IMS Company

A trusted partner for the plastics processing industry, offering a wide range of high-quality, process improving products at competitive prices. We are a diversified distributor specializing in supplies, components, auxiliary machinery, and equipment. With 75 years of industry experience, our stocked warehouse ensures fast, reliable delivery, helping you maintain peak production efficiency. Whether you need innovative products, expert support, or tailored solutions, IMS Company has the expertise and resources to keep your operations running smoothly. Visit us at imscompany.com for more!

For 75 years, one thing has never changed at IMS — our single-minded focus on providing products and services designed to help your shop increase efficiency and ramp up productivity.

Check out IMS on YouTube!

Blogs

July 28, 2025 – Why Keiba Gate Cutters Excel in Precision Cutting

June 3, 2025 – Sizing a Desiccant Dryer for Plastic Injection Molding

May 7, 2025 – Mold Cleaners

January 7, 2025 – Time to Purge

November 4, 2024 – Plant Shutdown

October 22, 2024 – Prepare Your Shop for Winter

September 11, 2024 – New Injection Press Setup

August 26, 2024 – D-limonene

August 14, 2024 – Mold Rust Prevention

July 9, 2024 – Mold Cleaner vs. Mold Release

March 25, 2024 – Part Diverting Systems

March 13, 2024 – Chill Out

February 22, 2024 – Why is Moisture a Problem

February 19, 2024 – What is a Vacuum Loader

February 5, 2024 – Injection Molding Nozzle Tips

January 29, 2024 – Metal Separation

May 30, 2023 – Benefits of Insulation

April 22, 2023 – Sustainability

March 20, 2023 – Dew Point Meter/Monitor

March 2, 2023 – IMS Lime Buster

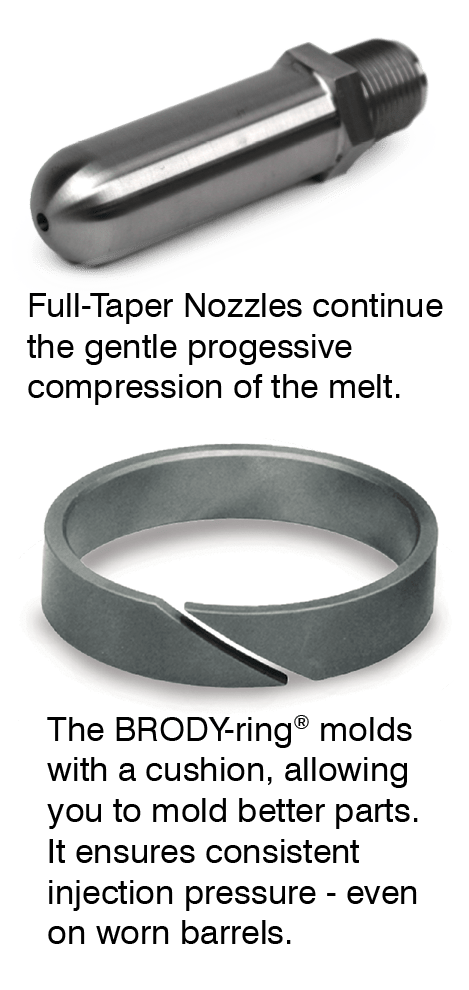

March 1, 2023 – IMS Brody Ring

January 30, 2023 – Clean Room Manufacturing

January 1, 2023 – Heater Band Wiring

December 21, 2022 – IMS Select Drum Tumbler

December 8, 2022 – Plastic Granulators

December 6, 2022 – Mold Setup Cart

November 28, 2022 – Eliminate Static and Dust

November 18, 2022 – Extending the Life of Your Heater Band

November 2, 2022 – How to Set Barrel Zone Temps

September 9, 2022 – The Benefits of Extruder Screens

August 24, 2022 – Calculating Heat Load for a Circuit

August 17, 2022 – Purgex Purging Compounds

August 12, 2022 – Air Wipe

August 11, 2022 – IMS Custom Projects

August 4, 2022 – New Shini Hopper Loader Systems

July 21, 2022 – Quick Change Fittings – Thread Profile Sizing

July 19, 2022 – IMS Custom Project

June 20, 2022 – Safety First

June 15, 2022 – IMS Screw Tip Brody Ring

June 15, 2022 – Screw Material Guidelines

June 15, 2022 – Screw Tip Wear Issues

June 15, 2022 – Essential Barrel Information

June 9, 2022 – Mold Safety Checklist

June 2, 2022 – Why Choose High Quality Desiccant?

May 26, 2022 – Circulators 101

May 19, 2022 – Sizing a Chiller

April 25, 2022 – Mold Temperature Control Product Selection

April 19, 2022 – Selecting the Right Gate Cutter For Your Job

April 12, 2022 – Barrel Insulation Blankets

April 4, 2022 – Quick Mold Change

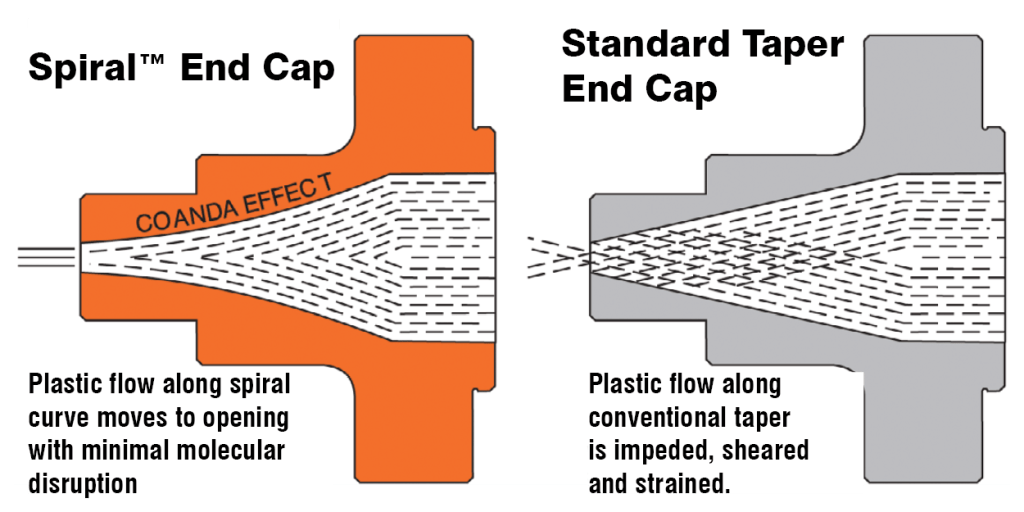

March 14, 2022 – Spiral Technology

February 17, 2022 – Screw Tips

-

Circulators 101

March 6, 2024

Circulators (Thermolators, Temperature Controllers) are essential components in injection molding processes, primarily utilized for controlling the temperature of molds so that as the part cools after injection, it maintains dimension, shape and structure – ensuring consistent quality and efficiency. Controlling the mold temperature is critical to good parts. You can get good melt flow, and the cavity can fill quickly and fully, but if the part is not cooled properly then a good melt flow means nothing.

Circulators need to be compatible with the injection molding machinery and seamlessly integrated into the overall manufacturing setup for efficient operation. Regular maintenance and monitoring of circulators are essential to ensure they continue to function optimally, thereby avoiding downtime and production delays. In advanced setups, circulators may be integrated into the overall automation system of the injection molding process, allowing for real-time monitoring and control of temperature parameters.

Here’s how circulators are typically used in injection molding:

- Cooling: Cools the molds after each cycle. Rapid cooling is essential for improving cycle times and overall productivity.

