Single Station Hopper Loader Systems

August 4, 2022

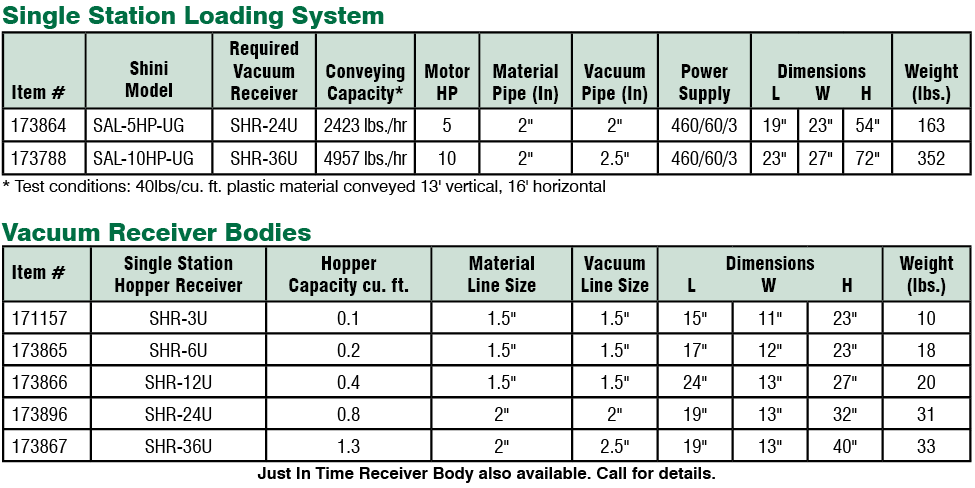

Heavy Duty Blowers with Separate Single Receiver Body

Features

• Floor Level Blower & Controller

• Separate Stainless Steel Receiver

• Microprocessor Controller

• Audible Material Shortage Alarm

• RS485 Communication Interface

• On board controller compatible with Shini SPV-U Proportional Valve (see page 657)

