June 15, 2022

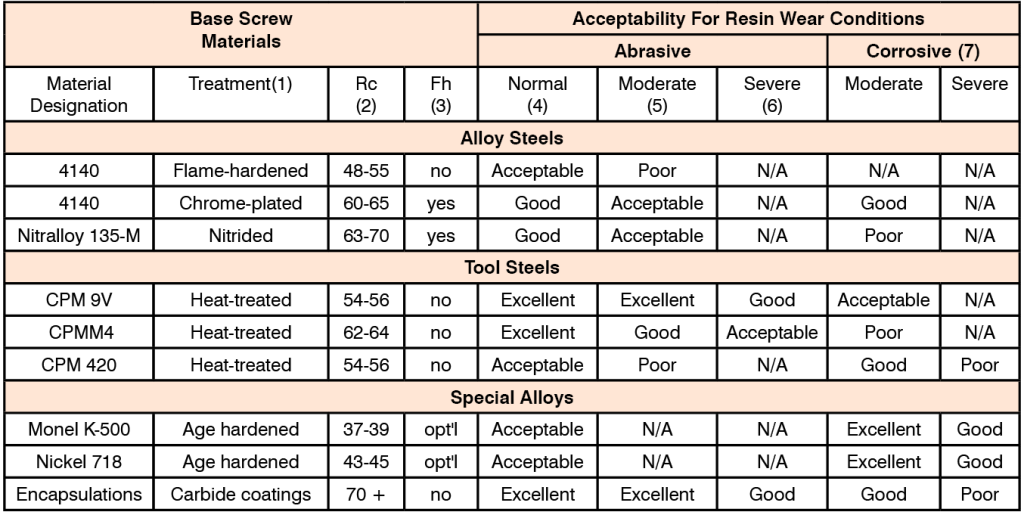

(1) Includes chrome-plating to .003”-.005” and gas or ion nitriding for 24+ hour cycle.

(2) Rockwell C hardness.

(3) Flight hardsurfacing required.

(4) Thermoplastics with no reinforcements.

(5) Thermoplastics with up to 30% reinforcement.

(6) Thermoplastics with more than 30% reinforcement.

(7) Moderate includes cellulosics, acetals and others containing corrosive additives.

Material Options

Feed screws are manufactured from conventional tool steels such as 4140, D-2 or H-13. Particle Metallurgy processing such as CPM9V, S90V, CPMM4 is also used.

Nitralloy 135M

Excellent low-cost, prehardened steel machined and Nitrided for 72 hours. For wear-resistant or general purpose materials. Low-cost alternative when excessive wear is not a primary consideration.

D-2 Tool Steel

A high carbon/high chrome (12%) tool steel with good wear resistance, but low on torque strength.

H-13 Tool Steel

A good high strength pre-hardened tool steel which is machined, thru-hardened, and ground dimensionally, then nitride hardened for 72 hours for better wear resistance. H-13 is tough and can handle pressure and torque.

CPM9V Tool Steel

Highly wear resistant tool steel with a high percentage of vanadium carbide developed for high wear (abrasive) applications. It resists wear from abrasive fillers in resin.

CPM10V Tool Steel

Excellent wear-resistant tool steel. Contains 10% vanadium. Ideal for highly abrasive plastics.

CPM420V Tool Steel

Stainless tool steel best suited for corrosion resistant applications.

CPMM4 Tool Steel

Crucible’s CPM®-M4 is a high vanadium, special purpose, high speed steel exhibiting better wear resistance and toughness than D2 or CPM®-9V. CPM®-M4 has a hardness rating of 64.0.

M-4

M4 has higher resistance to heat than 9V The heat tolerance for CPM 9V is only 800 and the heat tolerance for M4 is 1200˚F

Hard Facing On Screw Flights

4140

A tool steel with good strength when surface treated or hard faced.

STELLITE #6

4140 based. Recommended for resins with a low percentage of filled materials. 37-42 RC hardness.

STELLITE #12

Save as above with 40-47 RC hardness.

COLMONOY 56

Nickel based. More wear resistant than Stellite. Recommended for glass-filled or resins. 50 to 55 RC hardness. More wear resistant than Stellite Recommended for glass-filled resins. 50-55RC.

Nitriding

Increases the hardness and life of tool steel screws such as 135M and 4140. Very cost effective.

A 4140 alloy steel screw can be nitrided satisfactorily, however, a nitriding steel (such as Nitralloy 135M) has aluminum added to give a better response in nitriding hardness, both as to consistency and depth.

Gas Nitriding is used to create a surface hardness on the screw. The hard layer of steel will vary in depth from .007” to .015” depending upon the length of the nitriding cycle. The hard layer (usually well above 60 RC) is achieved by heating the steel in an atmosphere of nitrogen (ammonia gas) at temperatures of 950 to 1050˚F. The nitrogen atoms are diffused into the surface of the steel, combining with nitride-forming elements, such as chromium, aluminum, molybdenum, vanadium, tungsten and titanium, to produce a very hard surface, particularly for the first .002” to .005” depth. Nitrided screws have a very good wear resistance until the surface hardness is worn away. After the surface is worn .007”, wear accelerates and the screw may quickly be worn to a condition that is beyond repair.

Chrome Plating

Offers hardness and low friction with corrosion protection. Double and triple chrome plating often used for corrosive applications.

Although most processors are familiar with chrome-plating, there is an important specification to be considered in purchasing a chrome-plated screw or having a repaired screw chrome-plated. The critical specification is the depth of the plating.

Most of the screws that are not manufactured from solid tool steels or special alloys have a flight hard-surfacing material welded to form the outside diameter of the screw flights.

The hard-surfacing materials are predominantly cobalt-based or nickel-based. The most common cobalt-based materials include the Stellites (6 and 12) which exhibit uniform wear and are satisfactory in non-corrosive environments.

Carbide Coating

Carbide coating – Guaranteed to double the life of a CPM9V screw.

Particle Metallurgy Tool Steels

Examples of tool steels made by the PM process that are used for screws include CPM9V, CPMM4, and CPMS90V, all from Crucible

Materials Corporation. However, there are other manufacturers of PM steels that offer comparable characteristics to the CPM products.

Nickel Alloys

Processing fluoropolymers must be done with nickel alloy screws or screws that are totally encapsulated with a relatively iron-free material. Monel K-500 and Inconel 718 are both nickel alloys that can be hardened into the low 40’s RC. Both resist corrosion quite well and, although very expensive, provide an acceptable solution to the extreme corrosiveness of PVC.

Total Encapsulation

There are several methods used to totally encapsulate a screw with wear and/or corrosion resistant material. The methods include

detonation guns, HVOF systems and various spray weld processes. A wide selection of materials can be used ranging from the types

of materials used for flight hard-surfacing to customized products containing very hard wear resistant carbides.

NOTE: Screw and Barrel wear over time, will reduce screw recovery, increase scrap rates and increase energy consumption. While molders may recognize the costs of wear, they usually accept it as a necessary part of their business. Using a nozzle tip blank such as IMS’s 136499 or 136486, try to inject slowly forward at reduced pressure to quantify the ability of the press to hold cushion. You can quickly spot a problem before it becomes serious.

Leave a comment