post pandemic response.

Because of this, cleanrooms have solidified themselves as serving an integral part of the production process. A cleanroom is a controlled environment where pollutants like dust, airborne microbes, and aerosol particles are filtered out to provide the cleanest area possible. Cleanrooms can be classified into different levels of contamination depending on the amount of particles allowed in the space, per cubic meter and can also control variables like temperature, air flow, and humidity.

One of the many hurdles of designing cleanrooms is their ability to deal with air pollutants. That is why the need for high quality filtration units is key as they control airflow and halt airborne particles from entering. When designing your clean room, make sure to include carbon filters and non-filter purifiers.

Another issue to consider is the list of materials banned from use in a Clean Room. Stainless steel equipment is often used in cleanroom environments because it can meet strict hygiene requirements. This robust metal can also withstand the most rigorous cleaning processes. IMS is your source for products fit for a Clean Room Environment.

Providing training for all staff to ensure they are properly wearing the correct PPE is essential to preventing cleanroom contamination.

Working in a cleanroom goes far beyond cleanliness. Manufacturing in a clean room requires a high level of training and competency by personnel to maintain the environment’s standards and cleanliness. Be sure your team understands the environment and industry-specific concerns as operations require strict attention and procedures.While COVID-19 brought to light many gaps in our preparedness, the US has continued to be the leader of innovation in all levels of life science industries. IMS Company has helped science industries maintain their clean rooms for over 70 years. Let us be on the frontline with you for today’s challenges and beyond.

