IMS Company

A trusted partner for the plastics processing industry, offering a wide range of high-quality, process improving products at competitive prices. We are a diversified distributor specializing in supplies, components, auxiliary machinery, and equipment. With 75 years of industry experience, our stocked warehouse ensures fast, reliable delivery, helping you maintain peak production efficiency. Whether you need innovative products, expert support, or tailored solutions, IMS Company has the expertise and resources to keep your operations running smoothly. Visit us at imscompany.com for more!

For 75 years, one thing has never changed at IMS — our single-minded focus on providing products and services designed to help your shop increase efficiency and ramp up productivity.

Check out IMS on YouTube!

Blogs

July 28, 2025 – Why Keiba Gate Cutters Excel in Precision Cutting

June 3, 2025 – Sizing a Desiccant Dryer for Plastic Injection Molding

May 7, 2025 – Mold Cleaners

January 7, 2025 – Time to Purge

November 4, 2024 – Plant Shutdown

October 22, 2024 – Prepare Your Shop for Winter

September 11, 2024 – New Injection Press Setup

August 26, 2024 – D-limonene

August 14, 2024 – Mold Rust Prevention

July 9, 2024 – Mold Cleaner vs. Mold Release

March 25, 2024 – Part Diverting Systems

March 13, 2024 – Chill Out

February 22, 2024 – Why is Moisture a Problem

February 19, 2024 – What is a Vacuum Loader

February 5, 2024 – Injection Molding Nozzle Tips

January 29, 2024 – Metal Separation

May 30, 2023 – Benefits of Insulation

April 22, 2023 – Sustainability

March 20, 2023 – Dew Point Meter/Monitor

March 2, 2023 – IMS Lime Buster

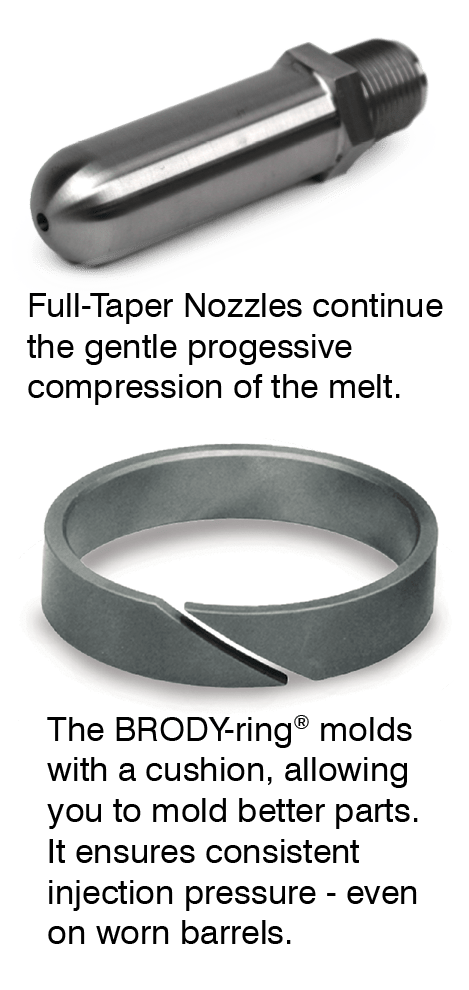

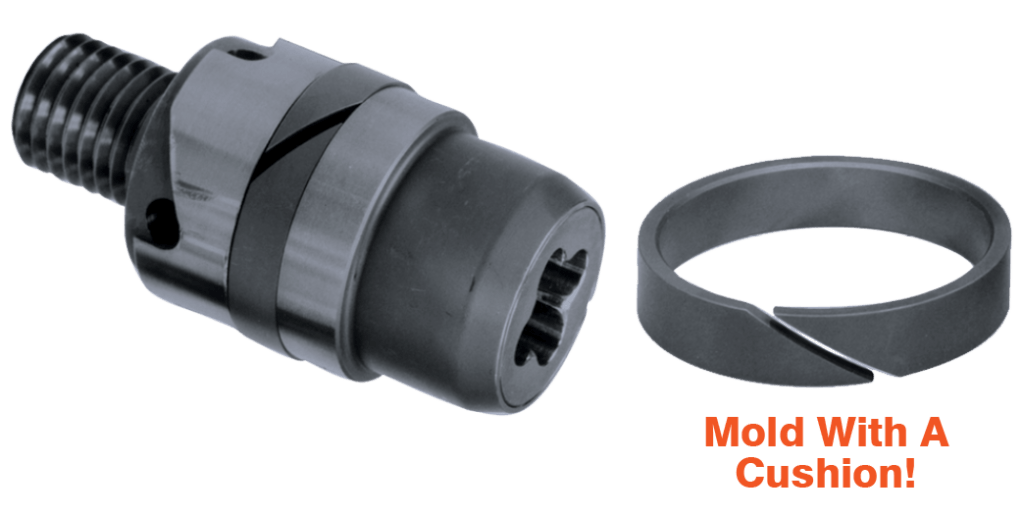

March 1, 2023 – IMS Brody Ring

January 30, 2023 – Clean Room Manufacturing

January 1, 2023 – Heater Band Wiring

December 21, 2022 – IMS Select Drum Tumbler

December 8, 2022 – Plastic Granulators

December 6, 2022 – Mold Setup Cart

November 28, 2022 – Eliminate Static and Dust

November 18, 2022 – Extending the Life of Your Heater Band

November 2, 2022 – How to Set Barrel Zone Temps

September 9, 2022 – The Benefits of Extruder Screens

August 24, 2022 – Calculating Heat Load for a Circuit

August 17, 2022 – Purgex Purging Compounds

August 12, 2022 – Air Wipe

August 11, 2022 – IMS Custom Projects

August 4, 2022 – New Shini Hopper Loader Systems

July 21, 2022 – Quick Change Fittings – Thread Profile Sizing

July 19, 2022 – IMS Custom Project

June 20, 2022 – Safety First

June 15, 2022 – IMS Screw Tip Brody Ring

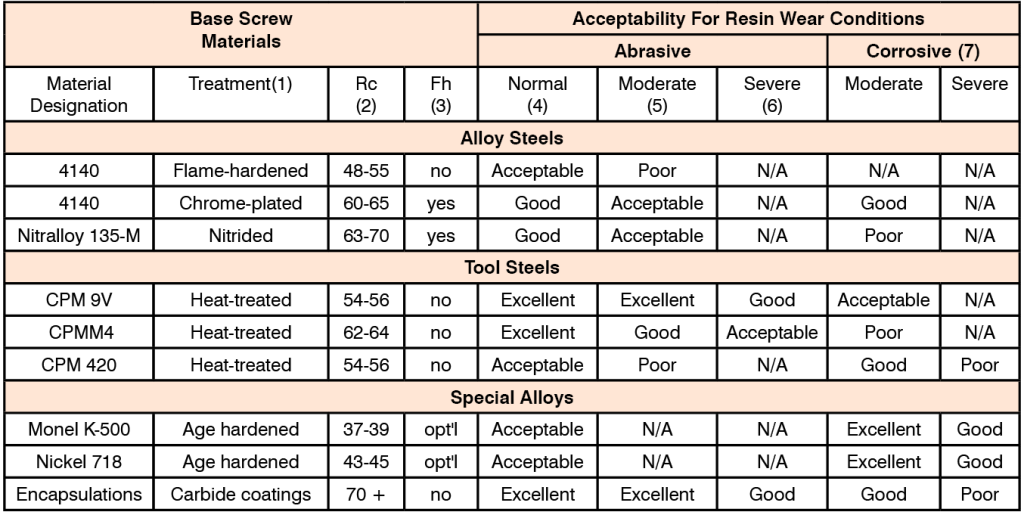

June 15, 2022 – Screw Material Guidelines

June 15, 2022 – Screw Tip Wear Issues

June 15, 2022 – Essential Barrel Information

June 9, 2022 – Mold Safety Checklist

June 2, 2022 – Why Choose High Quality Desiccant?

