Molding Safety Checklist

June 9, 2022

Inspection

Inspect the press and surrounding areas including all auxiliary equipment for the following:

- Is the area clean and free of all potential hazards?

- Is other electrical equipment that could be hazardous during the operation locked out?

- Are the correct mold straps used to strap the mold together?

- Did you perform the daily inspection on the hoist/crane?

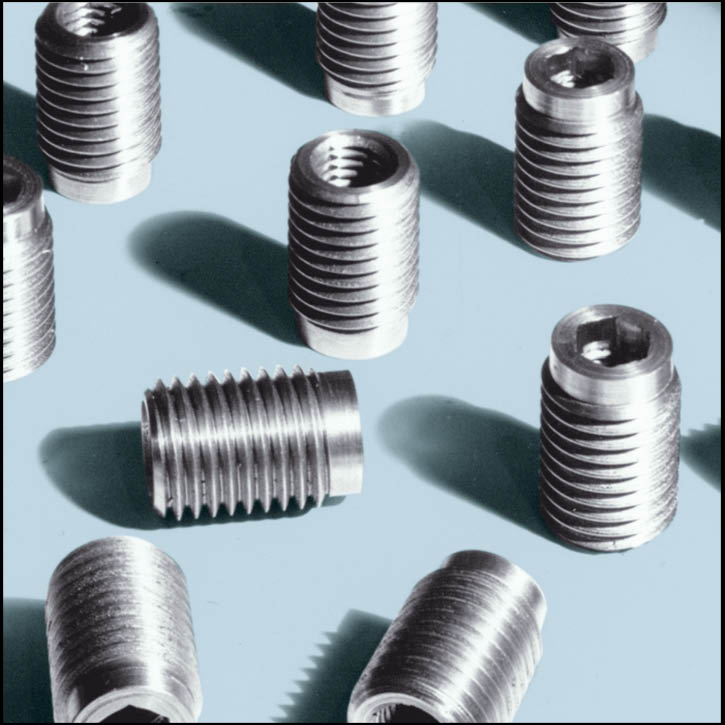

Holes in Platens

Mold Clamps

- Are the clamps the correct size for the mold?

- Are the clamps cracked or bent?

- How many clamps are needed to hold the mold?

- Are the clamps spaced evenly? It is essential that the clamps are placed properly.

Clamp Installation

- Make sure the bolts for the clamps are the correct size and grade.

- Make sure you are using the proper grade of bolts.

- Are the bolts in good condition?

- Check the manufacturer’s torque information to see how much torque needs to be placed on the bolts.

- Don’t rely on air pressure to torque bolts properly!

Closed-Toe Mold Clamps

For basic applications use mold clamps that have a slot to accept the bolt. They never fall off the bolt.

Open-Toe Mold Clamps

Take great care when handling open-ended clamps. They may slip and fall to the floor or down the chute when the tech is trying to bolt it in.

Leave a comment