- Heating: In some cases, circulators may also be used for heating the molds to specific temperatures.

- Thermal Stability: Ensure thermal stability throughout the injection molding process, which is crucial for preventing defects and maintaining part quality.

- Energy Efficiency: Modern circulators often come with energy-saving features to optimize energy consumption during the temperature control process, contributing to cost-effectiveness and sustainability.

- Process Optimization: By precisely controlling the temperature of molds, circulators play a vital role in optimizing the process for different materials and product specifications.

Overall, circulators play a critical role in maintaining temperature control and ensuring the quality, efficiency, and reliability of injection molding operations. Their proper selection, installation, and maintenance are essential considerations for any injection molding facility.

IMS offers several options for temperature control needs: Circulators, Mold Temperature Controllers

You May Also Need:

Heat Transfer Fluids

A Quick Comparison Of Heat Transfer Mediums

• Water — Limited use range: 32° to 212°F. Encourages corrosion.

• Uninhibited Glycols — Allow temperatures to 250°F, but 2½ times more corrosive than water, if not neutralized.

• Automotive antifreeze — Contains corrosion inhibitors, but can foul heat transfer surfaces in less turbulent systems.

• UG-10 Ethylene Glycol — Low silicate formula provides good corrosion protection at a relatively low price.

• EG-17 Ethylene Glycol — Industrial inhibitors coat surfaces and impact pH for maximum corrosion protection.

• Pro-17 Inhibited Propylene Glycol — Non-Toxic Heat Transfer Fluid With Maximum Protection Against Acidity and Corrosion.

• PG-1 Hi-Heat Transfer Fluid — The Ultimate, Non-Toxic Fluid For Non-Pressurized Heating To 600°F.

• FF-1 Oil System Flushing Fluid — Improves heat transfer for faster cycles.

• PSC Plus Oil System Cleaner — Maximizes heat transfer for more parts and increased quality.In addition, how efficiently any of the above units work is directly tied to how clean your mold passages are. Any buildup of scale can affect the transfer of heat. The passages need to be checked and maintained regularly. To help with that, IMS offers the Limebuster which helps remove the scale buildup in mold passages. Just 1/64″ of scale can reduce the heat transfer rate up to 40%. Using an acid/water mixture, the fluid is circulated by a low pressure pump. The fluid helps dissolve the scale slowly so good heat transfer can return. This type of unit also is used to clean heat exchangers.

While the above is basic in its presentation, the message is clear; IMS understands and can help. IMS has the expertise and the equipment to help maintain and even improve your process. Good parts and reduced scrap means you make money.

That is what we are here to help with. Call IMS Today for all your Injection Molding needs.

-

Breaking The Mold

IMS Company is a trusted source molding supplies, components, auxiliary machinery, and equipment for the plastics processing industry. From the beginning, innovation has been at the heart of our business. We recognize an essential building block of innovation is providing our team members with opportunities to grow. So, when an employee presents us with a proposal to expand her knowledge, both of the industry and her professional skills, we couldn’t say no.Chloé Book started at IMS in February 2022 as the Marketing Assistant and quickly blossomed into the Marketing Specialist & Company Training Coordinator. She attended Kent State University with a focus in Communications, as well as Marketing and Public Relations. Her career goal was to work in an environment that was hands on in marketing and would allow her to make an impact not, only within the company, but in the industry, as well.

Her position at IMS allows her to focus on all things brand development, strategic planning, and team building. The focus of Chloé’s training courses ranges from professional development to company culture.

While familiarizing herself with IMS’s extensive product line, Chloé has taken the initiative to visit customers’ shops and see these products in action.

“It’s interesting to see the importance of every step in the process. Each step serves a different, specific purpose, but all have to work together. I try to apply this in my marketing strategy. Everyone on the team may serve a different role, but we are all working toward the same goal. It’s important I understand everyone’s process, function, and how we achieve success by supporting each step along the way.”

Looking to grow her knowledge of plastics, as well as the impact that women make in the industry, she is excited to attend:

The conference begins Monday, November 14, 2022 with a focus on “finding your voice”. Participants will attend various panel discussions, presentations, break-out sessions and networking opportunities. Chloé is excited to participate in this conference and develop her voice at IMS and in the plastic processing industry.

Throughout her professional efforts, she has discovered her passion for advocacy in the workplace, especially in male dominated industries.

“At conferences, you get to meet diverse people. Every contributor has unique perspectives to share. Conferences draw speakers and attendees who bring stories of courage and determination from all corners of the world. All the women featured in this event have made changes in remarkable ways, and they bring with them the mindsets and tools it took for them to do it.”

Well said Chloé. If you’re planning to attend Women Breaking the Mold in Nashville next month – let’s connect! We’re excited for Chloé to network and for IMS to continue our efforts to support women in the industry.