May 26, 2022 – Circulators 101

May 19, 2022 – Sizing a Chiller

April 25, 2022 – Mold Temperature Control Product Selection

April 19, 2022 – Selecting the Right Gate Cutter For Your Job

April 12, 2022 – Barrel Insulation Blankets

April 4, 2022 – Quick Mold Change

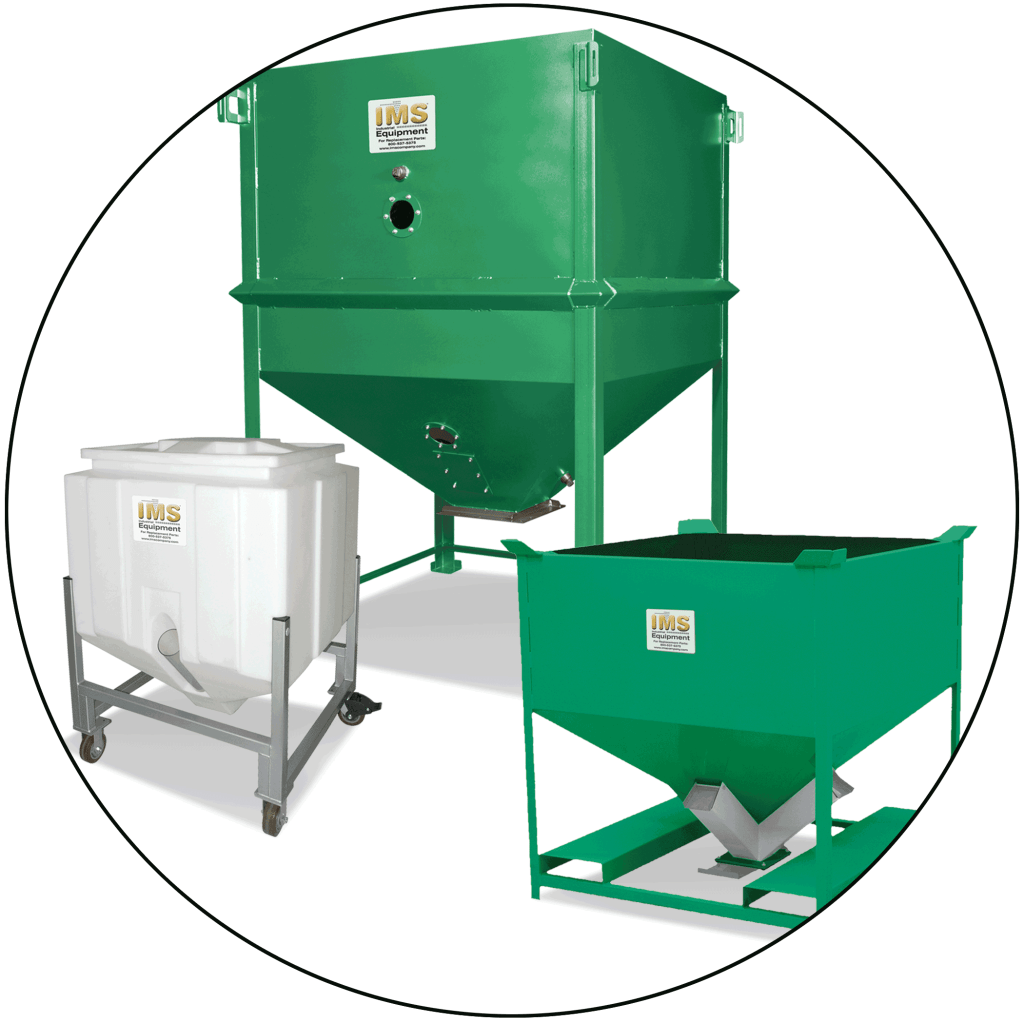

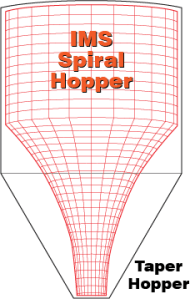

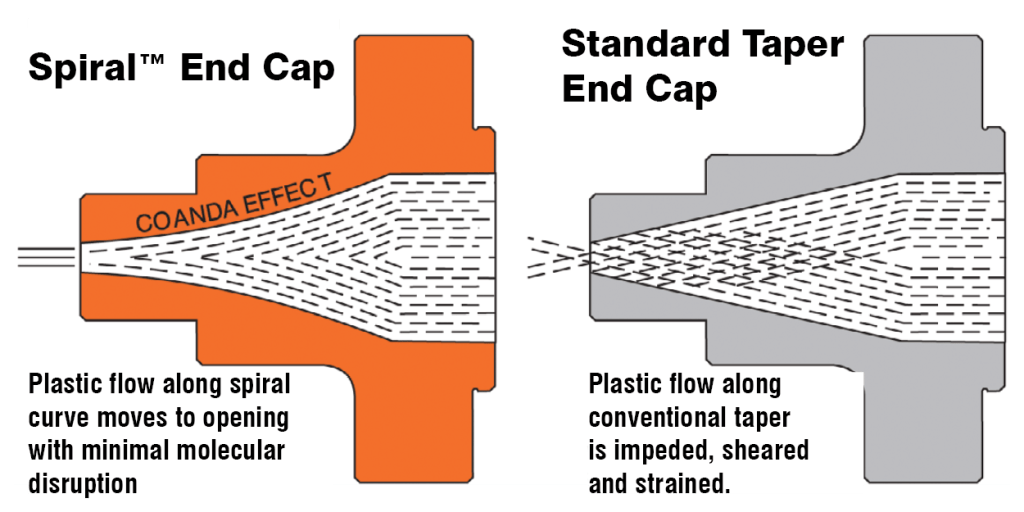

March 14, 2022 – Spiral Technology

February 17, 2022 – Screw Tips

-

Circulators 101

March 6, 2024

Circulators (Thermolators, Temperature Controllers) are essential components in injection molding processes, primarily utilized for controlling the temperature of molds so that as the part cools after injection, it maintains dimension, shape and structure – ensuring consistent quality and efficiency. Controlling the mold temperature is critical to good parts. You can get good melt flow, and the cavity can fill quickly and fully, but if the part is not cooled properly then a good melt flow means nothing.

Circulators need to be compatible with the injection molding machinery and seamlessly integrated into the overall manufacturing setup for efficient operation. Regular maintenance and monitoring of circulators are essential to ensure they continue to function optimally, thereby avoiding downtime and production delays. In advanced setups, circulators may be integrated into the overall automation system of the injection molding process, allowing for real-time monitoring and control of temperature parameters.

Here’s how circulators are typically used in injection molding:

- Cooling: Cools the molds after each cycle. Rapid cooling is essential for improving cycle times and overall productivity.

- Heating: In some cases, circulators may also be used for heating the molds to specific temperatures.

- Thermal Stability: Ensure thermal stability throughout the injection molding process, which is crucial for preventing defects and maintaining part quality.

- Energy Efficiency: Modern circulators often come with energy-saving features to optimize energy consumption during the temperature control process, contributing to cost-effectiveness and sustainability.

- Process Optimization: By precisely controlling the temperature of molds, circulators play a vital role in optimizing the process for different materials and product specifications.