-

Heater Band Wiring

January 1, 2023

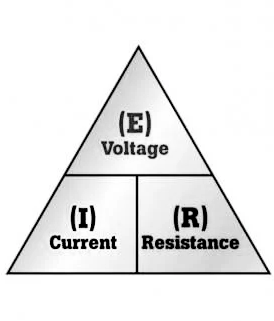

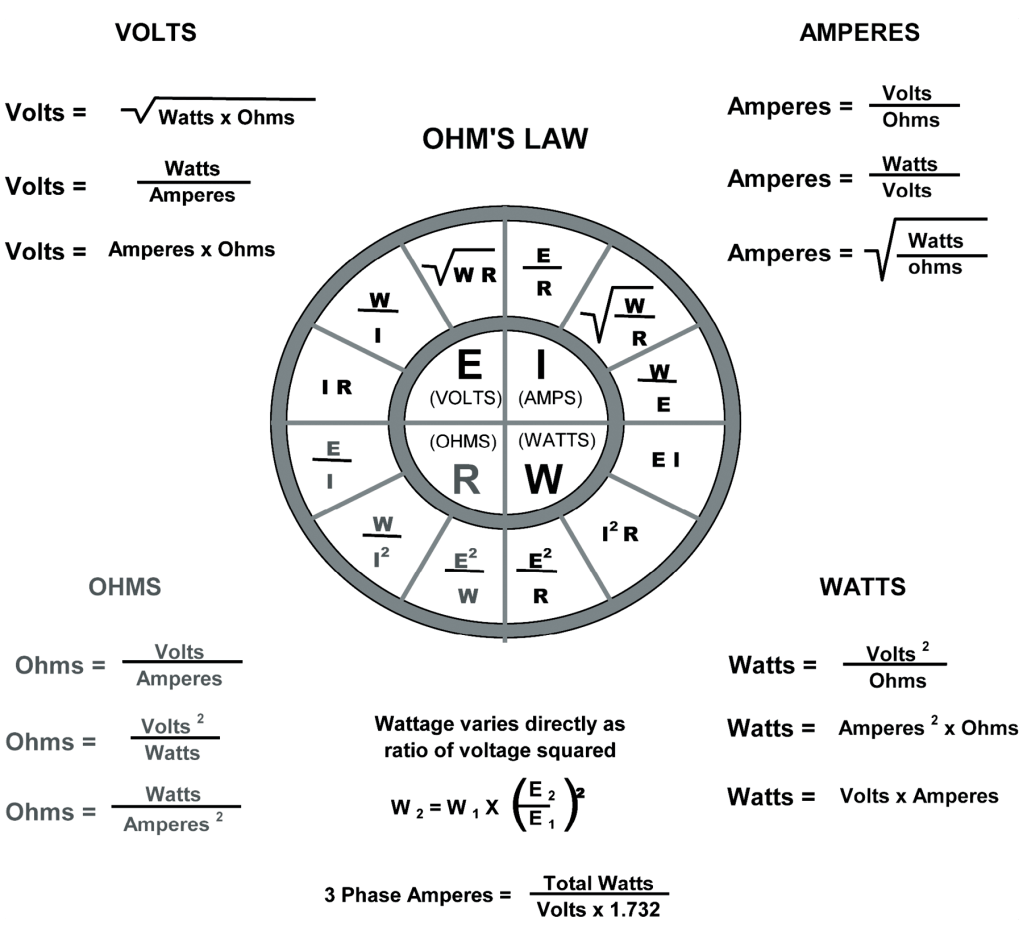

Ohm’s Law

In other instances another material may impede the flow of current, but still allow some though. In electrical circuits, these components are often called resistors. Yet other materials let virtually no current though and these materials are called insulators.

