November 2, 2022

When setting up a new or existing mold, there are multiple variables the processor must handle. First on the list is setting up the barrel zone temperatures. This allows operators to spend less time waiting for the machine to warm up so that they can prepare for production.

Nevertheless, the question remains of what temperature we want the melt to be, and what should the temperature profile of the barrel zones be. If you were to ask a panel of molding professionals, you’d find the common denominator in making quality parts is setting the correct melt temperature. Incorrect temperature settings can cause a multitude of problems such as resin waste and poor part performance.

Ideally, a molder should always consult with their resin supplier. The supplier will give them temperature recommendations for both drying time and molding, and in some cases, even how to set the heat profile.

However, the discussion isn’t that simple and doesn’t end there.

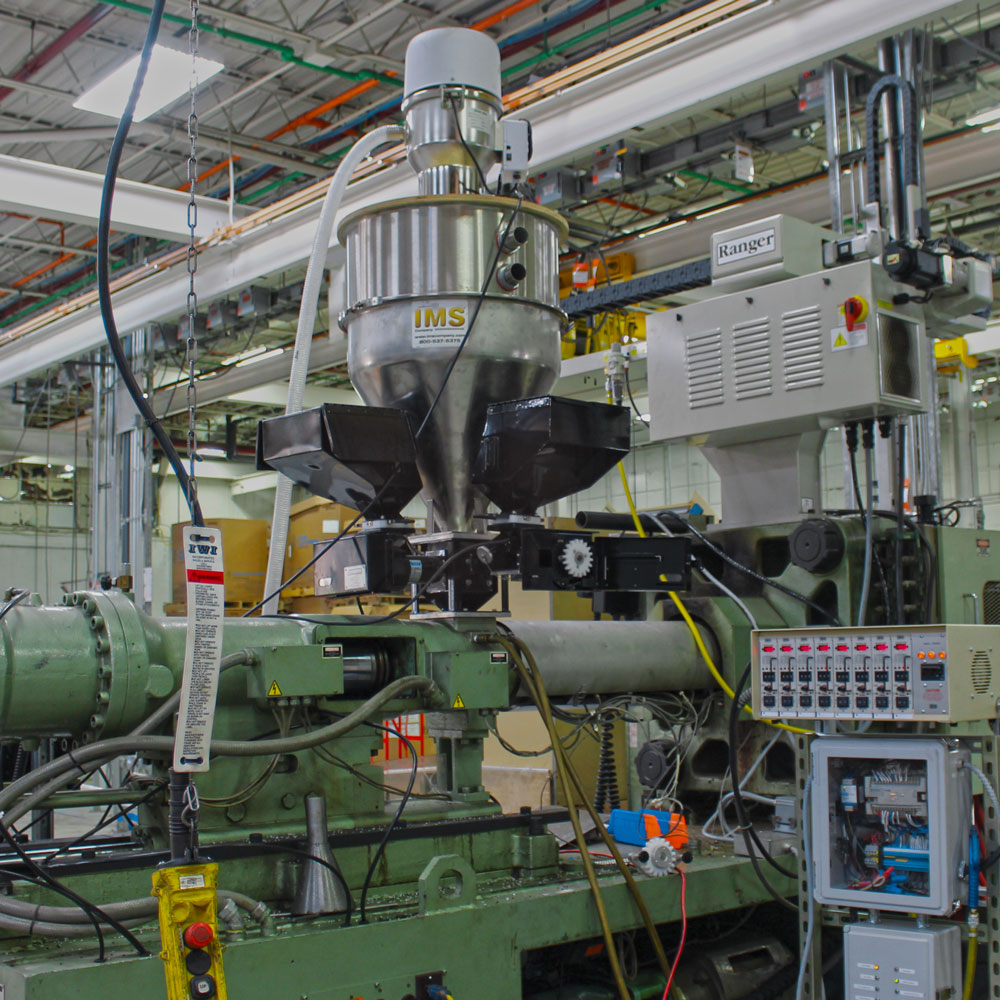

Most injection molding machines have up to 5 individual heating zones. To begin, the processor picks a target melt temperature. No matter your experience, it’s best practices to check with the manufacturer’s recommendations. An excellent place to look for this information is on material specification sheets where you will find the suggested temperature range. A rule of thumb is to select something near the center of that range. This gives you the flexibility to adjust the material temperature up or down and still be within range. From here, you will begin to set the barrel zone profile.

Most barrel heating zones are set with a gradually increasing temperature profile from the rear zone to the metering (front) zone. There are a few exceptions to this, such as if you’re molding crystalline or polycarbonate materials. This is because the properties of these materials can be hard to heat to their processing temperature.

When the rear zone is too low, it can cause air to be trapped in the plastic, resulting in air bubbles in the mold sockets.

If the rear zone temperature is too high, it can cause the plastic to melt in the feed throat. This results in blocking the flow of granules into the barrel. It’s a waste of energy, as most of the heat produced is taken away by cooling water produced from the hopper feed.

If you’re looking to adjust the melt temperatures, you will do so in the middle zone. When heat is added to this zone, any temperature deviations are eradicated due to the heat being rigorously mixed through screw rotation before any plastic can amass ahead of the screw.

This is sometimes referred to as a “pyramid” profile. This is where the heat ramps up to its highest point in the center zone, then gradually drop down towards the front zones.

An additional step that can be taken is to wrap your barrel in insulation blankets. This helps with maintaining consistent heat by keeping the heat in the barrel. Heater bands minimize barrel heat loss, reduce electrical use, and help keep energy costs down. Click to read our Barrel Blanket ROI Study.

What have we learned? The optimal way to set barrel temperatures is to closely maintain them. Make sure to slowly increase the melt temperature as the plastic flows through the screw flights. As it approaches the front zone, just ahead of the screw, avoid adding or removing heat because, in the front zone, the screw cannot mix any unevenly heated plastic.

At IMS, we stand by our customers and work with you to maintain and improve your processes. We believe in saving you time and money while reducing scrap and supplying quality parts. Let us show you why we’ve been the trusted source of supplies, components, auxiliary machinery, and equipment for over 70 years.

Leave a comment