Overall, circulators play a critical role in maintaining temperature control and ensuring the quality, efficiency, and reliability of injection molding operations. Their proper selection, installation, and maintenance are essential considerations for any injection molding facility.

IMS offers several options for temperature control needs: Circulators, Mold Temperature Controllers

You May Also Need:

Heat Transfer Fluids

A Quick Comparison Of Heat Transfer Mediums

• Water — Limited use range: 32° to 212°F. Encourages corrosion.

• Uninhibited Glycols — Allow temperatures to 250°F, but 2½ times more corrosive than water, if not neutralized.

• Automotive antifreeze — Contains corrosion inhibitors, but can foul heat transfer surfaces in less turbulent systems.

• UG-10 Ethylene Glycol — Low silicate formula provides good corrosion protection at a relatively low price.

• EG-17 Ethylene Glycol — Industrial inhibitors coat surfaces and impact pH for maximum corrosion protection.

• Pro-17 Inhibited Propylene Glycol — Non-Toxic Heat Transfer Fluid With Maximum Protection Against Acidity and Corrosion.

• PG-1 Hi-Heat Transfer Fluid — The Ultimate, Non-Toxic Fluid For Non-Pressurized Heating To 600°F.

• FF-1 Oil System Flushing Fluid — Improves heat transfer for faster cycles.

• PSC Plus Oil System Cleaner — Maximizes heat transfer for more parts and increased quality.In addition, how efficiently any of the above units work is directly tied to how clean your mold passages are. Any buildup of scale can affect the transfer of heat. The passages need to be checked and maintained regularly. To help with that, IMS offers the Limebuster which helps remove the scale buildup in mold passages. Just 1/64″ of scale can reduce the heat transfer rate up to 40%. Using an acid/water mixture, the fluid is circulated by a low pressure pump. The fluid helps dissolve the scale slowly so good heat transfer can return. This type of unit also is used to clean heat exchangers.

While the above is basic in its presentation, the message is clear; IMS understands and can help. IMS has the expertise and the equipment to help maintain and even improve your process. Good parts and reduced scrap means you make money.

That is what we are here to help with. Call IMS Today for all your Injection Molding needs.