(Source: https://www.electronics-notes.com/)Variations of Ohm’s Law

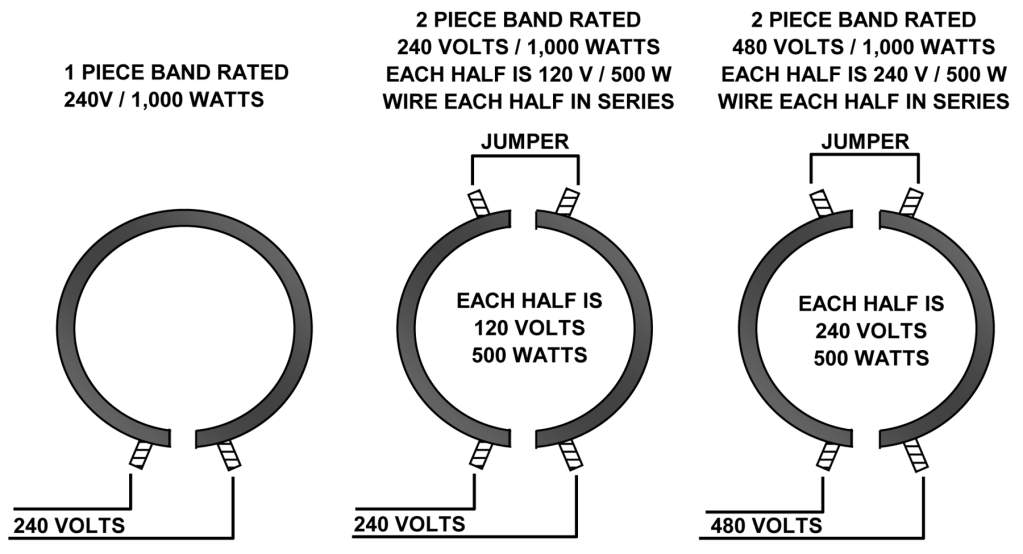

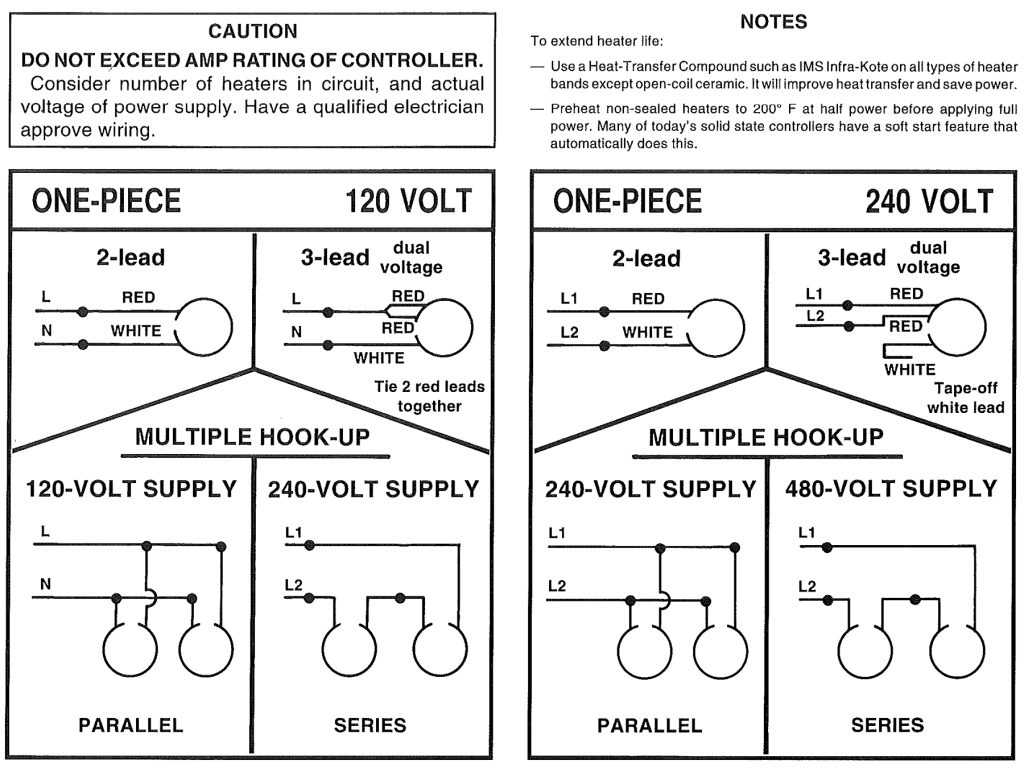

One Piece and Two Piece Bands:

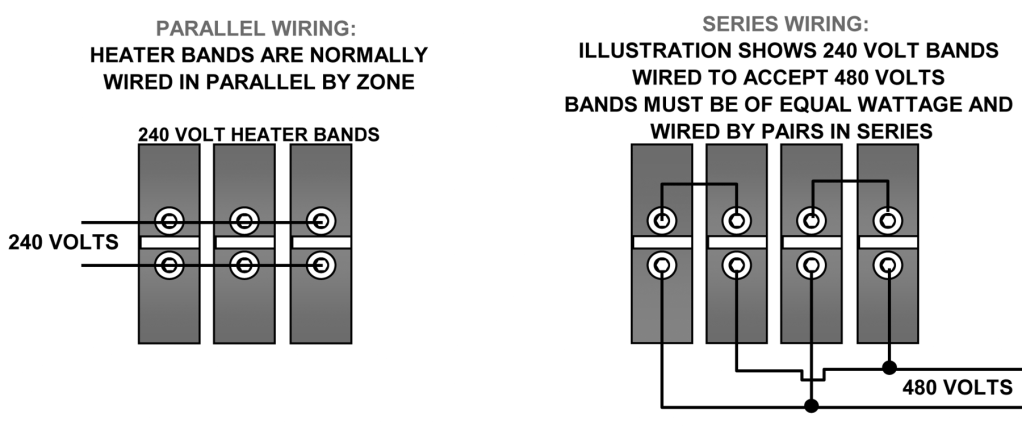

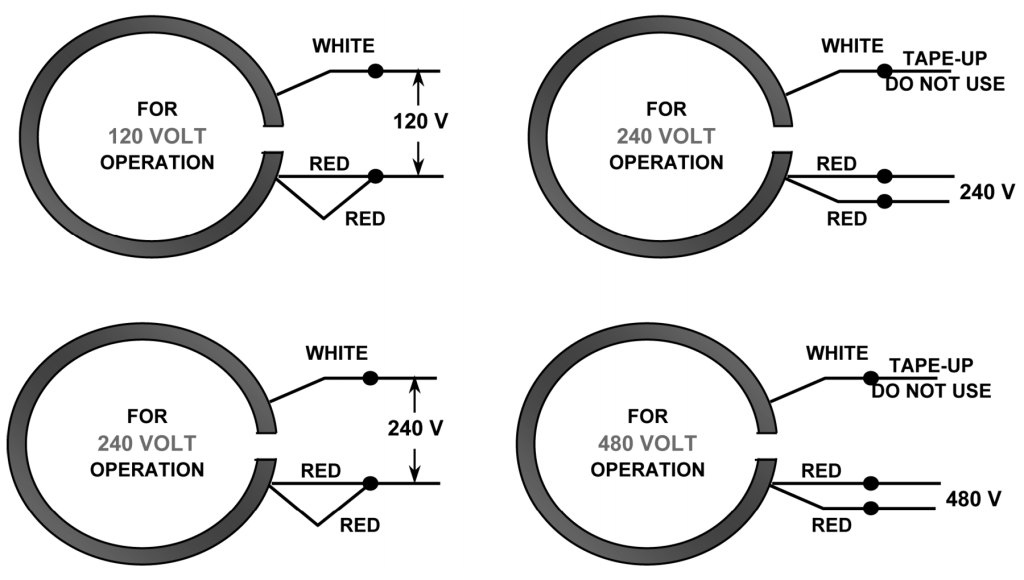

Parallel and Series Wiring

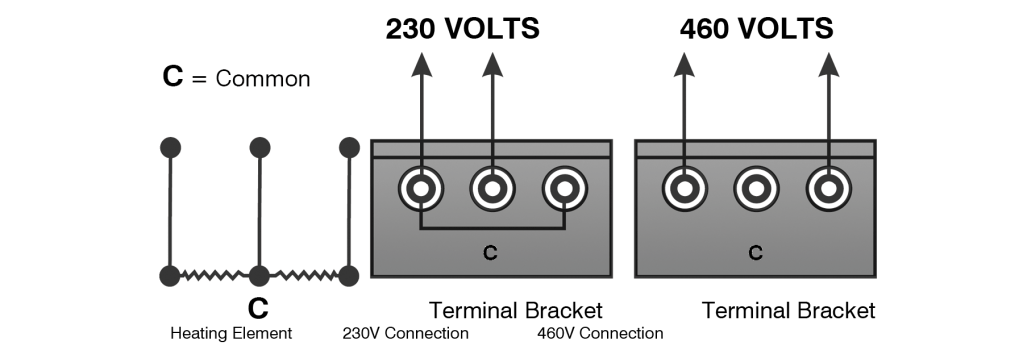

3 Post Terminal Wiring

Dual Voltage

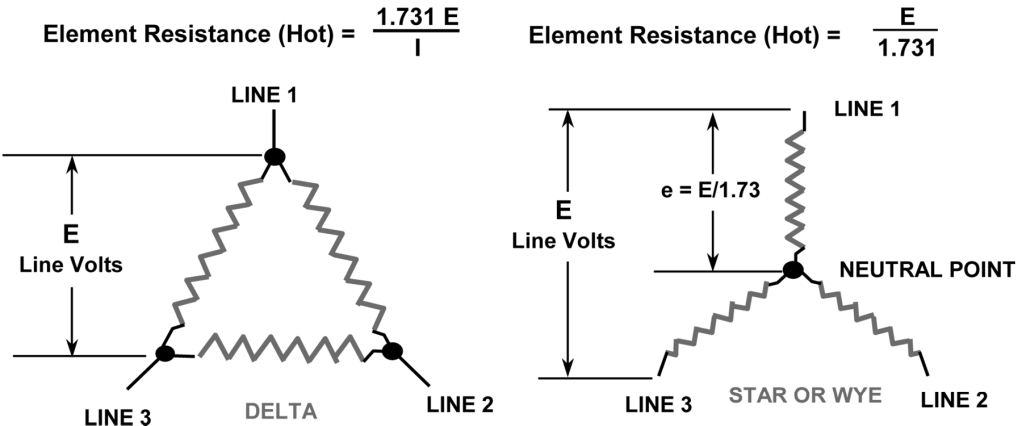

3 Phase

Wiring Instructions

Should You Connect Heaters

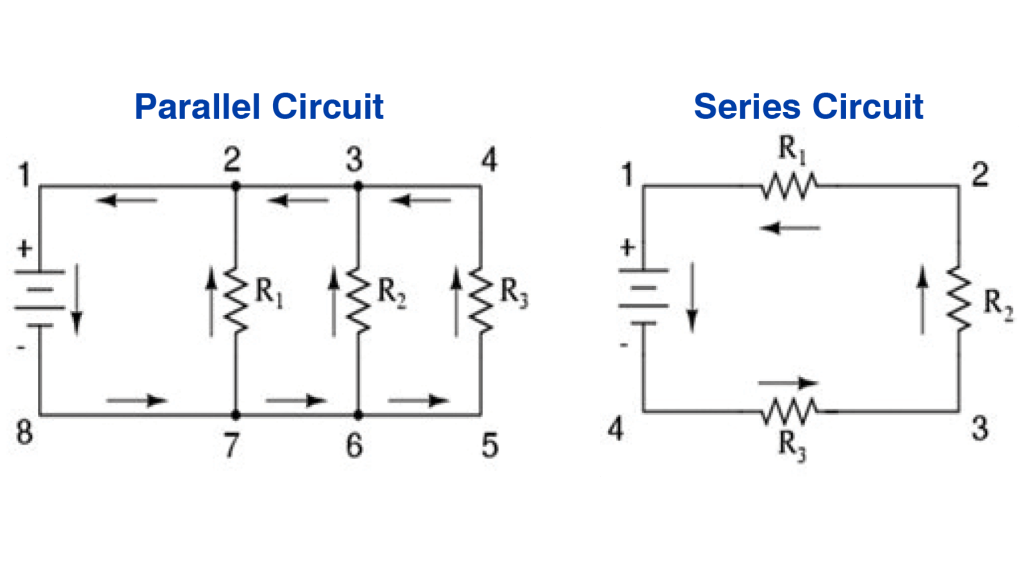

in a “Series Circuit”?This question arises when more than one heater is to be connected to electrical power.

– Usually any number of heaters can be connected in a “Parallel Circuit”.

– Usually only two heaters may be connected in a “Series Circuit” as it is much more complicated to do so.

The main disadvantage of a “Series Circuit” is that there is only one path in which the current can flow. Opening or breaking a Series Circuit at any point will cause the entire circuit to “open” or stop operating:- In a “Series Circuit” every heater must function properly for the entire circuit to operate. If any heater fails, all other heaters within that circuit will not receive power to operate, whereas in a

“Parallel Circuit” the failure of one heater will not affect the other heaters in that circuit. - If two heaters are connected in a “Series Circuit” the voltage of each heater must be the same and equal to “one half” of the total voltage available. Example: Let’s say you have two 240 volt heaters connected in series, therefore you must provide a 480 volt supply for the heaters to function properly.

- The wattage of each heater is a “Series Circuit” must also be of the same value. If the wattage and voltage for each heater are not the same value the heaters will not split the voltage equally,

resulting in improper heating.

If you must wire heaters in “Series” the basic rule of thumb is that only two heaters are wired together, and those heaters must have the same voltage and wattage specifications.

- In a “Series Circuit” every heater must function properly for the entire circuit to operate. If any heater fails, all other heaters within that circuit will not receive power to operate, whereas in a