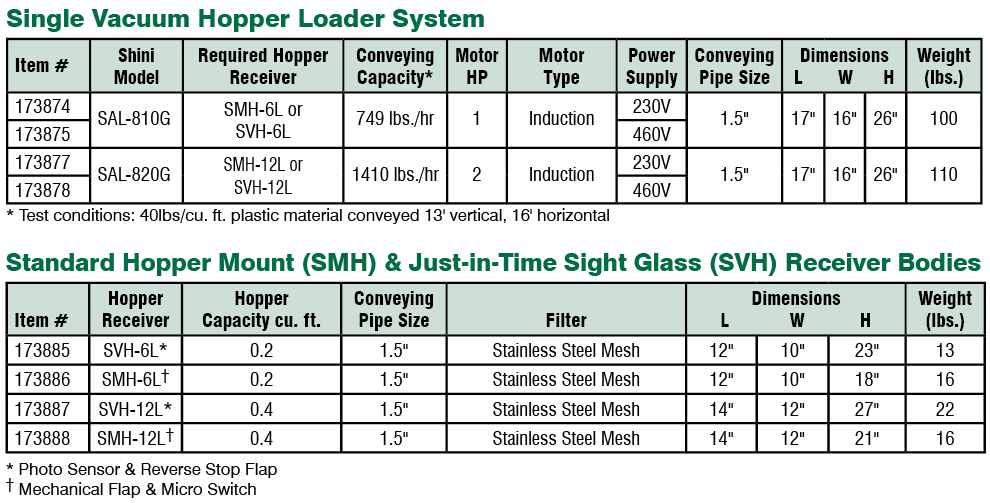

Single Vacuum Hopper Loader Systems

Floor Level Blowers with Separate Receiver Body

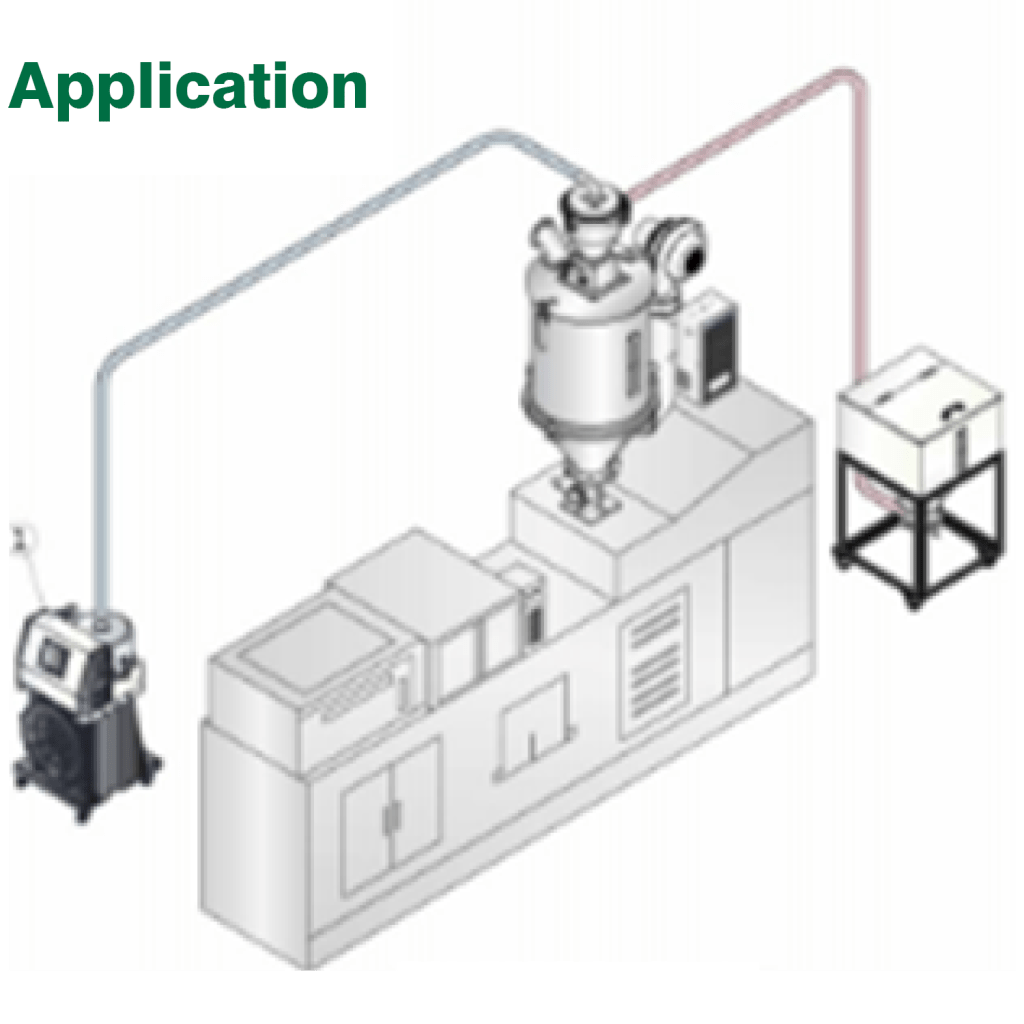

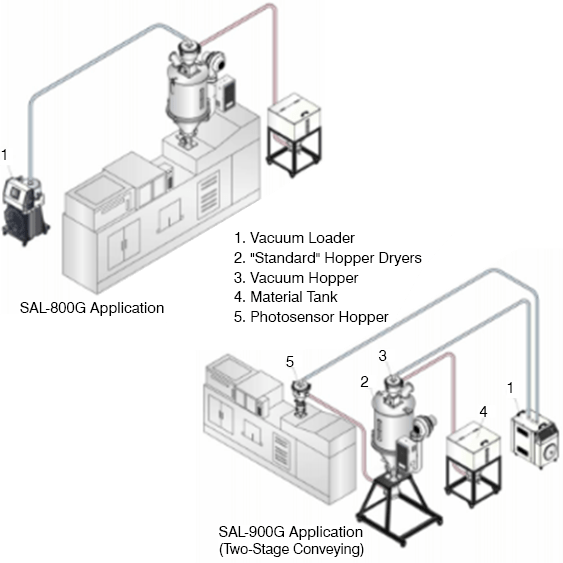

Shini USA SAL-G Single Vacuum Hopper Loader Systems are designed to convey material over long distances with a combination floor-level vacuum system & separate receiver body. The receiver body is mounted to the machine/hopper while the main unit’s vacuum motor and controls are located on the blower for easy control and maintenance. Each unit comes with microprocessor controls, digital display, air filter, and low material alarm.

Features

• Floor Level Blower & Controller

• Heavy Duty Casters

• Microprocessor Controller

• Audible Material Shortage Alarm

• RS485 Communication Interface

Multi Station Hopper Loader Systems

Heavy Duty Blowers and Multi-Station Receiver Bodies

Shini SAL-UG-122/124 Multi-Station Loader Systems are designed to convey material to two or four separate stations with a combination floor-level vacuum system & separate receiver bodies. The receiver bodies are mounted to multiple machines/hoppers while the main unit’s vacuum motor and controls are located on the blower for easy control and maintenance. Each unit comes with microprocessor controls, digital display, air filter, and low material alarm.

Features

• Floor Level Blower & Controller

• 2 or 4 Hopper Loading System

• Separate Stainless Steel Receiver

• Microprocessor Controller

• Audible Material Shortage Alarm

• RS485 Communication Interface

• 460 Volt/60/3 Phase

Leave a comment