-

Safety First!

June 20, 2022

On November 3, 2021 the Bureau of Labor Statistics reported private industry employers documented 2.7 million nonfatal workplace injuries and illnesses in 2020, down from 2.8 million in 2019, a decrease of 5.7 percent.

Keep your people safe and your business running smoothly.

While it may lack the bells and whistles, Workplace Health and Safety is a topic of high importance in industrial professions. In order to properly implement safety precautions and foster a culture that results in lasting sustainable protocol that prioritizes safety, productivity, quality, and efficiency, you’ll need to train all employees on best safety practices and regularly conduct workplace safety training. With such a large topic, it can be overwhelming to find the tools to fit your workplace needs. In this blog, we will examine tips, tricks, and resources on how to effectively implement workplace safety.

Resource: OSHA Online Training

OSHA opened for business in April 1971 and covered 56 million workers at 3.5 million workplaces. Today, 105 million private-sector workers and employers at 6.9 million sites look to OSHA for guidance on workplace safety and health issues.

As reported by the U.S. Department of Labor, rates of accidents and health problems in the workplace went from 10.9 cases per 100 workers in 1972, to 2.8 cases in 2018.

A great resource for all employees – workers, supervisors, and managers – is the OSHA Authorized Outreach Training online courses. There you will find a wide range of courses for various industries.

Communication

Communicate safety hazards with your peers and managers. Ensure all employees understand WHAT the safety procedures are and WHY they are in place. Host regular safety training to build and maintain emergency response skills so employees can quickly respond when incidents happen and keep operations running smoothly. Have signage to alert employees to possible hazards. Encourage workers to ask questions and speak to their supervisor if they need more help.

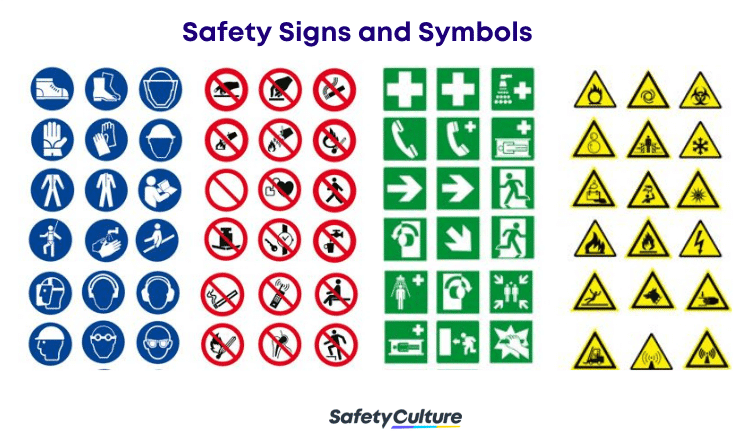

Safety Signs

Safety signs and symbols are easily recognizable graphic labels that represent general protocol and safety instructions in workplaces, establishments, or public spaces. The appearance of safety signs and symbols can sometimes vary depending on the country or region, but their general goal is to communicate safety information that transcends language barriers and can be interpreted globally.

Safety signs and symbols inform individuals of the presence of hazards, dangers, or risks associated with certain items or places. Free Download: the Required Components of OSHA Safety Signs Guide.

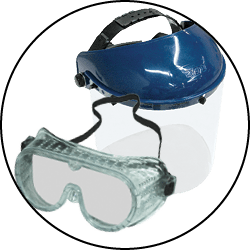

Personal Protective Equipment (PPE)

Always provide all employees with Personal Protective Equipment to minimize the risk of injury. This can include gloves, helmets, eye and hearing protection, face masks, harnesses, and more. Check often that PPE is in good working order and fits properly.

Clean Up

Keep equipment and floors clean and free of debris. This helps you prevent slips and falls on wet or dirty floors and avoid accidents on poorly maintained tools and machines.

Take A Break

Give your employees a chance to rest, recharge, and focus. Tired employees are a liability in the workshop as they can potentially harm themselves or others.

According to the National Safety Council, 75% of injury and illnesses leading to days away from work are over exertion and bodily reaction, as well as slips, trips, and falls.

Slow Down

Encourage your team to prioritize safety over speed. Put procedures and workflows in place to intended to avoid risk and make sure all employees follow them.

Keep Records

Maintain a record of all training sessions, and attendance for those sessions so you know who’s been trained on what. Keep records of all safety incidents and accidents. Use these records to for training purposes to identify what caused the issue, how it can be prevented or handled in the future.

Finally, Stay Up to Date!

Even with extensive workshop experience, workshop safety is a skill that should be refreshed regularly. Procedures, protocols, or even equipment can change frequently in the workplace, so ensure workers are always aware and up to date with these changes.

-

Mold Clamps, Bolts & Washers

Molding Safety Checklist

June 9, 2022

Inspection

Inspect the press and surrounding areas including all auxiliary equipment for the following:

- Is the area clean and free of all potential hazards?

- Is other electrical equipment that could be hazardous during the operation locked out?

- Are the correct mold straps used to strap the mold together?

- Did you perform the daily inspection on the hoist/crane?

Holes in Platens

Mold Clamps

- Are the clamps the correct size for the mold?

- Are the clamps cracked or bent?

- How many clamps are needed to hold the mold?

- Are the clamps spaced evenly? It is essential that the clamps are placed properly.

Clamp Installation

- Make sure the bolts for the clamps are the correct size and grade.

- Make sure you are using the proper grade of bolts.

- Are the bolts in good condition?

- Check the manufacturer’s torque information to see how much torque needs to be placed on the bolts.

- Don’t rely on air pressure to torque bolts properly!

Don’t re-use bolts from a previous application Closed-Toe Mold Clamps

For basic applications use mold clamps that have a slot to accept the bolt. They never fall off the bolt.

