IMS Company

A trusted partner for the plastics processing industry, offering a wide range of high-quality, process improving products at competitive prices. We are a diversified distributor specializing in supplies, components, auxiliary machinery, and equipment. With 75 years of industry experience, our stocked warehouse ensures fast, reliable delivery, helping you maintain peak production efficiency. Whether you need innovative products, expert support, or tailored solutions, IMS Company has the expertise and resources to keep your operations running smoothly. Visit us at imscompany.com for more!

For 75 years, one thing has never changed at IMS — our single-minded focus on providing products and services designed to help your shop increase efficiency and ramp up productivity.

Check out IMS on YouTube!

Blogs

July 28, 2025 – Why Keiba Gate Cutters Excel in Precision Cutting

June 3, 2025 – Sizing a Desiccant Dryer for Plastic Injection Molding

May 7, 2025 – Mold Cleaners

January 7, 2025 – Time to Purge

November 4, 2024 – Plant Shutdown

October 22, 2024 – Prepare Your Shop for Winter

September 11, 2024 – New Injection Press Setup

August 26, 2024 – D-limonene

August 14, 2024 – Mold Rust Prevention

July 9, 2024 – Mold Cleaner vs. Mold Release

March 25, 2024 – Part Diverting Systems

March 13, 2024 – Chill Out

February 22, 2024 – Why is Moisture a Problem

February 19, 2024 – What is a Vacuum Loader

February 5, 2024 – Injection Molding Nozzle Tips

January 29, 2024 – Metal Separation

May 30, 2023 – Benefits of Insulation

April 22, 2023 – Sustainability

March 20, 2023 – Dew Point Meter/Monitor

March 2, 2023 – IMS Lime Buster

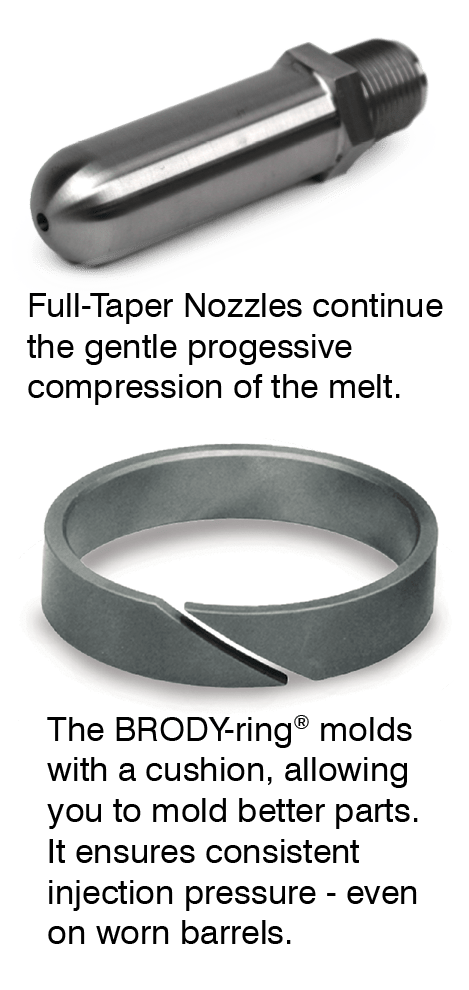

March 1, 2023 – IMS Brody Ring

January 30, 2023 – Clean Room Manufacturing

January 1, 2023 – Heater Band Wiring

December 21, 2022 – IMS Select Drum Tumbler

December 8, 2022 – Plastic Granulators

December 6, 2022 – Mold Setup Cart

November 28, 2022 – Eliminate Static and Dust

November 18, 2022 – Extending the Life of Your Heater Band

November 2, 2022 – How to Set Barrel Zone Temps

September 9, 2022 – The Benefits of Extruder Screens

August 24, 2022 – Calculating Heat Load for a Circuit

August 17, 2022 – Purgex Purging Compounds

August 12, 2022 – Air Wipe

August 11, 2022 – IMS Custom Projects

August 4, 2022 – New Shini Hopper Loader Systems

July 21, 2022 – Quick Change Fittings – Thread Profile Sizing

July 19, 2022 – IMS Custom Project

June 20, 2022 – Safety First

June 15, 2022 – IMS Screw Tip Brody Ring

June 15, 2022 – Screw Material Guidelines

June 15, 2022 – Screw Tip Wear Issues

June 15, 2022 – Essential Barrel Information

June 9, 2022 – Mold Safety Checklist

June 2, 2022 – Why Choose High Quality Desiccant?