-

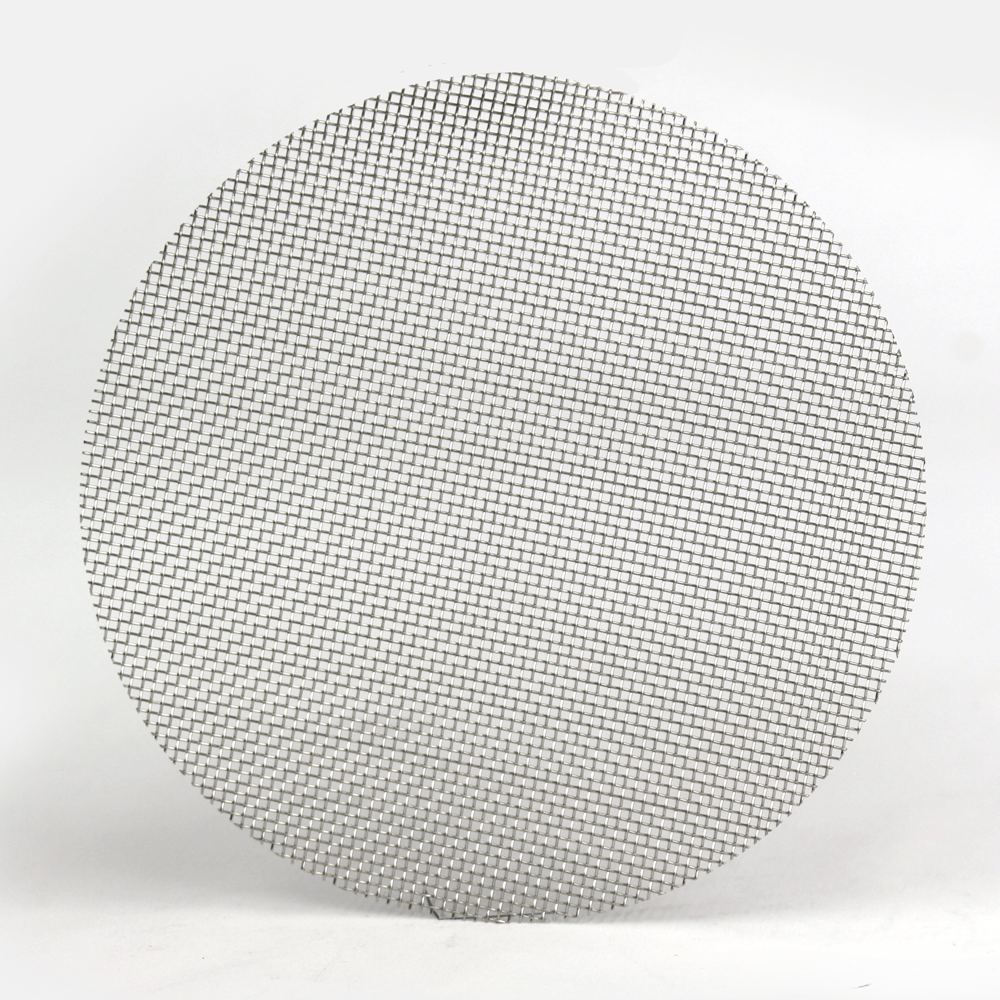

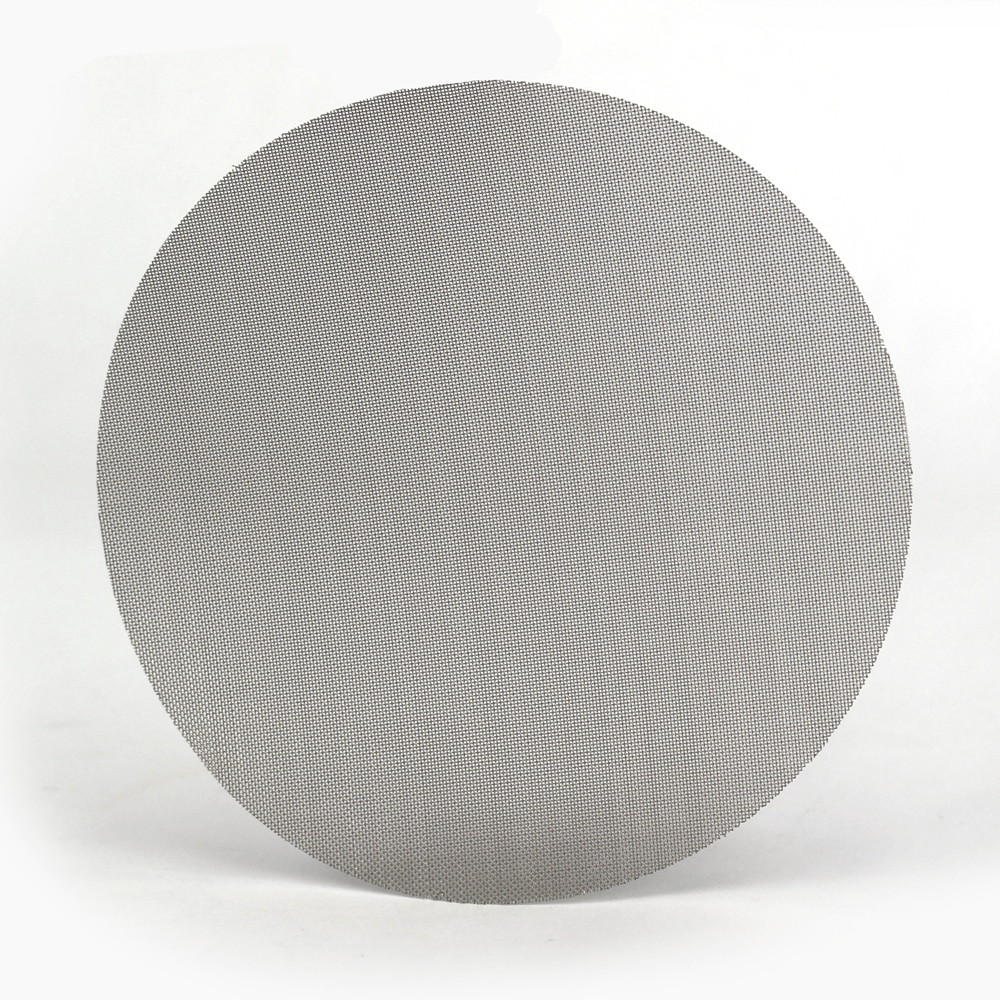

The Benefits of Extruder Screens

September 9, 2022

Whether you are producing plastic bottles, caps, or clothing, polymer material needs to be formed into a desired shape. The extrusion process is often used to produce these shapes.While there are many circumstances that can cause product failure, contaminants in plastic are the most common. Removing contaminants from the melt is the common focus manufacturers share in an effort to produce quality products.

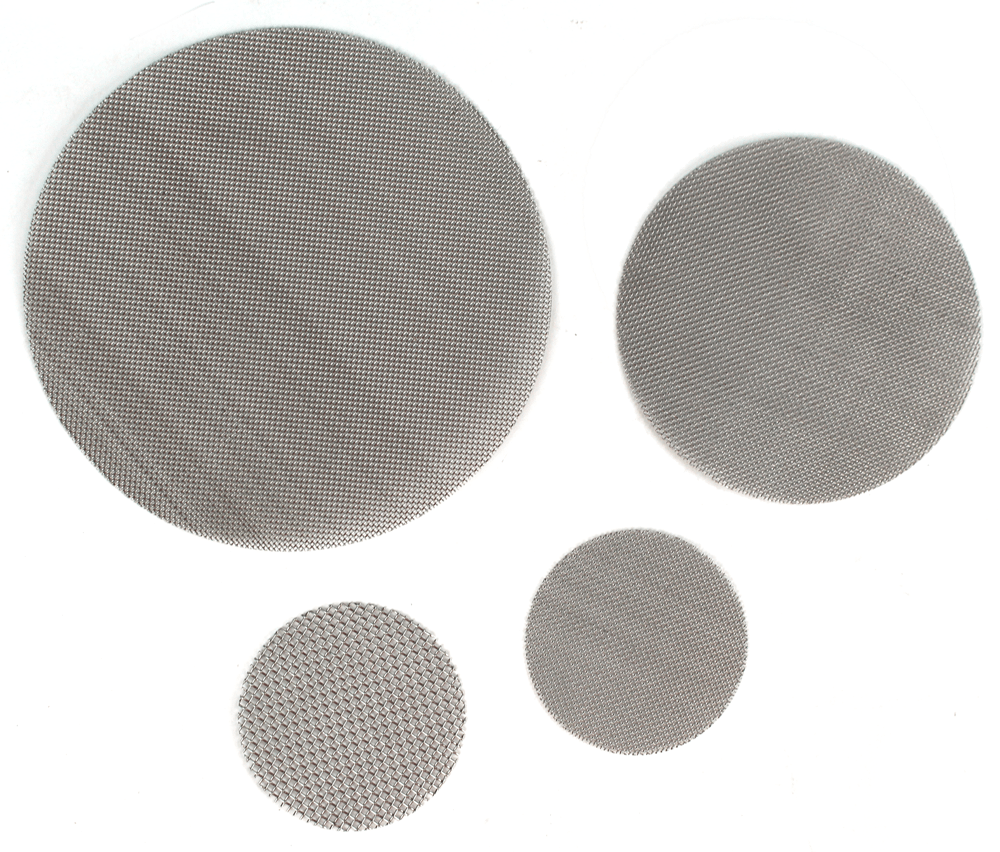

Extruder Screens, commonly known as screen packs, are woven wire filtration systems welded together and made into a variety of shapes and sizes specific to production needs. Melted material is pushed through this wire mesh screen to remove any contaminants. Depending on the level of decontamination and pressure requirements, different layer configurations and mesh opening sizes can be used.

No matter the shape or size, IMS has the extruder screens to fit your needs. Available in plain (carbon) steel and stainless steel, we also offer made-to-order extruder screen packs. For all your extrusion needs, trust the team who has been servicing Extruders for over 65 years.

-

Calculating Heat Load for a Circuit

August 24, 2022

Application Procedure

Use the following formula and method to calculate heat load for one cooling circuit. This will help determine suitability of the Smartflow Mold Temperature Regulator to your process.- Select material from the table at right and calculate BTU/hr using the formula below. Shot weight is the total drop

including cold runner (if any).