Open-Toe Mold Clamps

Take great care when handling open-ended clamps. They may slip and fall to the floor or down the chute when the tech is trying to bolt it in.

-

Molecular Sieve Desiccant

June 2, 2022

Why Buy High-Quality Desiccant?

Desiccants can get contaminated or ruined by off-gases of certain resins. A general rule is to change the desiccant every 18 months.

- Good drying depends on good airflow. Better desiccant provides better airflow by creating less dust to clog your filters. Clean desiccant also helps prevent material contamination.

- The desiccant you buy today is going to dry tons of your material for tens of thousands of cycles. The per-part cost of high quality desiccant is almost too small to compute. The quality and productivity advantage is too great to ignore.

Regeneration Temperature: between 375°F and 600°F Molding problems, particularly in humid months, often trace back to poor drying caused by stale desiccant. The fact is this: desiccant goes bad. Desiccant captures moisture in its pores, which become blocked with contamination over time. And only fresh desiccant gives your dryers a chance to thoroughly dry your material in hot, humid weather.

Type 4A has smaller pores. It is less subject to contamination but adsorbs slightly less moisture.Type 13X has larger pores. It adsorbs more moisture but is more subject to contamination. Most dryer manufacturers recommend Type 13X for most applications.

1∕8″ Beads (4 x 8) allow better airflow, but adsorb less moisture.

1∕16″ Beads (8 x 12) adsorb more moisture, but allow less airflow. - Good drying depends on good airflow. Better desiccant provides better airflow by creating less dust to clog your filters. Clean desiccant also helps prevent material contamination.

-

Sizing a Chiller

for Injection Molding

May 19, 2022

The Right Type

Most refrigeration is designed for static loads, like in a meat cooler.

In plastics processing, heat is added to and removed from the mold

during every cycle. Select a chiller designed for active heat loads.The Right Size

Although an undersized chiller will cost less to buy, the chiller will be running at full capacity, resulting in higher operating costs. And even

then, you may have trouble consistently keeping the mold cold. Chillers are rated in tons; one ton equals the ability to transfer 12,000 BTUs/hr. The tonnage rating should be stated at a specific “leaving water temperature and at a specific ambient temperature”.

Choose a chiller that can achieve the anticipated water temperature that your process will need and the rate of BTU’s required. Producing colder water than necessary will cost in two ways; initially

for the equipment and continually to operate it. IMS Chillers are Rated based on actual testing. Avoid arbitrary Tonnage claims and select the chiller producing enough BTU’s and

a temperature required for your process.Water Flow through the Mold

At a flow of 10 gpm, chilled water must rise 12°F through the mold to

remove 1,000 BTU/minute. At a flow of 3 gpm, the temperature must

rise 40°F to remove 1,000 BTU.

If low flow is due to the mold’s design, the only solution is having

the mold reworked. But if normally occurring water deposits are

clogging the lines, water line cleaner, IMS Lime Buster III, can greatly

boost mold flow and increase heat transfer.Computing Size for IMS Chillers (2 Methods)

Method 1 (Based on coolant temperature and flow rate)

To determine chiller tonnage required, you must calculate the

delta T between the inlet and outlet water temperatures and the

rate of flow in gallons per minute. Measuring the delta T requires a

thermocouple or thermometer. To perform a load test: 1.) Strap a

thermocouple to the inlet water line of the processing equipment and

wrap it with tape to hold it in place. 2.) Strap a thermocouple on the

outlet water line of the processing equipment to record the amount of

heat the water is picking up in your equipment.

To measure flow rate of the water place a flow meter on the outlet

water line of your equipment. If a flow meter is not available, simply

disconnect the outlet line and let the water pour into a five gallon

bucket while you time it with a watch. This provides you with the

“GPM” (gallons per minute) rate of discharge.

Now you have the necessary information to size a unit properly. Use

the following formula to calculate your equipment’s BTU’s of required

cooling.BTU = Constant (weight of water) x GPM x Temperature Differential

Multiply the fluid flow (GPM) by 500. Multiply the result by the

temperature differential or rise (return water temperature minus the

input or supply water temperature). Divide the result by 12,000 and

you now have your required rating.Example: 500 Constant (weight of water)

x 10 GPM (gallons per minute)

5000

x 12° Temperature Differential (or rise)

60,000 Required BTU’s per hour

12,000 EACH 12,000 BTU’s requires 1 Ton of Cooling

= 5 Ton (This equipment would require a 5 Tons capacity)Method 2 (Based on material use and melt temperature)

You can also calculate the proper tonnage using the following formula:

Tonnage = A × (B – C)

Removal Capacity

where: A = Material use in lbs./hr.

Use actual lbs./hr., not machine’s capacity rating

B = Temperature of melt

C = Temperature of part when it comes out of moldRemoval = 12,000 BTU/hr./ton removal capacity of chiller system set

Capacity at 50°F, which includes estimated radiation losses, etc.

At 40°F, use 8,000. At 30°F, use 6,100. At 20°F, use 5,800.Example: 100 lbs./hr.