May 26, 2022 – Circulators 101

May 19, 2022 – Sizing a Chiller

April 25, 2022 – Mold Temperature Control Product Selection

April 19, 2022 – Selecting the Right Gate Cutter For Your Job

April 12, 2022 – Barrel Insulation Blankets

April 4, 2022 – Quick Mold Change

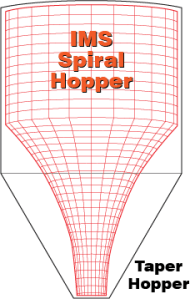

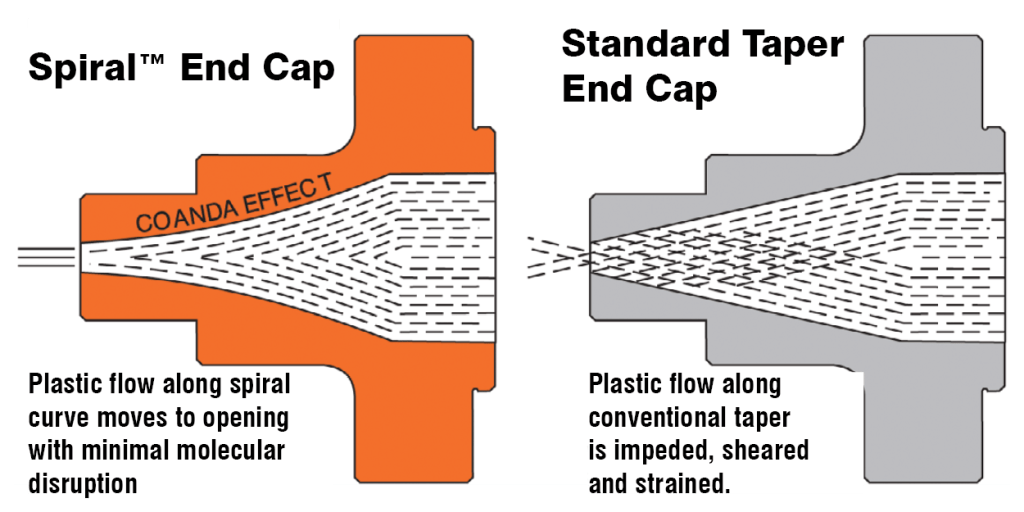

March 14, 2022 – Spiral Technology

February 17, 2022 – Screw Tips

-

Circulators 101

March 6, 2024

Circulators (Thermolators, Temperature Controllers) are essential components in injection molding processes, primarily utilized for controlling the temperature of molds so that as the part cools after injection, it maintains dimension, shape and structure – ensuring consistent quality and efficiency. Controlling the mold temperature is critical to good parts. You can get good melt flow, and the cavity can fill quickly and fully, but if the part is not cooled properly then a good melt flow means nothing.

Circulators need to be compatible with the injection molding machinery and seamlessly integrated into the overall manufacturing setup for efficient operation. Regular maintenance and monitoring of circulators are essential to ensure they continue to function optimally, thereby avoiding downtime and production delays. In advanced setups, circulators may be integrated into the overall automation system of the injection molding process, allowing for real-time monitoring and control of temperature parameters.

Here’s how circulators are typically used in injection molding:

- Cooling: Cools the molds after each cycle. Rapid cooling is essential for improving cycle times and overall productivity.

- Heating: In some cases, circulators may also be used for heating the molds to specific temperatures.

- Thermal Stability: Ensure thermal stability throughout the injection molding process, which is crucial for preventing defects and maintaining part quality.

- Energy Efficiency: Modern circulators often come with energy-saving features to optimize energy consumption during the temperature control process, contributing to cost-effectiveness and sustainability.

- Process Optimization: By precisely controlling the temperature of molds, circulators play a vital role in optimizing the process for different materials and product specifications.

Overall, circulators play a critical role in maintaining temperature control and ensuring the quality, efficiency, and reliability of injection molding operations. Their proper selection, installation, and maintenance are essential considerations for any injection molding facility.