BTU/lb x Shot Weight (oz.) x 225 = BTU/hr

Cycle Time (sec) - Find BTU/hr along the X axis of the graph below. Locate the desired steel temperature along the Y axis of the graph. Find the spot where the X and Y values intersect.

- The graphed line nearest this intersection point represents the difference in temperature between the incoming water and the Mold Temperature Regulator set point (ΔT).

- The Smartflow Mold Temperature Regulator should work in your application if the sum of the incoming water temperature and the ΔT value is between 80° and 120°F.

Every mold is different! The effectiveness of the Mold Temperature Regulator relies on the ability of the resin shot to heat the mold, and the efficiency of the cooling lines inside the mold.

NOTE: These graphs and information are intended as a general guide for sizing and initial setup of the mold temperature regulator. Due to the different mold designs, results may vary from the graphs.

Typical Heat Values of Plasticized Resin*

Material BTU/lb

ABS …………………………………………………………… 81

Acrylic ………………………………………………….. 109

Nylon …………………………………………………….. 183

Polycarbonate ……………………………………. 112

Polyethylene – High Density ……… 276

Polyethylene – Low Density ……… 202

Polypropylene ………………………………….. 291

Polystyrene …………………………………………. 88

SAN ………………………………………………………… 88Example:

A molder is using nylon material in a four-cavity mold with a shot weight of .90 ounces (including the runner). The cycle time is 12.5 seconds with a mold steel temperature of 180°F. BTU/hr formula is as follows:

183 BTU/lb x .90 oz. x 225 = 2964.6 BTU/hr

12.5 secSee the One Water Circuit Graph below left for the differential temperature (ΔT) value. Add 70°F incoming water temp. to

the ΔT value (20°F). This is the beginning set point for the mold temperature regulator, and may be adjusted as needed.

Mold Temperature vs. Heat Input for 36-1/2” Water Circuit and

Five Different Values of ΔT

Mold Temperature vs. Heat Input for 21-1/2” Water Circuit and

Five Different Values of ΔTThese graphs were generated by simulated molds, with BTU input varied by electric heaters. The water line path through each mold was 7∕16″ dia.

- Select material from the table at right and calculate BTU/hr using the formula below. Shot weight is the total drop

-

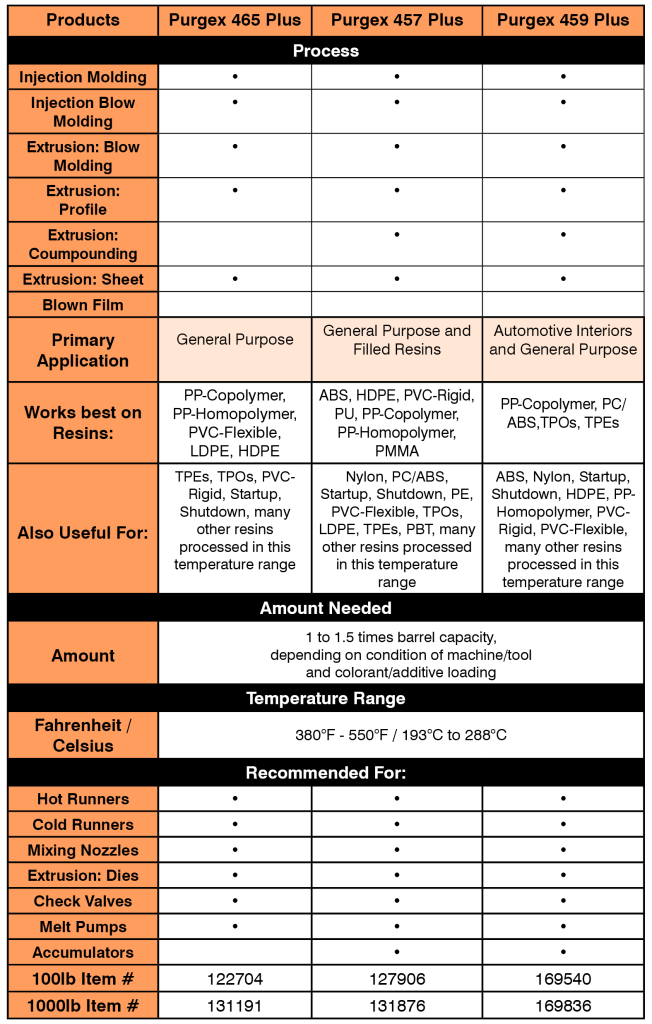

Purgex Purging Compounds

-

Air Wipe™

August 12, 2022

Provides a Uniform, 360° Stream of Air – Perfect for non-contact blow-off, cleaning, drying and cooling of extruded shapes, pipe, cable, hose etc.

- Performs better, runs quieter and is much more efficient than conventional air nozzles in such applications.

- Helps Reduce Production Costs

- 5 Year Warranty

Use To:

- Blow-off dust and dirt

- Remove excess coatings

- Dry after printing or plating

- Cool hot, extruded shapes

Can be supported by the compressed air supply pipe. Tapped holes (¼”-20) on the bottom of the body can also be used for mounting.

Variable Velocity

Thickness of Plastic Shim between cap and body (.002” standard) determines force and flow of air stream. Thicker and thinner Shims (sets available below) can be used to increase or decrease airflow.

A pressure regulator on the compressed air supply provides infinite control of flow, force and air consumption.

NOTE: Use of an Air Filter Separator is essential for proper operation.Circular Styling

Directs a consistent flow of air over the entire surface.Quiet

Meets or exceeds OSHA noise requirements.Split Design

Allows easy installation around the surface of the material moving through itLow Air Consumption

Helps reduce production costsAluminum Construction

(NOT recommended for use in corrosive environments)How Does it Work?

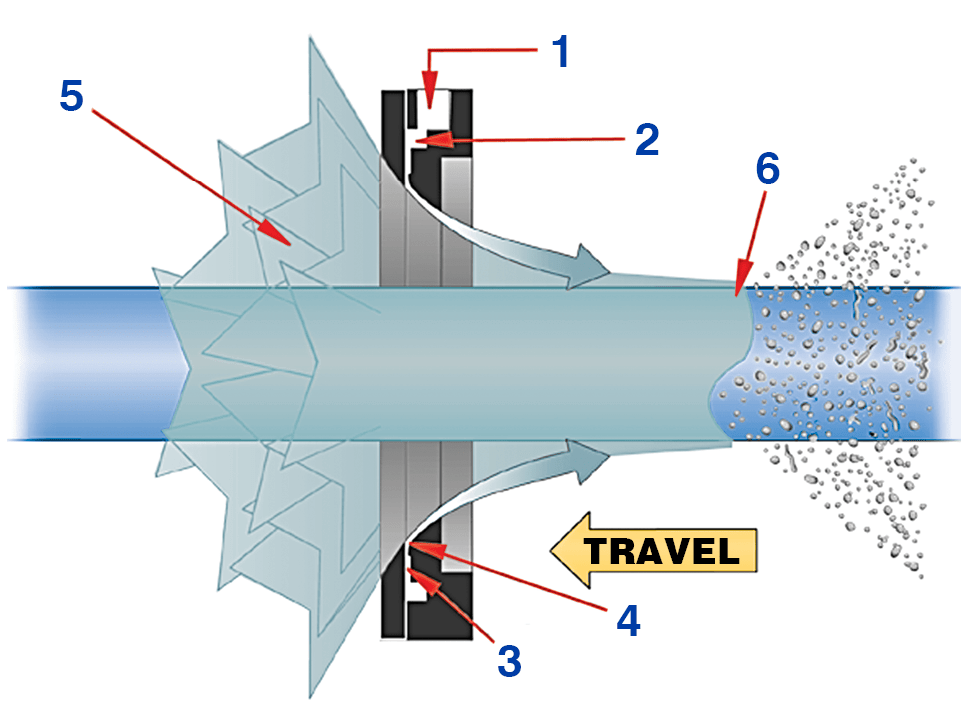

Compressed air flows through an inlet (1) of the Air Wipe into an annular chamber. (2) It is then throttled through a small ring nozzle (3) at high velocity. This primary airstream adheres to the coanda profile (4), which directs it down the angled surface of the Air Wipe. A low pressure area is created at the center (5) inducing a high volume flow of surrounding air into the primary airstream. As the airflow leaves the Air Wipe, it creates a conical 360° ring of air that attaches itself to the surface of the material running through it (6), uniformly wiping the entire surface with the high velocity airflow.