450° F melt temperature

150° F part temperature when mold opensTonnage = 100 x (450 – 150)

12,000= 100 x 300

12,00030,000

12,000

= 2.5

Use the next size up, in this case a three ton chiller, to avoid problems

caused by using an undersized chiller.Blow Molding

40#/Hr HDPE = 1 Ton 45#/Hr LDPE = 1 Ton

40#/Hr PET = 1 Ton 45#/Hr PP = 1 Ton

Minimum process flow = 4.8 GPM/ton @ 65 PSIExtrusion

Coating

40#/Hr LDPE = 1 Ton

Process flow required = 12 GPM/ton for direct roll coolingPipe & Profile

80 #/Hr ABS = 1 ton 90#/Hr PVC = 1 TonSheet

40#/Hr UHMWPE = 1 Ton 55#/Hr PP = 1 Ton

80#/Hr PVC = 1 Ton

50#/Hr HDPE = 1 Ton 75#/Hr PS = 1 Ton

55#/Hr LDPE = 1 Ton 75#/Hr ABS = 1 Ton

Process flow = 8 GPM/ton for direct roll coolingEquipment Cooling

Gearbox cooling = 0.5 Ton/Inch of extruder barrel

Screw cooling = 0.5 Ton/Inch of extruder barrel

Feed throat cooling = 0.33 Ton/ Inch of extruder barrel

Barrel cooling = 1 Ton/Inch of extruder barrel

Eddy current clutch (light load) = 0.2 Ton/HP

Eddy current clutch (normal operation) = 0.05 Ton/HPInjection Molding

Mold Cooling

30#/Hr HDPE = 1 Ton 40#/Hr Nylon = 1 Ton

65#/Hr PVC = 1 Ton

35#/Hr LDPE = 1 Ton 50#/Hr PS = 1 Ton

40#/Hr PET = 1 Ton

35#/Hr PP = 1 Ton 50#/Hr ABS = 1 ton

Hot runner molds = 1 Ton/10.5 KW hot runnerMachine Cooling

10 HP Hydraulic Motor HP = 1 Ton

Feed throat cooling = 1 Ton (machines under 400 ton use 1/2 ton)Thermoforming

180#/Hr PE = 1 Ton 250#/Hr HIPS = 1 Ton

240#/Hr PVC = 1 Ton Rail Cooling = 3 Tons

Minimum process flow of 4.8 GPM/TonOther

Mold room heating = 25 BTU/FT2 Vacuum pump = 0.1 Ton/HP

Non-mold room heating = 50 BTU/FT2 Water pump = 0.2 Ton/HP

Mold room cooling = 80 BTU/FT2

Air compressor without after cooler = 0.15 Ton/HP

Air compressor with after cooler = 0.20 Ton/HPCommon Conversion Factors

To Convert From To Multiply By

Boiler HP Btu/Hour 33445.7

Cubic Centimeters Gallons (US) 0.00026

Cubic Feet Gallons (US) 7.48052

Cubic Inches Gallons (US) 0.00433

Cubic Meters Gallons (US) 264.172

Feet Meters 0.3048

Gallons (US) Cubic Meters 0.003785

Gallons (US) Liters 3.7854

Gallons(US)/Minute Liters/Second 0.06309

Inches Millimeters 25.4

Kilowatts Btu/Hour 3414.4

Motor HP Btu/Hour 2547.16

Motor HP KW 0.746

Ounces Grams 28.3495

Pounds Kilograms 0.4536

Pounds/Sq Inch Bar 0.06895

Pounds/Sq Inch Kilograms/Sq Cm 0.07031

Pounds/Sq Inch Kilopascals 6.89476

Pounds/Sq Inch Feet of Water 2.3067

Square Feet Square Meters 0.0929

Square Inch Square Centimeter 6.4516

(°F-32) x 5/9=°C

(°C x 9/5) +32=°FWeighted Water Tests

GPM x ΔT = Chill Ton

24#/Min x ΔT = Chill Ton

200GPM x ΔT = Twr Ton

30#/Min x ΔT = Twr Ton

250% Ethylene Glycol vs Freeze

by Volume Protection10% 25°F

20% 15°F

30% 0°F

40% -15°F

50% -40°F

Flow Rates vs Temp Difference Per Ton

1.2 GPM = 20°F ΔT 4.8 GPM = 5°F ΔT

2.4 GPM = 10°F ΔT 9.6 GPM = 2.5°F ΔTPipe Sizing Guide for Schedule 40 Steel Pipe

(10’HD/100’ Run,10’/Sec Velocity Max)

½” = 3 GPM 1¼” = 25 GPM 2½” = 120 GPM 6″ = 900 GPM

¾” = 6 GPM 1½” = 40 GPM 3″ = 200 GPM 8″ = 1500 GPM

1″ = 12 GPM 2″ = 75 GPM 4″ = 400 GPM 10″ = 2400 GPMCommonly Used Equivalents & Formulae

1 HP = 2547.16 Btu/Hr 1 Cu Ft = 7.48 gallons (water)

1 Gallon = 8.33 lbs (water) 1 KW = 3414.4 Btu/Hr

1 KW = 1.341 HP Q = 4.5xCFMxDH = Btu (air cooling)PSI = ft of head

2.31

Pump HP = GPM x P(feet of head)