IMS offers several options for temperature control needs: Circulators, Mold Temperature Controllers

You May Also Need:

Heat Transfer Fluids

A Quick Comparison Of Heat Transfer Mediums

• Water — Limited use range: 32° to 212°F. Encourages corrosion.

• Uninhibited Glycols — Allow temperatures to 250°F, but 2½ times more corrosive than water, if not neutralized.

• Automotive antifreeze — Contains corrosion inhibitors, but can foul heat transfer surfaces in less turbulent systems.

• UG-10 Ethylene Glycol — Low silicate formula provides good corrosion protection at a relatively low price.

• EG-17 Ethylene Glycol — Industrial inhibitors coat surfaces and impact pH for maximum corrosion protection.

• Pro-17 Inhibited Propylene Glycol — Non-Toxic Heat Transfer Fluid With Maximum Protection Against Acidity and Corrosion.

• PG-1 Hi-Heat Transfer Fluid — The Ultimate, Non-Toxic Fluid For Non-Pressurized Heating To 600°F.

• FF-1 Oil System Flushing Fluid — Improves heat transfer for faster cycles.

• PSC Plus Oil System Cleaner — Maximizes heat transfer for more parts and increased quality.In addition, how efficiently any of the above units work is directly tied to how clean your mold passages are. Any buildup of scale can affect the transfer of heat. The passages need to be checked and maintained regularly. To help with that, IMS offers the Limebuster which helps remove the scale buildup in mold passages. Just 1/64″ of scale can reduce the heat transfer rate up to 40%. Using an acid/water mixture, the fluid is circulated by a low pressure pump. The fluid helps dissolve the scale slowly so good heat transfer can return. This type of unit also is used to clean heat exchangers.

While the above is basic in its presentation, the message is clear; IMS understands and can help. IMS has the expertise and the equipment to help maintain and even improve your process. Good parts and reduced scrap means you make money.

That is what we are here to help with. Call IMS Today for all your Injection Molding needs.

-

Gate Cutters

How to Select the Right Gate Cutter for Your Job

April 19, 2022

De-gating a plastic part from its runner may be your final operation before shipping the parts to the customer. Often it is a challenge to remove a runner and leave the part cosmetically, functionally and structurally intact. Choosing the proper gate cutter with the necessary physical characteristics and features becomes an important decision.

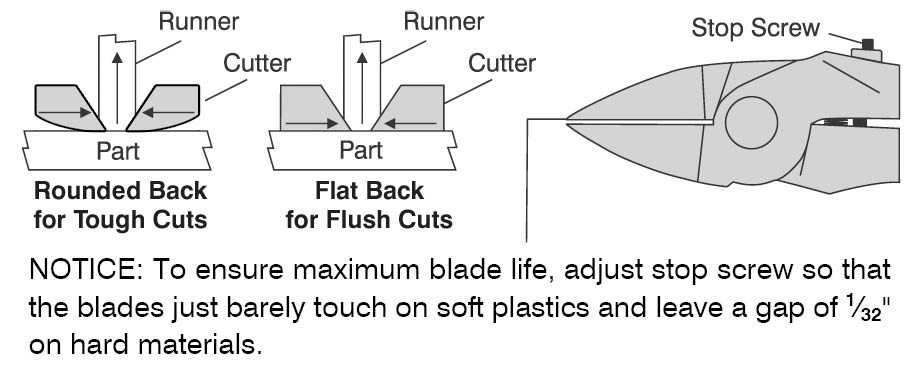

Therefore, when selecting a gate cutter, consider the length of the handle, blade length and opening, blade angle relative to the handle and the contour of the back of the blade (the blade characteristics should match the part at the area of the de-gating) and features such as a blade stop, type of spring and handles. Consider the following features:

Blade Stop

Gate cutters are actually wedges that cut from both sides until the tensile strength of the uncut section at the middle is overcome, and the remainder of the runner or sprue is “snapped” out. This rapid release causes blades to hit each other, shortening their life.

For this reason, a blade stop screw is recommended if the cutter is to be used on hard, brittle materials. The screw should be set so the blades stop short of hitting each other. For softer materials, a better cut can be obtained using a very thin, sharp blade. If a blade stop is used with softer materials (polyethylene, flexible PVC, etc.), it should be adjusted for minimal blade gap. This allows the blades to cut farther through the runner, yet only allows the blades to touch slightly.