No Moving Parts — Nothing to Wear Out or Break!2 Styles to Match Any Application

Standard Air Wipe

- The best in non-corrosive environments

- Designed to work where temperatures do not exceed 150°F (66°C)

- Complete package including a general purpose PVC hose sized up to 4” (120mm)

Super Air Wipe

- Ideal choice for corrosive environments

- Choose from Aluminum models rated up to 400°F (204°C) or Stainless Steel models rated to 800°F (427°C) depending on your operating temperatures

- Constructed with high quality stainless steel screws, shims along with stainless steel wire braided coupling hose sizes up to 4” (120mm)

Perfect for Hundreds of Applications:

- Drying after paint, cleaning, plating or coating

- Cool hot extruded shapes

- Dry extruded profiles, rod & medical tubing

- Blow excess water off auto door gaskets

- Dry tube, hose, wire, & fiber optics

- Clean paint gun tips

- Clean strips or ribbons

- Blowoff of dust and contaminates

- Uniformly wipe surfaces

- Eliminate solution carryover – stop contamination

- Remove excess coatings, water and oil

- Minimize solution loss due to drag-out

- Dry screen printed or in jetted surfaces

-

IMS Custom Projects

August 11, 2022

IMS Company was founded on helping molders with their processing needs. From innovative new products (some brought to us by molders), to technical help with your equipment and processes, to products off the shelf – we have been there for our customers for 73 years.

Not every problem can be solved with a standard solution and not every product is available through a catalog or website. It is circumstances like these that led to the founding of IMS – someone needed a product to solve a problem, that was not in a catalog.

IMS has been involved in quite a few custom projects over these many years. These were projects that filled various needs as stated to us by our customers.

Some of those needs include:

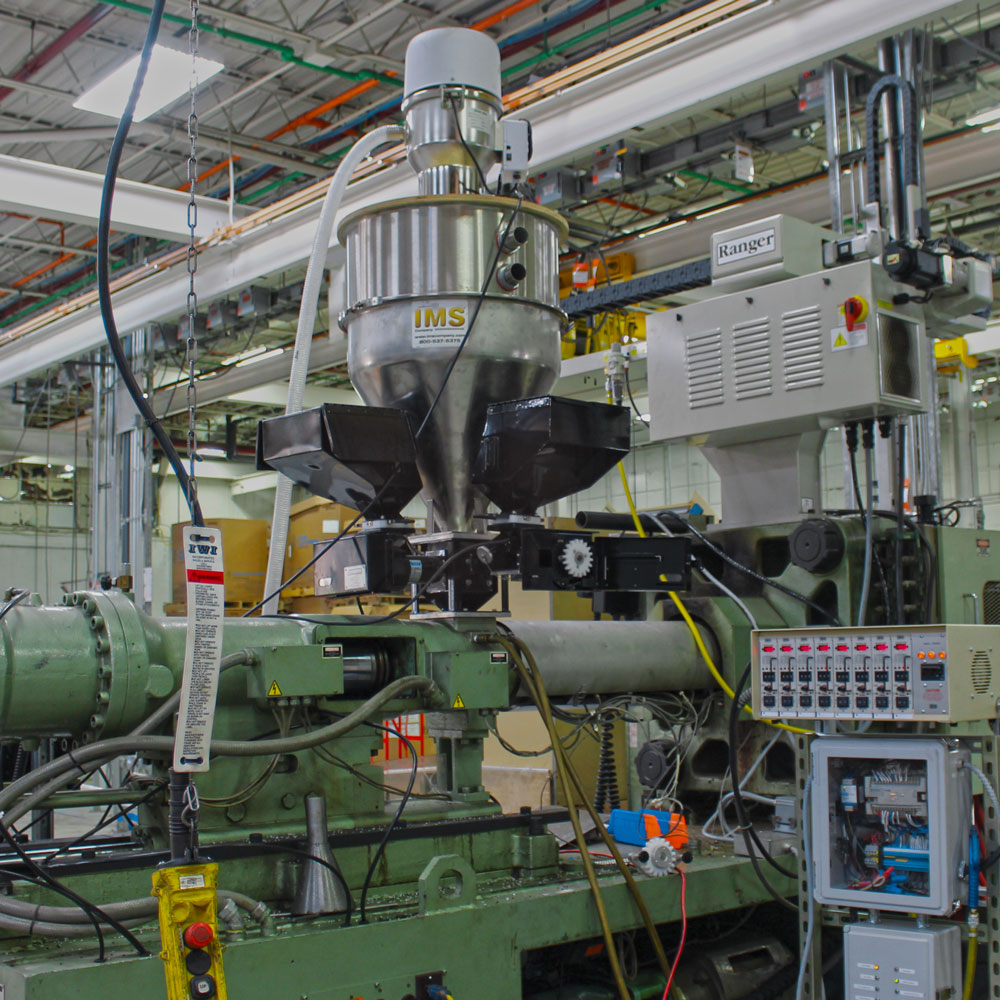

A customer expressed a concern about machine mounted dryers swaying with the motion of the machine. IMS built a mounting fixture where the dryers are mounted on a floor fixture, and the dried material is conveyed to the machine.

Another item we’ve built many times is a takeoff box for a surge bin. These were built in all shapes and sizes, with various sizes and numbers of ports. The photo to the right is an example for a customer that required 4 ports to feed more material to their machines.

A third example is a de-dusting station. A customer was molding clear parts and wanted to reuse the regrind. Unfortunately there was too much dust in the regrind and the customer needed a plan to remove it. This unit (pictured below) utilizes a customized frame, an standard vacuum loader, and a portable cyclone de-dusting machine.

These are three more examples of IMS is helping customers with the issues they are having.

From large scale cylindrical parts to the smallest complex helixes, IMS has the full range of services to handle your project from initial product design to finished goods delivery.