-

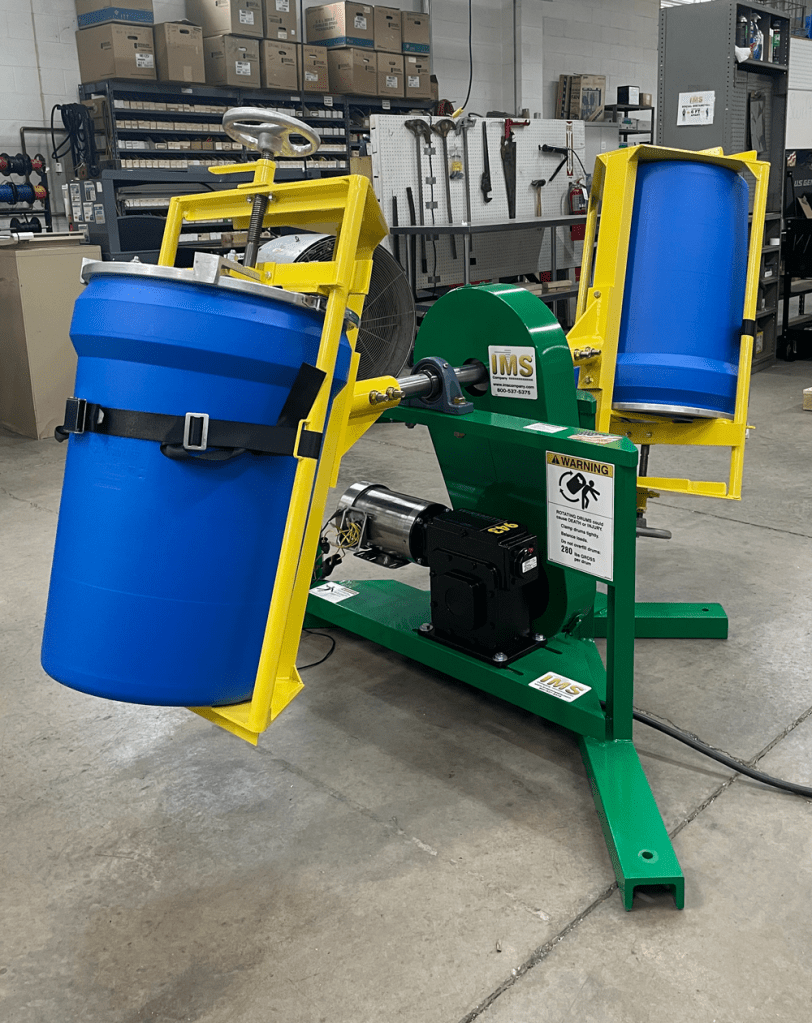

Drum Tumbler

An IMS Exclusive Product

Easily Blend Material While Saving Time, Labor and Money

December 21, 2022

IMS Select Drum Tumbler Video – Click to watch IMS’ Proven Performance

Optimum Mixing

- Exclusive 18 RPM and Drum Angle – provides the fastest, most complete mixing possible in the industry

Durable

- Solid steel frame – for longevity

- High torque drive belt – virtually adjustment free

- Built with components you can trust – Dayton motor

and Winsmith reducer

Double Drum Tumbler

- Smooth action, high torque belt drive

- Low-wear high ratio gear reducer

- Ample access to all components

Drum tumbler must have enclosure for operator safety — Contact IMS for enclosure options

Drum Tumbler Control Panel

Use this IMS Drum Tumbler Control Panel to operate tumblers from a safe distance.

Features Include:

- 60-minute Cycle Timer

- Run Selector Switch with Jog Function

- Amp Meter

- Alarm Horn

- 110 Volt Receptacle for Optional Alarm Light

- On/Off Switches for Alarm Horn and Alarm Light

-

Plastic Granulators

Granulators (sometimes referred to as grinders) are machines used to reduce scrap plastic parts or other plastic waste into a reusable form. This material – regrind – is sometimes put right back into the process to create the same parts. Other times it is reprocessed and re-pelletized for reuse.

Occasionally material is turned into a new and different product such as handbags, shoes, or anything else you can imagine.

Molders purchase granulators to reduce their carbon footprint, save money, and make a significant contribution to our environmental protection. In the past, waste plastics were generally disposed of by incineration and landfill, but these options can easily damage our ecological environment.

Regrind comes with its own set of challenges, however, because it is not at all uniform in shape and contains varying degrees of dust. The irregular shapes can affect material feed by bridging and clogging flow, and the dust can burn or cause other issues when processed.