Springs

Leaf springs are welded to the handles and covered by hand grips. Generally, they are set to a lower pressure and require less effort to squeeze, thereby reducing user fatigue. Coil springs offer a stronger return pressure “fly back” when releasing from a cut, but require more pressure to make a cut. Also, they can be easily and inexpensively replaced by the operator.

Handles

The length of the cutter’s handles determines how much pressure the operator must exert to cut through a gate or sprue. A cutter with a handle that is too short will cause excessive strain on the operator’s hand. A cutter with a handle that is too large for the operator’s hand is difficult to grip.

Try to match the cutter with the operator’s hand and the gate or sprue being cut. Ergonomic-contoured handles are effective in reducing the fatigue that can accompany the prolonged squeezing action of gate cutting. They minimize strain on the smaller, weaker fingers by keeping them from pulling from a tight-fisted position. This reduces the risk of carpal tunnel syndrome.

We have a wide range of gate cutters to fit all your gate cutting needs. If we don’t have it in stock, chances are, we can make it!

We encourage you to send us a small quantity of parts with the runners attached, so we can recommend the best cutter for your application or we can design unique cutter blade configurations to your specifications. Reduce muscle fatigue and Carpal Tunnel Syndrome with custom-made ergonomic gate cutters.

Contact the IMS Supply Team today at sales@imscompany.com or call for more details and an RA number. Then send a sketch and some samples of your molded parts with uncut gates to get a prompt quotation.