Send your drawings, Set up a meeting, Invite us for a field visit. -

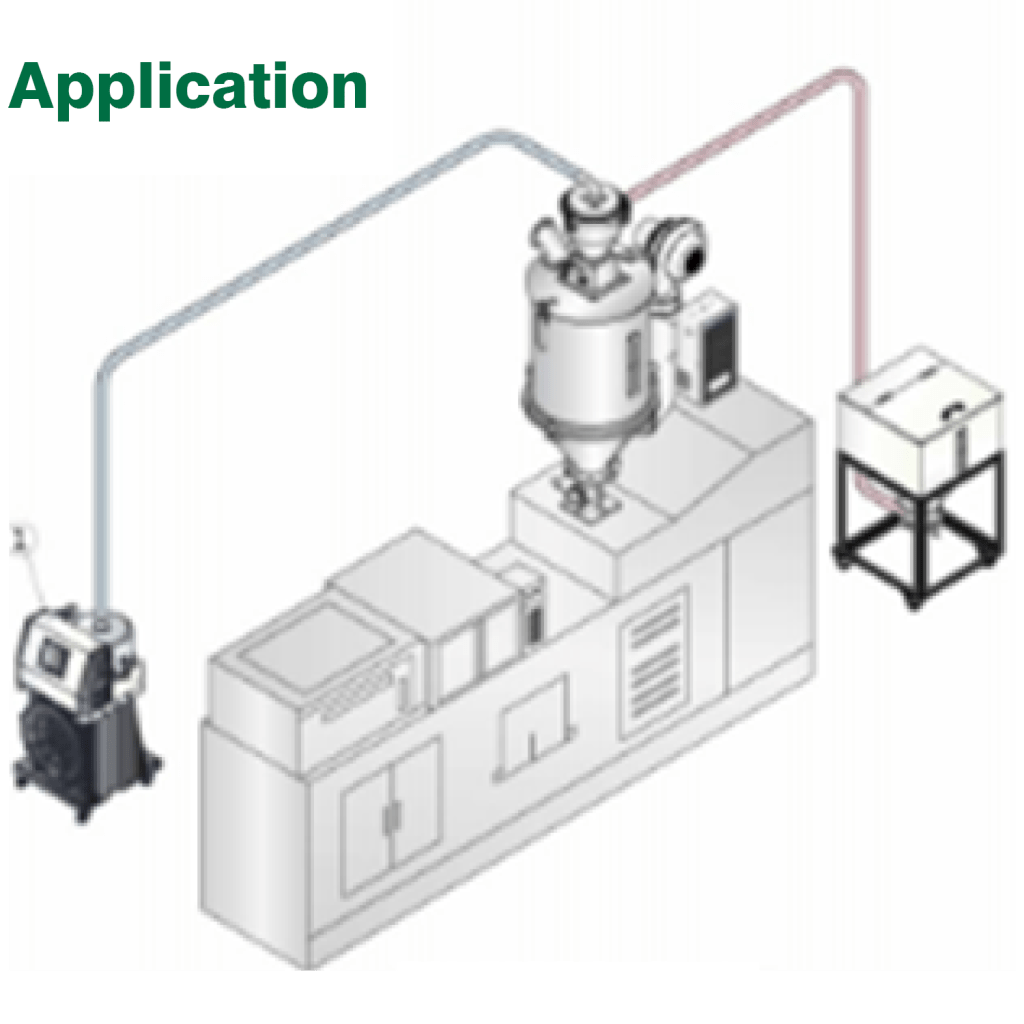

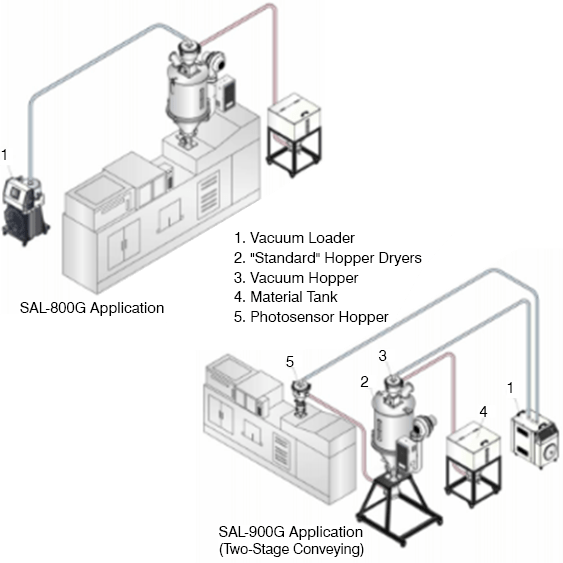

New Shini Hopper Loader Systems

Single Station Hopper Loader Systems

August 4, 2022

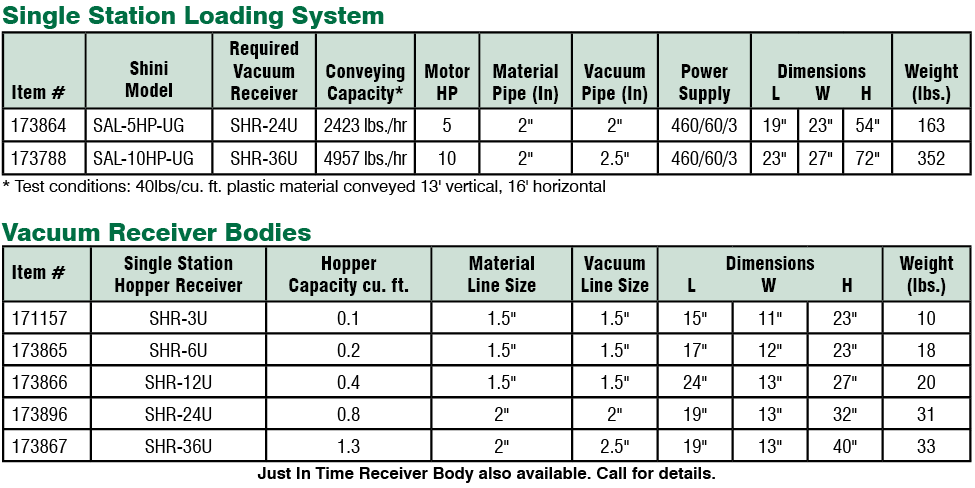

Heavy Duty Blowers with Separate Single Receiver Body

Features

• Floor Level Blower & Controller

• Separate Stainless Steel Receiver

• Microprocessor Controller

• Audible Material Shortage Alarm

• RS485 Communication Interface

• On board controller compatible with Shini SPV-U Proportional Valve (see page 657)

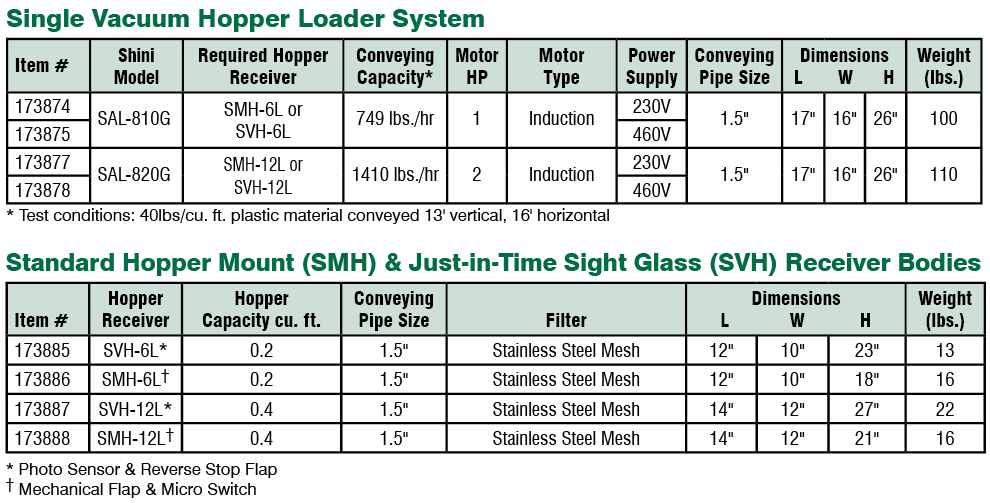

Single Vacuum Hopper Loader Systems

Floor Level Blowers with Separate Receiver Body

Shini USA SAL-G Single Vacuum Hopper Loader Systems are designed to convey material over long distances with a combination floor-level vacuum system & separate receiver body. The receiver body is mounted to the machine/hopper while the main unit’s vacuum motor and controls are located on the blower for easy control and maintenance. Each unit comes with microprocessor controls, digital display, air filter, and low material alarm.