The mechanics of a granulator include an open rotor mounted with powerful, rotating knives in a double scissor cut or V-shape. Stationary knives are fixed within the cutting chamber, and the rotor quickly spins while the rotor knives meet the stationary knives, slicing plastic until the pieces are small enough to pass through a screen filter.

You can minimize or entirely eliminate the possible negatives of regrind by choosing the correct grinder. The rotor style and blade configuration are critical because those two details determine the grind quality. Conventional style rotors, such as two and three-blade, are good in general applications, but depending on the material being cut and the configuration of the shape, a staggered cut rotor style may be preferable. Staggered blade configurations provide more cuts per revolution leading to a better quality of regrind, less part bounce in the cutting chamber, and a reduction in noise.

Terms to Know

Grinding is the process of downsizing items made of polypropylene (PP) to a size that can be used in plastic manufacturing.

Shredding refers to taking large components and shredding them down to random, smaller pieces which can be used for diverse applications.

The difference between grinding and shredding is grinding can make much smaller pieces due to its open rotor design. There is more air space for product cooling, which allows for easier processing of lighter materials.

Other factors to be considered in selecting a grinder include whether the scrap is:

- Manually or robotically fed (Hopper Selection)

- The hopper loader empties in the grinder catch pan or is manually emptied (Air Takeoff Port Required)

- You will be grinding at the press or in a central location

All of these details need to be considered when choosing a granulator.

Now that you understand how a granulator works, it’s time to select one which will work for you and your needs. IMS’s plastic granulators are extremely durable and can efficiently and quickly turn your plastic scrap into small, uniform flakes or regrind for recycling, allowing you to reuse every ounce of resin you have on hand.

If at any point in the process, if you’re not sure which of our granulator models is right for you, let IMS guide you along the way. IMS offers free grind tests to ensure you get the correct granulator for your plastic parts with ease. We will help examine all of the details and get the right unit for your need. That’s what we do best.

With over 70 years of experience, IMS Company is a trusted source of supplies, components, auxiliary machinery, and equipment.

How about giving us a try?

-

Eliminate Static and Dust!

November 28, 2022

When the air is dry, passing objects strip electrons from each other and develop a static charge. It can cause shocks up to 10,000 volts in people – painful, but not lethal. In plastics production, static can be lethal – to profits. Parts can jam up and dust attraction can ruin the product appearance.

IMS has a number of static solutions for your shop. The COBRA™ Air Gun removes the static charge and dust at the same time. The Ion Air Gun effectively removes the static charge that causes the attraction of dust, plastic particles, and fines as well as eliminating static electricity shocks. In addition to cleaning the finished product, these are great to clean molds, mixers, hoppers, grinders, storage containers, and loaders.

The COBRA™ breaks the static-electric bond between the metal and the dust and fines, then easily blows them away. At a normal line pressure of 80 PSI, the air gun’s high-volume stream of ionized air can drop an object’s voltage from 5,000 volts to 500 volts in 0.4 seconds at a distance of 3”.

To minimize air consumption, the COBRA™ uses airflow amplification to induce surrounding room air through the gun at a 3:1 ratio.

Here Is How It Works

Compressed air is released into the barrel of the gun (1) inducing a high-volume flow of surrounding air (2) to pass through it. The shockless emitter point (3) ionizes the entire airstream. The result is a high-volume flow of ionized air (4) capable of neutralizing high static charges in fractions of a second.

The COBRA™ Air Gun is lightweight and includes a hanger hook for easy storage. The 20-foot power cable is highly flexible and designed for rugged industrial use. An ergonomic grip allows hours of continuous use without fatigue.

Other advantages include:

- Strong blowoff force and flow

- Shockless, non-radioactive

- Meets OSHA pressure and noise level requirements

CAUTION: Wear proper safety equipment and follow safety procedures when using compressed air guns.

The Ion Air Gun gives you the benefits of rapid static decay along with low compressed air consumption. Surrounding room air is induced through the gun at a ratio of 5:1, minimizing compressed air use and maximizing airflow. The force can be adjusted from a “blast” to a “breeze”.