-

Barrel Insulation Blankets

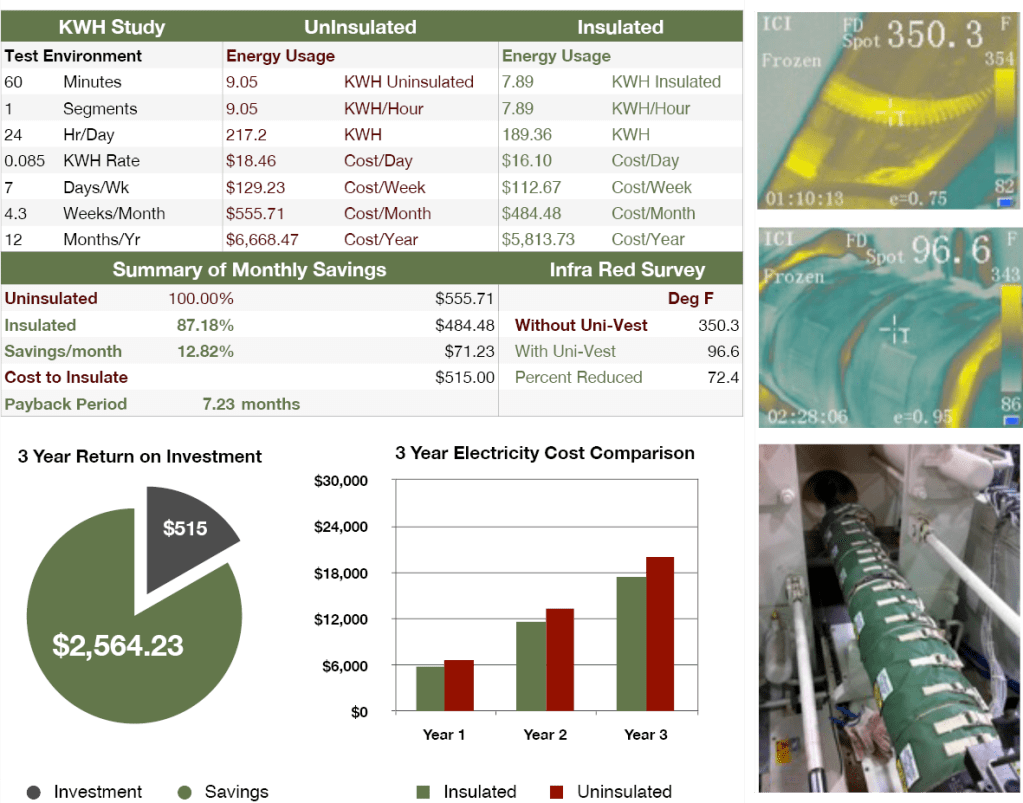

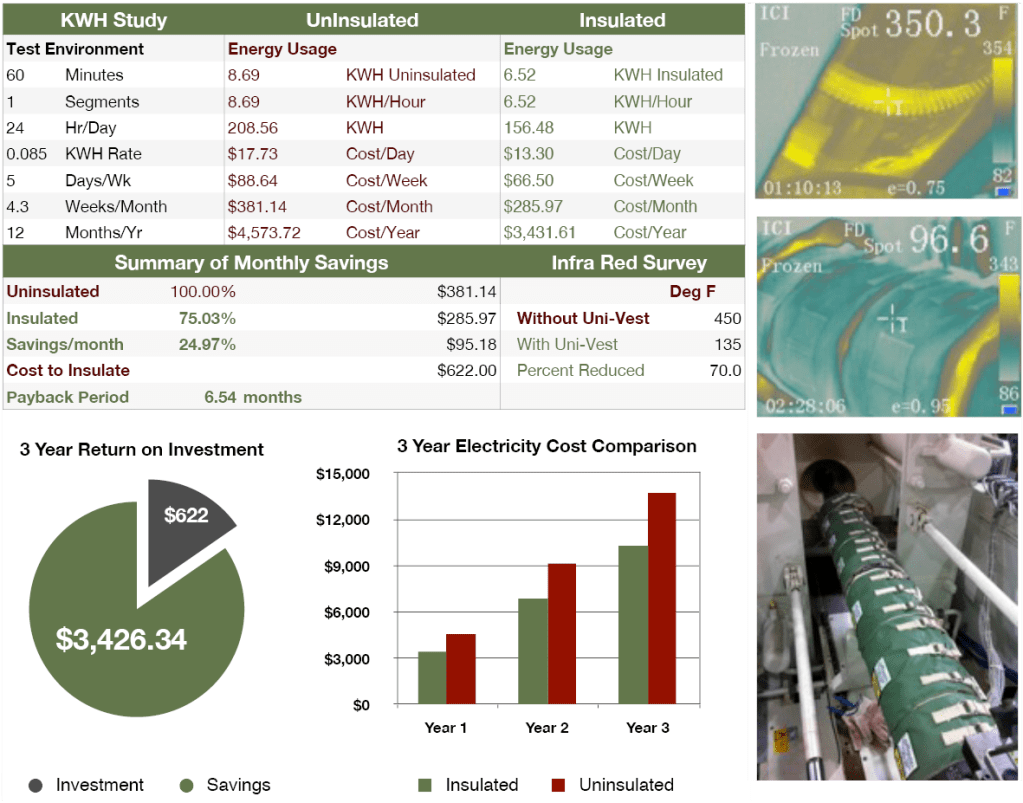

ROI Press Study

Pays for Itself In Energy Savings

April 12, 2022

150 Ton | 200 Ton | 400 Ton | 500 Ton

700 Ton | 1000 Ton | 1100 Ton | 2450 Ton

Many States offer Financial Incentives for Energy Efficiency

UNIVEST® Insulation Blanket Energy Savings Qualify!

Find out if your state offers any programs: http://www.dsireusa.org

Database of State Incentives for Renewables & Efficiency®- Minimizes barrel heat loss

