Separation of metal contaminants is essential in plastics processing. Tramp Metal in the production line is not only a risk to the consumer, but also to equipment. Metal separation in plastics processing offers several benefits, contributing to the efficiency, quality, and safety of the overall plastic manufacturing process. Here are some key advantages:

1/29/2024

- Final Product Quality and Compliance – Many industries, such as food packaging, automotive and medical, are subject to regulations and standards regarding the quality, purity, and safety of their products. Metal separation ensures that the final products meet those standards.

- Consistent Processing – The presence of metal can lead to inconsistent melting and molding, affecting overall process stability. Removing metal ensures a more uniform and consistent processing of plastic materials.

- Cost Savings & Environmental Impact – Metal separation lowers the risk of damage to equipment, improves process efficiency, and reduces the risk of rejected product, reducing the amount of waste generated.

- Process Optimization & Enhanced Safety – Metal separation ensures that the process operates at its highest efficiency, with minimal disruptions. It also enhances workplace safety by reducing the risk of accidents or malfunctions caused by metal particles in the equipment.

- Customer Satisfaction – Consistently delivering high-quality, contaminant-free products improves customer satisfaction and builds trust in the brand. This can lead to increased customer loyalty and a positive reputation in the market.

HOW METAL DETECTORS WORK

The product passes through an opening in the detector, which houses a unique three-coil search head. This is comprised of windings around an aperture opening. The transmitter is in the center of this coil with two receivers surrounding it, one placed at the entrance head and one at the exit. When a piece of metal passes through the coil opening, a signal is generated, calculated and activates further operations or devices. Some metal detectors are equipped with automatic reject mechanisms, which isolate contaminated material and remove it from the product flow. Within the aperture opening, an electromagnetic field is created.

It’s important to note that the specific design and technology of metal detectors can vary among manufacturers, but the underlying principles are generally based on electromagnetic induction or eddy currents. Here’s a brief explanation of how they work:

Metal detectors consist of a coil through which an alternating current flows. When a metal object passes through the detector, it disrupts the electromagnetic field generated by the coil. This disruption induces eddy currents in the metal object, creating a secondary magnetic field. The detector senses the change and triggers an alarm to alert operators about the presence of metal.

An alternating magnetic field is generated by a coil in the detector. When a conductive metal object passes through this field, it induces eddy currents in the metal. The eddy currents, in turn, create their own magnetic field that opposes the original magnetic field. The detector reacts to this change and signals the presence of metal.

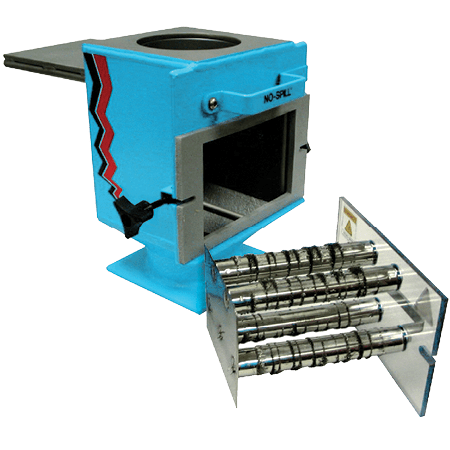

Drawer Magnets

The drawer magnet is installed in the processing line, usually to a hopper or chute through which the plastic material flows. The magnetic drawer is positioned to attract and capture any ferrous particles present in the material. Periodically, the drawer magnet needs to be cleaned to remove the accumulated contaminants. This is typically done by removing the drawer from its housing and wiping or scraping off the captured ferrous particles.

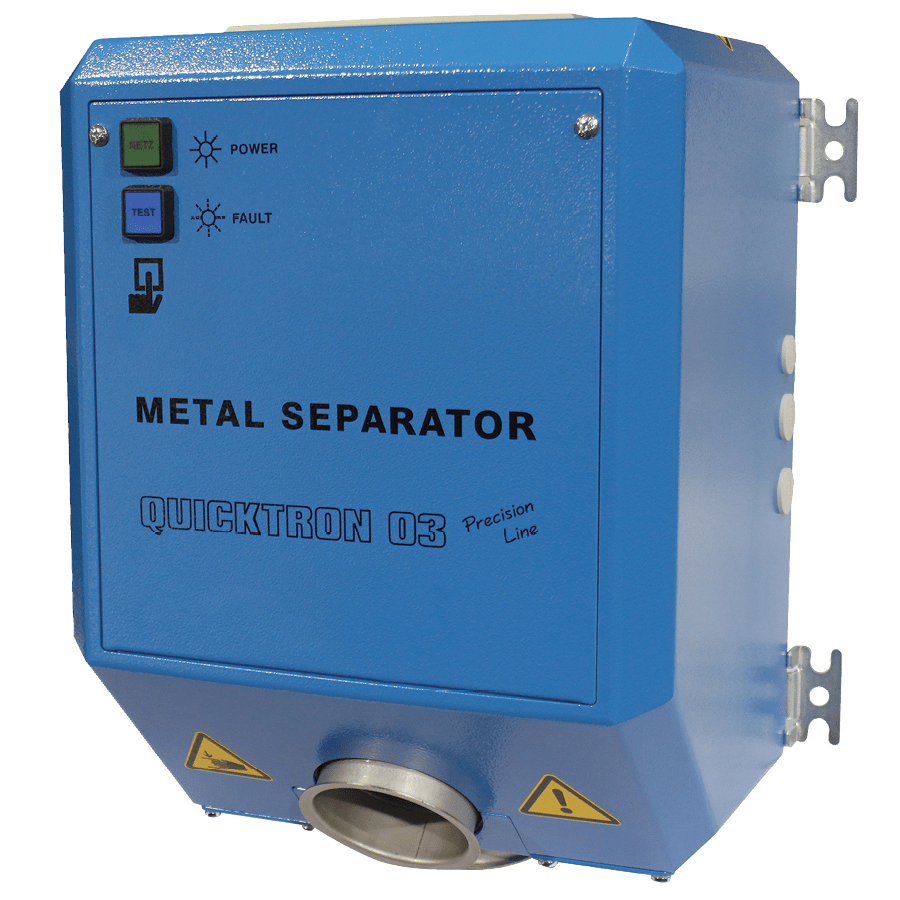

Pre-Production All-Metal Detectors

Gravity free-fall metal detectors are commonly used in industries such as food processing and packaging to ensure that metal contaminants are detected and removed from the product stream. They are designed to detect metal particles in free-falling bulk materials, such as plastic granules, as they pass through the detection zone. The high-speed reject mechanism is responsible for removing any contaminated material from the production line with minimal good material diversion.

Machine Mounted All-Metal Detectors

Provides efficient detection and rejection of both ferrous and nonferrous metal within all materials, without process interruptions. Designed especially for choke-feed applications it can bolt directly to the infeed of processing equipment and support the weight of hoppers on an injection molding machine or extruder. Fast, precisely timed pneumatic rejection mechanism results in accurate cycling and conservation of good material. Available in a high-temperature version suitable for handling product at higher-than-normal temperatures (up to 350°F.)

When considering a metal detector for plastic processing, it’s essential to choose one that meets the specific requirements of your application, including sensitivity to detect the desired metal contaminants and a reject mechanism suitable for handling plastic materials.

Leave a comment