3960x(0.65 to 0.75) (Pump Eff)KW = Amps x Volts x 0.85 x 1.73

1,000Tower water make-up requirements: untreated 2% of flow rate, treated

1.5% of flow rate.Water cooled requires 3 GPM/Min/Ton

Lose 1.5% capacity per degree lower than rating

For assistance with sizing, contact the IMS Equipment Team at

sales@imscompany.com -

Mold Temperature Control

Product Selection Guide

April 25, 2022

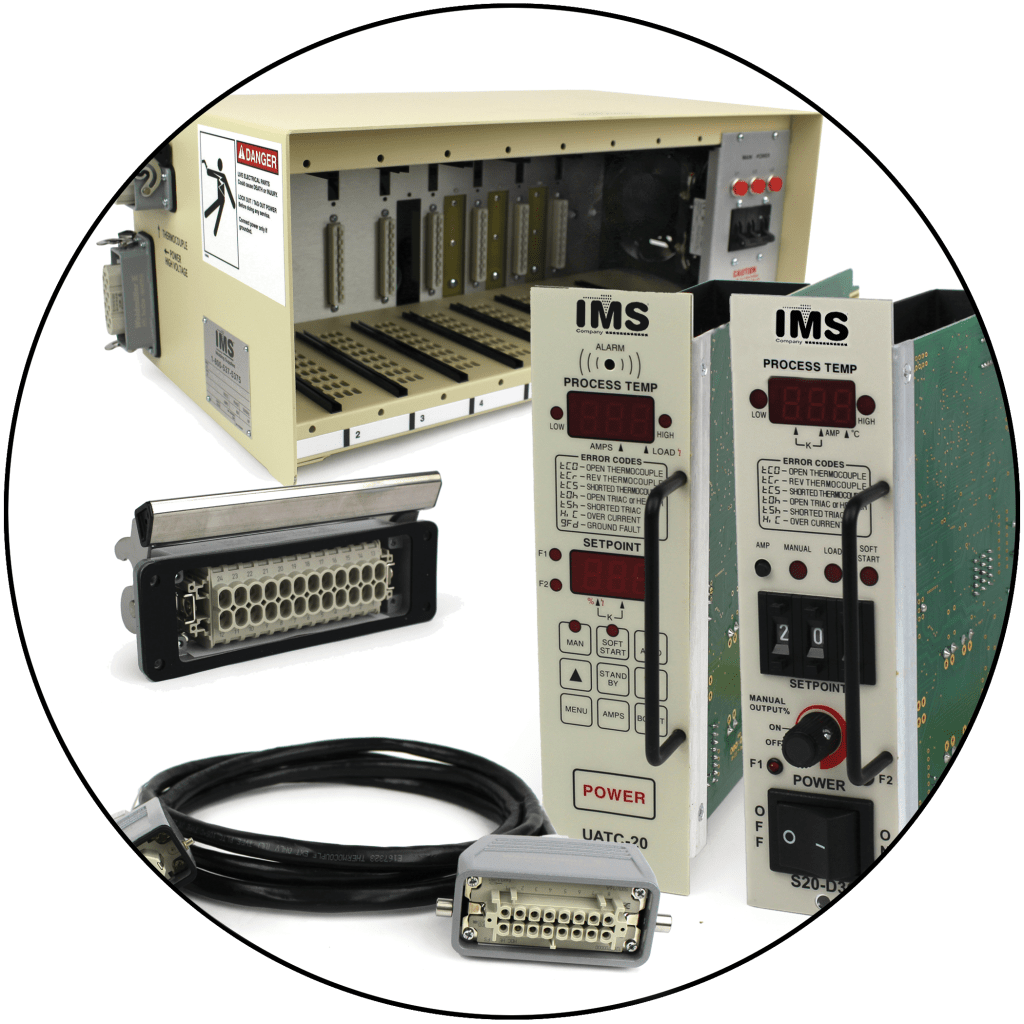

(All Images Clickable)

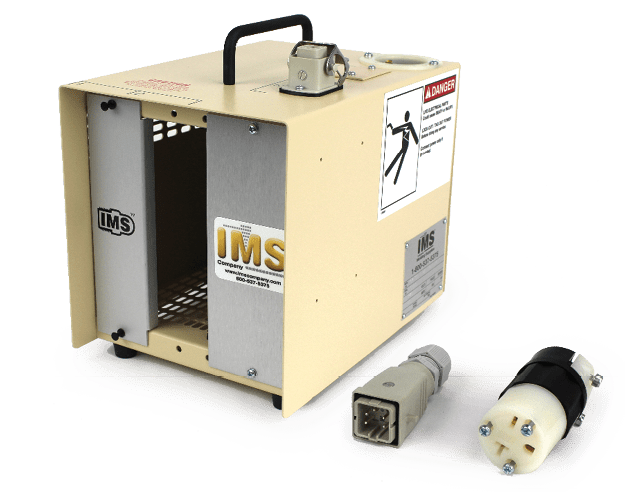

1. How Many Zones?

Side-Mounted Ventilation Fan and Phase Indicator Lights Standard

24 & 36 Zone Housing Assemblies Available – Inquire 1.800.537.53752. Specify AMPs Required Per Zone

15 AMPs proceed to #3

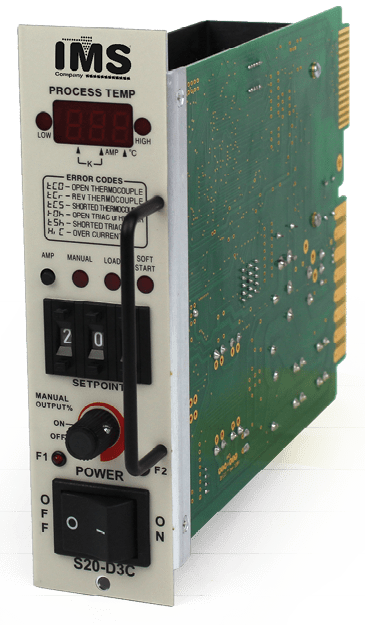

30 AMPs – Call product specialist at 1-800-537-53753. Control Module Preference

120V or 240V(Most Popular) Pgs. 244-245 IMS Catalog (46th)

Most Popular!

S20-D3C

Part #’s: 137679 (120V)

133753 (240V)

Rock-Solid Performance – Delivers Simple Operation and Reliability

• Manual buttons for fast and easy setpoint selection

50 / 60hzIMS Exclusive

UATC-20

Part #’s: 134360 (120V)

133752 (240V)