- Reduces electrical use on heater bands

- Keeps energy costs down

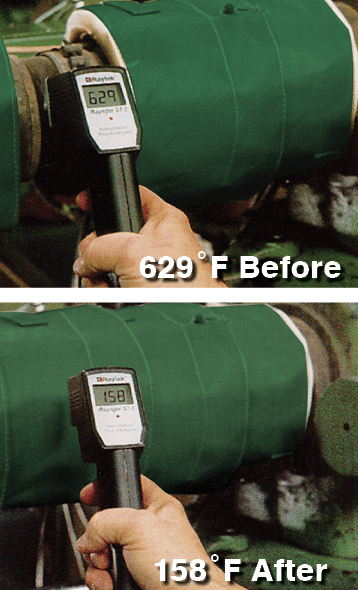

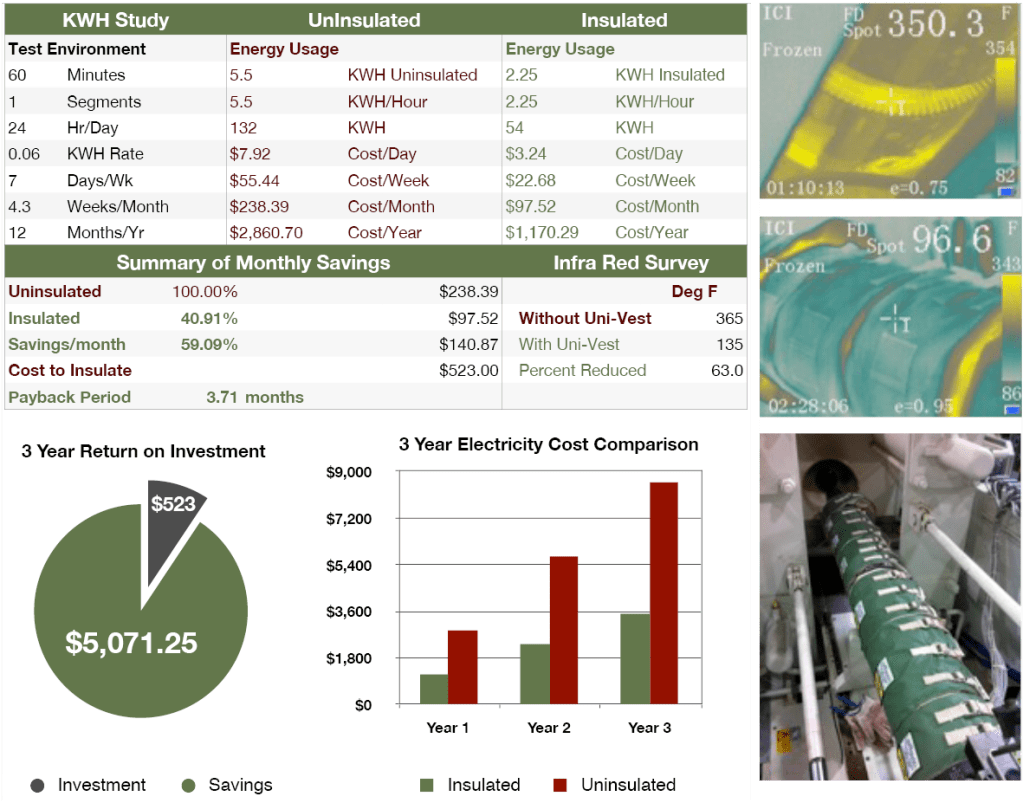

KWH Study Thermography Report

Toyo – 150 Ton

Cost to insulate: $495.00

Thermography report shows 254° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 72% (per machine) drop in radiant heat loss into climate controlled facility.

Toyo – 200 Ton

Cost to insulate: $515.00

Thermography report shows 254° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 72% (per machine) drop in radiant heat loss into climate controlled facility.

Van Dorn – 400 Ton

Cost to insulate: $523.00

Thermography report shows 230° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 63% (per machine) drop in radiant heat loss nto climate controlled facility.

Van Dorn – 500 Ton

Cost to insulate: $622.00

Thermography report shows 315° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 70% (per machine) drop in radiant heat loss into climate controlled facility.

Van Dorn – 700 Ton

Cost to insulate: $1,009.00

Thermography report shows 315° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 70% (per machine) drop in radiant heat loss nto climate controlled facility.

Van Dorn – 1000 Ton

Cost to insulate: $1,337.00

Thermography report shows 315° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 70% (per machine) drop in radiant heat loss into climate controlled facility.

Van Dorn – 1100 Ton

Cost to insulate: $1,400.00

Thermography report shows 32.1° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 34% (per machine) drop in radiant heat loss into climate controlled facility.

Van Dorn – 2450 Ton

Cost to insulate: $1,638.00

Thermography report shows 315° drop in surface temperature when UniTherm Insulation Systems are installed.*Yielding a 70% (per machine) drop in radiant heat loss into climate controlled facility.

