Instructions for Use

3/1/2024

Grooving & Installation Instructions

(See drawing for proper groove depth)

- Machine your sliding ring or tip body in lathe, or grind (if above 48 Rockwell C).

- Be sure to protect all polished surfaces and threads.

- Recommended lathe speed: 80 surface feet per minute.

- Use groove cutting tool.

- If groove is cut into a case-hardened surface, screw tip or check ring should be heat treated through to 46-48 Rockwell C prior to installation of BRODY-ring®.

- If groove is cut into a nitrided surface, screw tip or check ring should be renitrided prior to installation of BRODY-ring®.

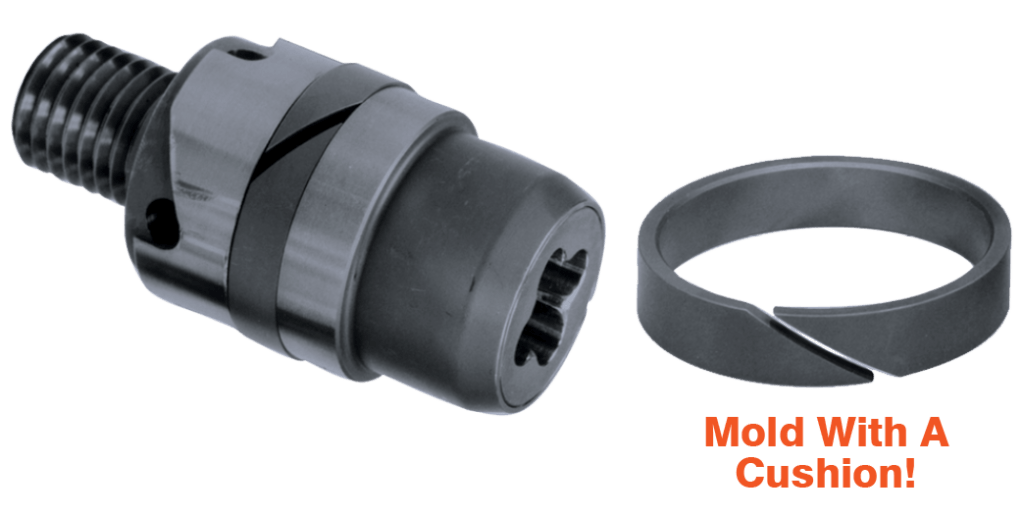

- Slowly and carefully slide BRODY-ring® over tip body or sliding ring until it snaps into groove.

- To install in barrel, use hose clamp or piston ring compressor to compress BRODY-ring®.

Special Notes

- BRODY-rings® take up a temporary maximum of .025” total wear between screw tip and barrel.

- BRODY-rings® are only a temporary solution to worn barrel problems and should only be used until complete barrel resleeving (also available from IMS) is possible.

- If any questions, please call an IMS Customer Service

Representative. - Wall thickness under groove must be equal to groove depth for adequate check ring strength.

Leave a comment