Features

• Floor Level Blower & Controller

• Heavy Duty Casters

• Microprocessor Controller

• Audible Material Shortage Alarm

• RS485 Communication Interface

Multi Station Hopper Loader Systems

Heavy Duty Blowers and Multi-Station Receiver Bodies

Shini SAL-UG-122/124 Multi-Station Loader Systems are designed to convey material to two or four separate stations with a combination floor-level vacuum system & separate receiver bodies. The receiver bodies are mounted to multiple machines/hoppers while the main unit’s vacuum motor and controls are located on the blower for easy control and maintenance. Each unit comes with microprocessor controls, digital display, air filter, and low material alarm.

Features

• Floor Level Blower & Controller

• 2 or 4 Hopper Loading System

• Separate Stainless Steel Receiver

• Microprocessor Controller

• Audible Material Shortage Alarm

• RS485 Communication Interface

• 460 Volt/60/3 Phase

-

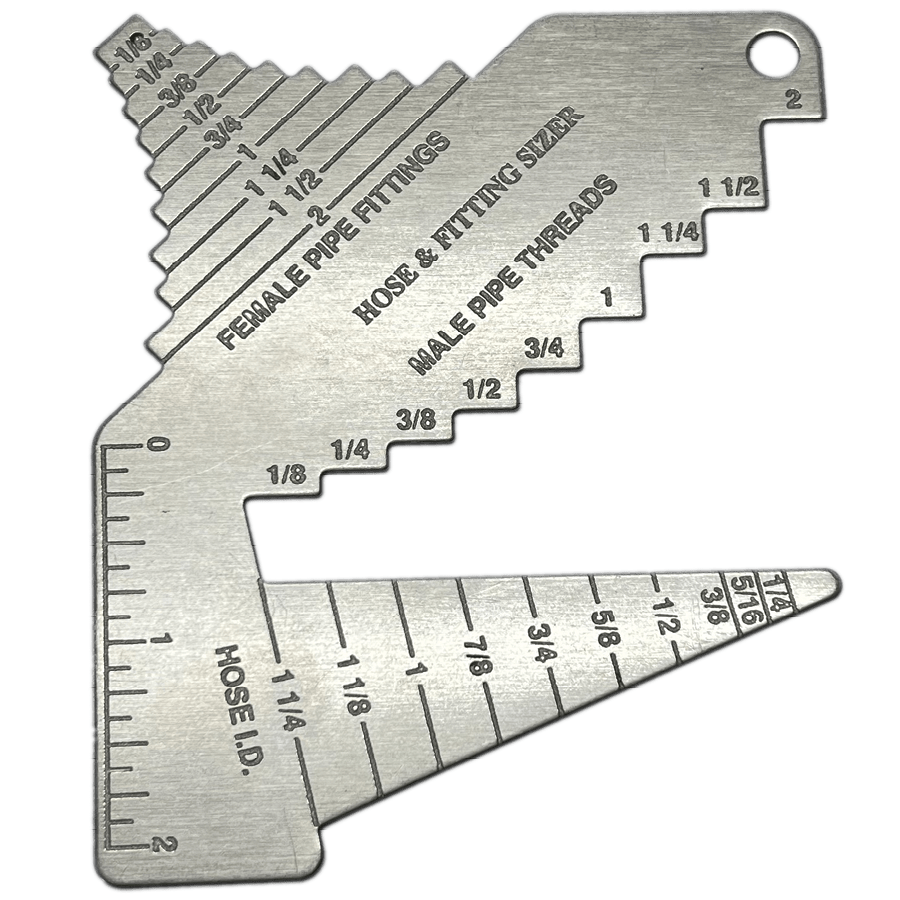

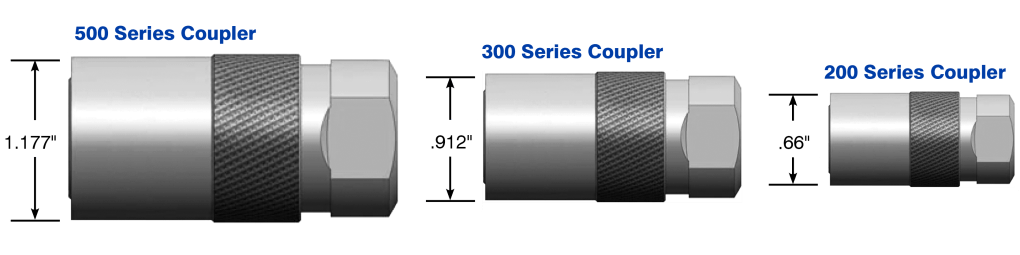

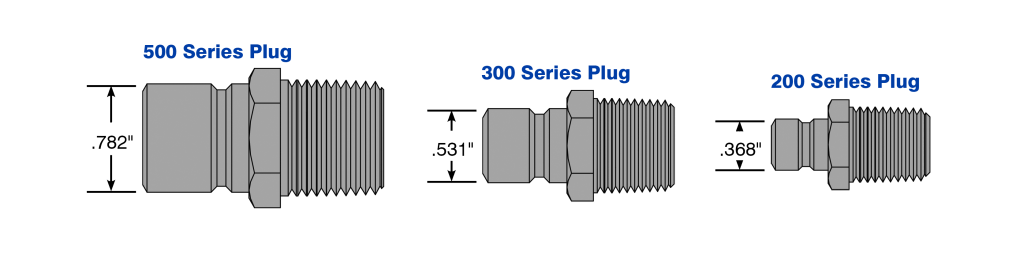

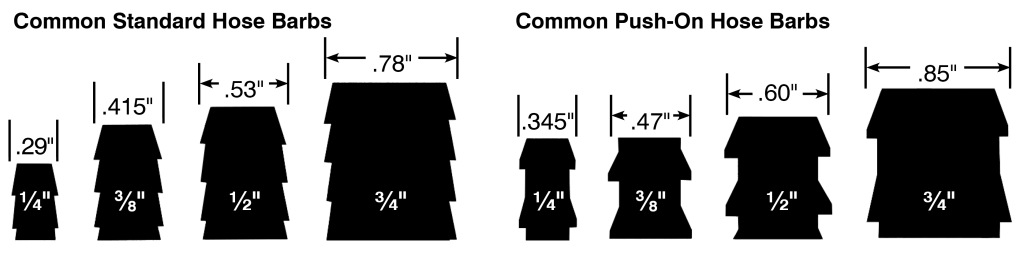

Quick Change Fittings & Thread Profile Sizing

July 21, 2022

IMS Hose and Fitting Sizer

Made Exclusively by IMS for Injection Molders

For fast, accurate hose I.D. and pipe thread identification- Easy to use, compact