At a normal line pressure of 80 PSIG, the high-volume stream of ionized air is capable of neutralizing a 5,000 volt charge in 0.18 seconds! That’s incredibly fast!

The Ion Air Gun incorporates a High-Velocity Air Jet and electrically energized emitter point. A small amount of compressed air is injected into the barrel of the gun (1) inducing a high-volume flow of surrounding air (2) to pass through it. The emitter point (shockless) at the discharge end of the gun (3) ionizes the entire airstream. The result is a high-volume flow of ionized air (4) capable of neutralizing high static charges in fractions of a second. An optional filter and regulator cleans the compressed air and allows infinite adjustment of airflow and velocity.

The Ion Air Gun is quiet, lightweight and features a hanger hook for easy storage. The 10 foot shielded power cable is extremely flexible, designed for rugged industrial use. A comfortable grip and hand position allows hours of continuous use without fatigue.

Other advantages include:

- Strong blowoff force and flow

- Quiet (less than 80 dBA)

- Shockless, non-radioactive

- Meets OSHA pressure and noise level requirements

- Attractively priced

If you need help with a static problem, contact our Technical Support Hotline at 1-866-467-9001. IMS has a complete line of static eliminators and will be glad to help you select the appropriate model for your application.

-

Breaking the Mold Forum Follow Up

November 23, 2022

Finding Your Voice

This past weekend, I joined some of the industry’s top leadership professionals in Nashville at Women Breaking the Mold Networking Forum. Hundreds of women of various backgrounds and ages gathered with the same vision: to make the industrial sector a safe and promising place for women to grow their careers.

The first day was filled with anticipation. Walking in, my head was flooded with the thoughts that greet so many women when they are faced with a challenge. Will people like me? Do I look okay? Am I really qualified to be here? Just as quickly as it came, those worries and fears washed away as the first presentation began.

Our first speaker, Teresa Schell President/Owner of Vive Marketing, started her presentation with a brief introduction on what lead her to this conference. Her story deeply resonated with me as she touched on themes in her life that completely paralleled my own. From growing up in a lower-income family to trying to heal someone you love through the battle of addiction. Teresa made me feel that I was not alone and that I had the power within myself to create the life I know is meant for me. I felt as though I was looking at a future version of myself, someone who at times, when we are in the middle of our own confusion and storm, cannot see.

In between sessions, we had the opportunity to introduce ourselves to our group. We touched on professional and personal accomplishments, as

well as the struggles women have faced in trying to reach those milestones.

I will never forget a personal conversation with Dr. Jasmeet Kaur, Senior Sustainability Manager of The Coca-Company. We discussed the challenges and reality of what it takes for women to climb the corporate ladder, the sacrifices it takes to get there, and the importance of the people in our lives seeing us happy and fulfilled in something we work so hard to accomplish.

The influence of women in the workforce is more than just a seat at the table. In our discussion with Anoosheh Oskouian President & CEO of Ship & Shore Environmental, Inc. we learned the necessity to advocate for the less fortunate women in the world who may never have the opportunities we do. Everyone must do their part and be a voice for the voiceless who may never have the chance to be heard.

Often, women find themselves put in a box. No matter the size, it’s up to us to fight our way out. Women are put in positions of power because we are both creative and analytical beings, with ambitions to take our companies as far as they can go.

Women Breaking the Mold taught me how to be the voice of women around the world who are pursuing their dreams, as well as make sure to take time for myself in order to accomplish my goals. It is a reminder for us that self-care is not selfish, even though at times it feels we may not be taken seriously as we juggle prioritizing family, health, and career. The vast majority of women are STILL the primary caregivers to their children; they shop, cook, and clean, as well as have full-time, fulfilling careers. There will always be times when personal care takes precedence over professional responsibility, and that’s OK. It is up to womankind to demand that we are not seen as less, but as equal when professional opportunities arise.

To everyone I met at Women Breaking the Mold, I would like to express my sincere gratitude to you. Thank you for sharing with us your truth and confiding in your peers about the struggles and milestones you have faced along the way. I look forward to seeing you all again when we reunite in Scottsdale in 2023.