-

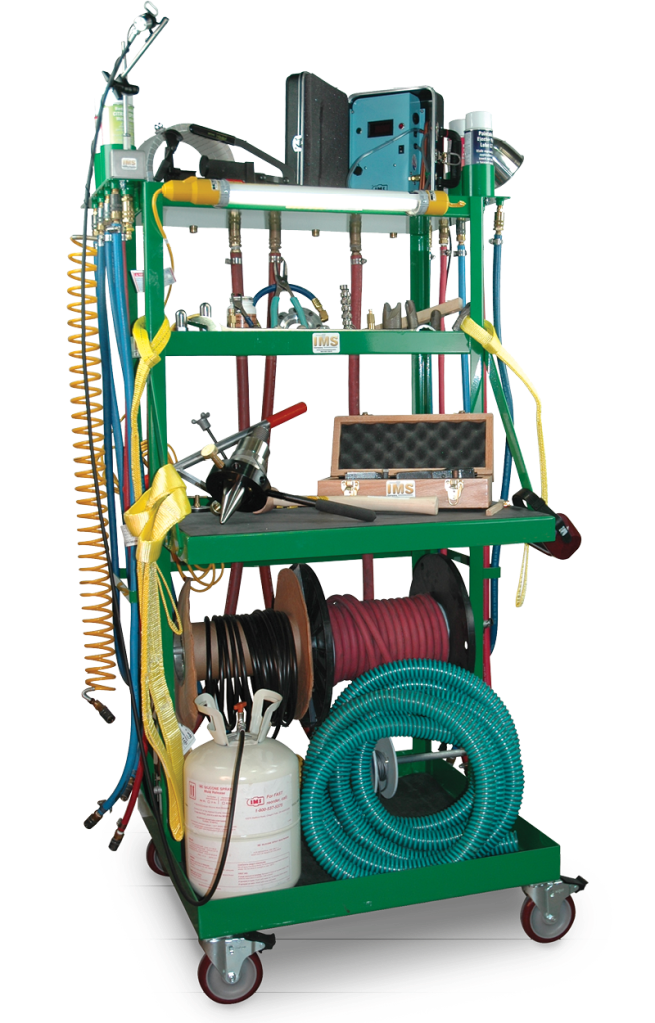

Reduce Mold Setup Time!

Faster Mold Changeover Saves Time & Money

April 4, 2022

IMS Select: The Hoist Ring Rack

It is a good idea to keep the most common rigging products you use on this cart. You may want to affix user installed labels on your cart to be sure products are returned to their proper location. Quick Mold Change

Using a video camera, record at least two mold (more preferably) changeovers made by different technicians. Have a meeting with your team, discuss and list what procedures work the best. Everyone has a trick or two up their sleeve that can be passed on.

Here are a few suggestions for discussion:

- What can be done while the mold that is coming out is still running?

- List the steps to be done as soon as the order comes for the mold change.

- List the steps to be done as soon as the machine is shut down.

- What can be taken care of before starting the changeover? (Coffee breaks, bathroom breaks, etc.)

- Who’s going to troubleshoot running machines while the changeover is in process?

Examine the list. How much set up time can be saved in preparation?

Here’s a few examples of places to shave some time off your set up:

- Have the mold being set ready at the machine before shut down

- Install FasTie Couplers on your Ejector Bars

- Install Quick Change Waterline Fittings

- Preheat the mold off line with a spare thermolator

- Pre dry your material in a Mobile Drying Hopper

- Have an IMS Mobile Set Up Cart stocked and ready to go with Eyebolts, Straps, Bolts, Water Fittings, etc.

Molding Safety Checklist

Inspect the press and surrounding areas including all auxiliary equipment for the following:

- Is the area clean and free of all potential hazards?

- Is other electrical equipment that could be hazardous during the operation locked out?

- Are the correct mold straps used to strap the mold together?

- Did you perform the daily inspection on the hoist/crane?

- Are the holes in the platen in good condition? Will they be able to hold the mold?

- Are the clamps the correct size for the mold?

- Are the clamps cracked or bent?

- How many clamps are needed to hold the mold?

- Are the clamps spaced evenly? It is essential that the clamps are placed properly.

- Make sure the bolts for the clamps are the correct size & grade.

- Make sure you are using the proper grade of bolts.

- Are the bolts in good condition?

- Check the manufacturer’s torque information to see how much torque needs to be placed on the bolts.

- Don’t rely on air pressure to torque bolts properly!

- It is NOT recommended to re-use bolts from a previous application