Intelligent design and advanced

Perfectly matched control for Hot Runners

• Advanced membrane keypad for multiple functions and displays

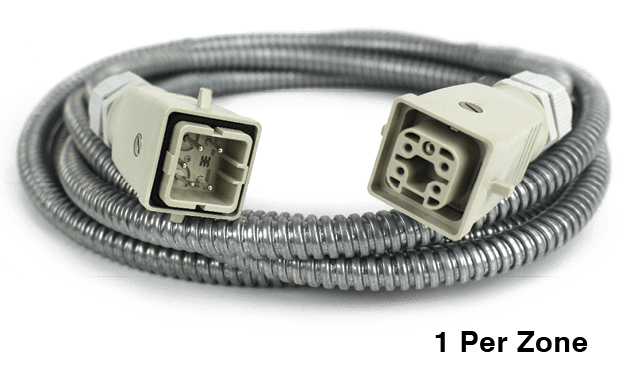

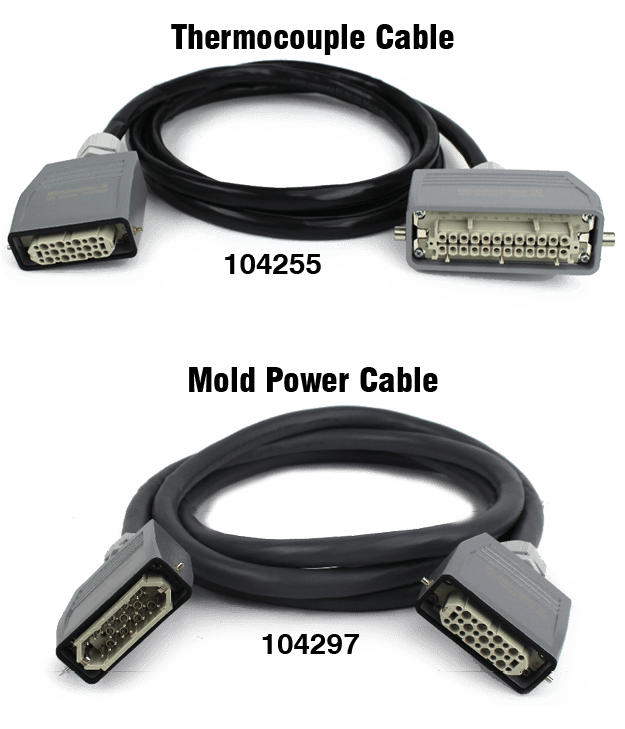

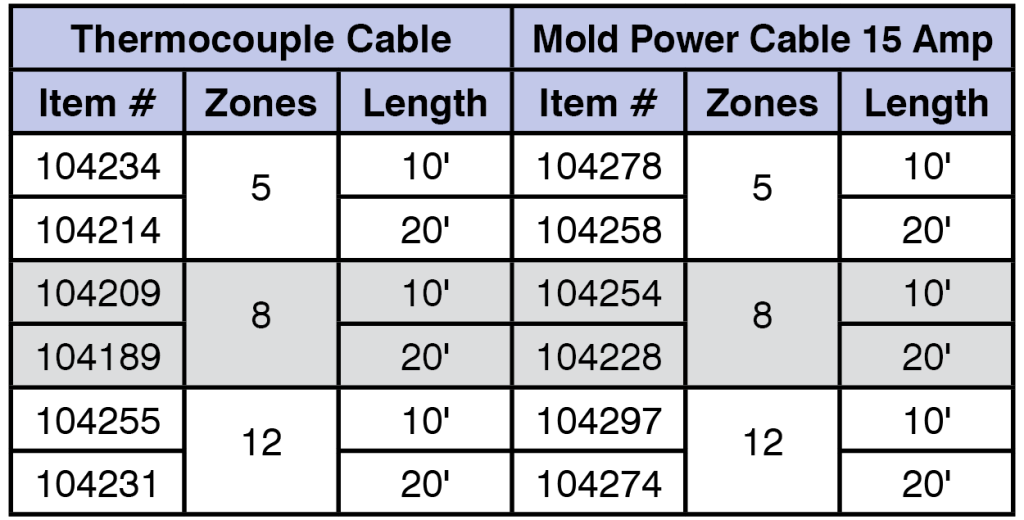

50 / 60hz4. Cables, Connectors &

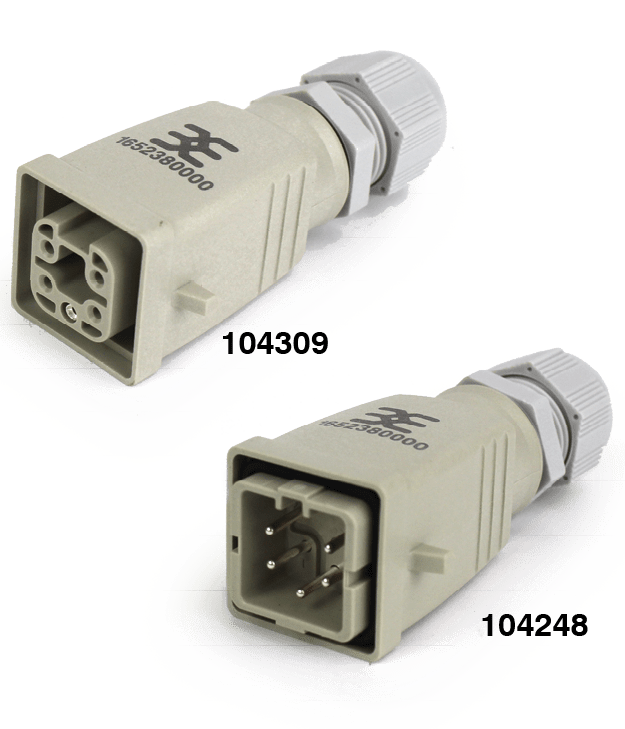

Terminal Boxes1 & 2 Zone Connectors

5, 8 or 12 Zone Cables – IMS Catalog Pg. 250 IMS Catalog (46th)

See Page 251 of the IMS Catalog (46th Edition) for

Mold End Connectors & Controller End Connectors5. Optional Accessories:

Floor Stands & Transformer Kits – pg. 253 (Transformers optional – include Floor Stands)

- Most customers ask about Transformers on

5, 8 & 12 Zone Systems - Customer chooses Transformer power capacity

- Blank Module Panels

- Most customers ask about Transformers on