- Decrease installation time

- Great for mold setup and maintenance

Durable 22 Gauge Stainless Steel

With etched numbers and letteringCoupler / Waterline / Thread

Quick Reference Charts

Pipe Thread Data

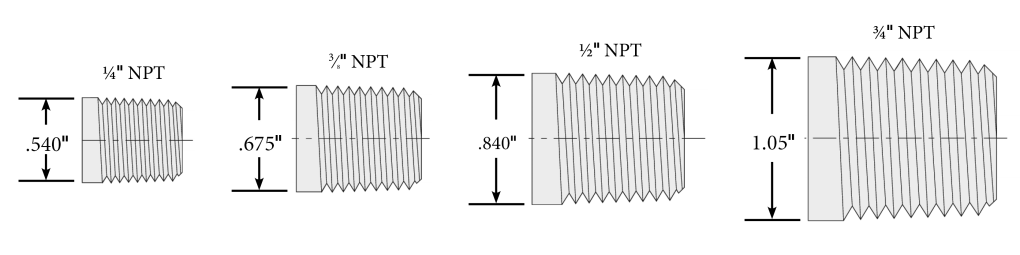

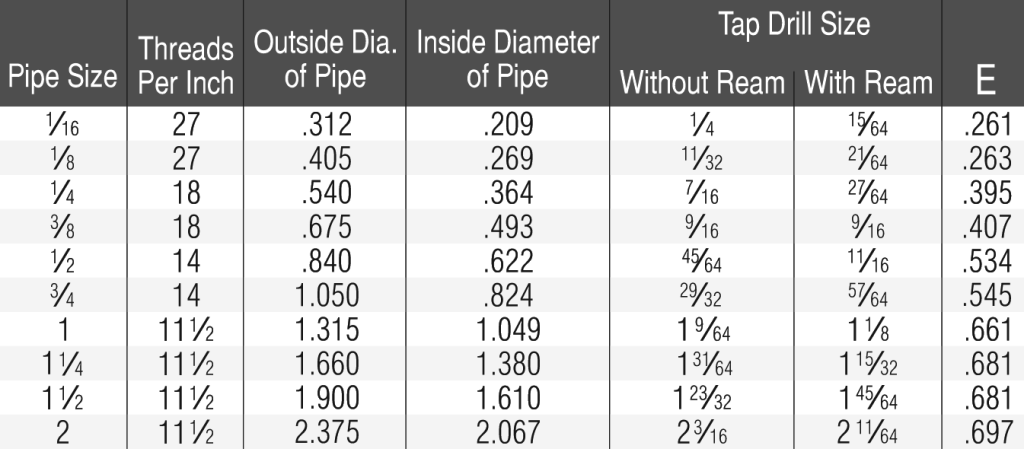

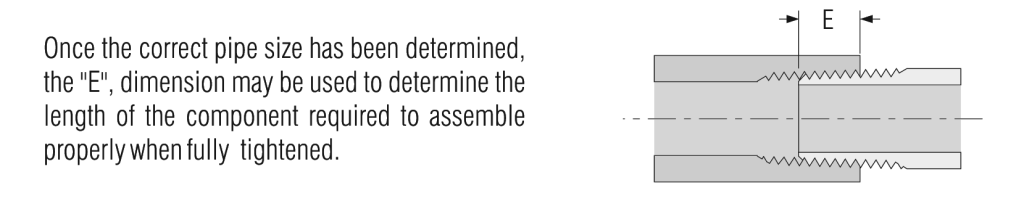

Most ordering mistakes are caused be measuring the pipe size of the fitting or component incorrectly. The normal size of any pipe does not in the fact refer to either the outside diameter (O.D.) or the inside diameter (I.D.) of the pipe. The table lists standard pipe sizes along with the actual O.D. and I.D. for each size. Keep in mind that manufactures may slightly modify these dimensions to strengthen or enhance the performance of a product.

-

Custom Project

Mobile Blending Station

July 19, 2022

IMS Company was founded on helping molders with their processing needs. From innovative new products (some brought to us by molders), to technical help with your equipment and processes, to products off the shelf – we have been there for our customers for 73 years.

Not every problem can be solved with a standard solution and not every product is available through a catalog or website. It is circumstances like these that led to the founding of IMS – someone needed a product to solve a problem, that was not in a catalog.

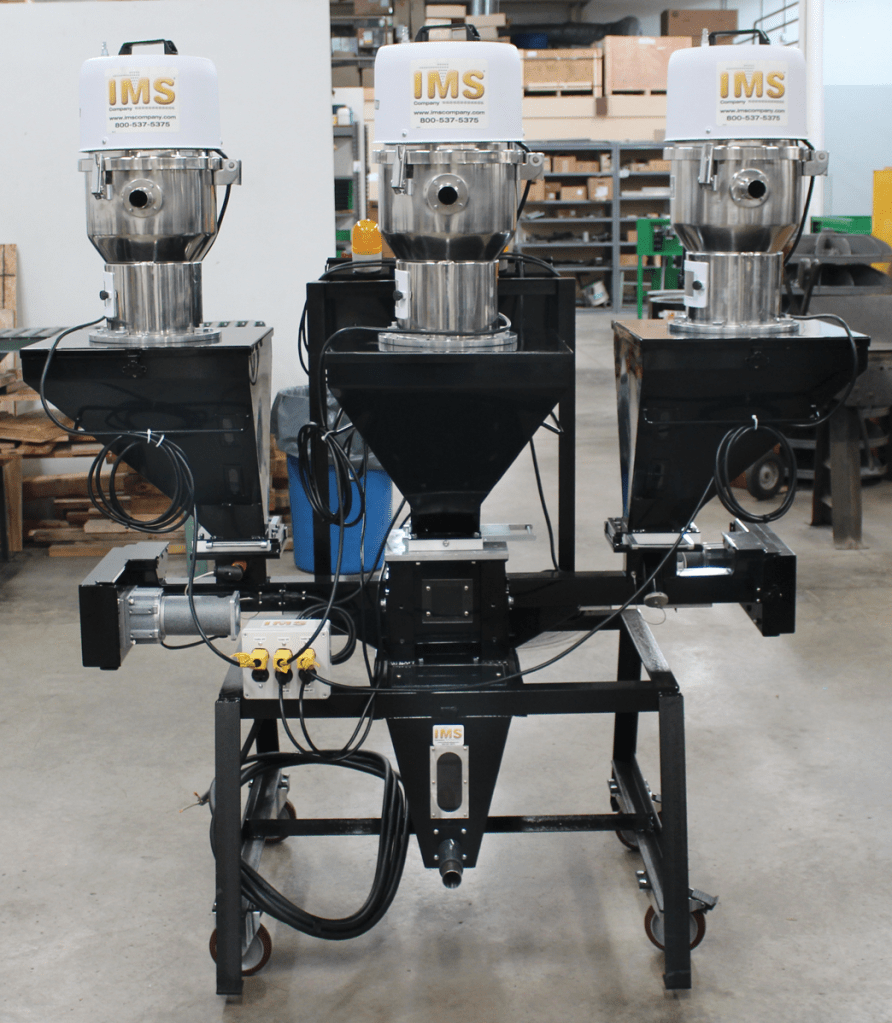

IMS has a extensive catalog of products and solutions, but as history has shown, sometimes a customized solution is in order.For example, the photo below is mobile blending station that was created based on a customer’s particular need. This customer needed a product to provide a more precise color blend as well as a unit that could move from machine to machine.

The end result (above) uses two volumetric feeders to provide separate additives, and a center hopper to accept the virgin material. All three hoppers are loaded with material, some using a vacuum loader. The additives, and the virgin material are dumped into a takeoff box, where the mix is pulled to the machine. The system is tied to the controls of the molding machine to cycle and create each batch.

My point here is the IMS Advantage – IMS can take a problem or need as defined by a molder, and develop a solution to help solve the issue, and help with productivity.

This all started when I visited a customer’s molding shop, observed their process and heard details of what they needed. The blending station is one of many ideas I’ve seen or been involved with in my forty years with IMS. This is what we do best.

We can help you. We want to help you. Why not let us?

Pat Fox

Acting General Manager

IMS Company