2/5/2024

In injection molding, the nozzle tip is a critical component in the process. It plays a key role in controlling the flow of molten plastic into the mold cavity to create the desired product. Here are some important features:

- Material Compatibility – typically made from materials that can withstand the high temperatures and pressures involved in the injection molding process. Common materials include hardened steel, tool steel, or other alloys.

- Design and Shape – affects the flow and distribution of molten plastic. May have a tapered or conical shape to facilitate smooth material flow.

- Size and Diameter – should be chosen based on the specific requirements of the molding process, including the type of material being used and the design of the mold.

- Temperature Control – some come with built-in temperature control to help maintain the optimal temperature preventing premature solidification and ensuring proper flow.

- Wear Resistance – subject to wear due to the abrasive nature of molten plastics. Wear-resistant coatings or materials may be applied to extend the life of the nozzle tip.

- Shut-off Mechanism – prevent drooling or dripping of molten plastic after the injection cycle. This is particularly important for maintaining the quality of the molded parts.

- Cleanability – essential for efficient operation and maintenance of the machine.

- Compatibility – must be compatible with the specific type of material being used. Different materials may require different designs to ensure optimal performance.

- Quick Change Systems – Some injection molding systems incorporate quick-change systems for nozzle tips. This facilitates easier maintenance, cleaning, and replacement.

- Alignment with Mold Design – should align with the mold design to ensure proper filling and packing of the mold cavity.

IMS precision made Nozzle Tips are designed from high quality, heat-treated tool steel and are perfect for everyday use in the molding shop. The technicians at IMS have worked hard to bring you quality at an affordable price.

At IMS, we put our customers’ satisfaction as the highest priority. When it comes to our nozzle tips, we think you will agree that they are a great value.

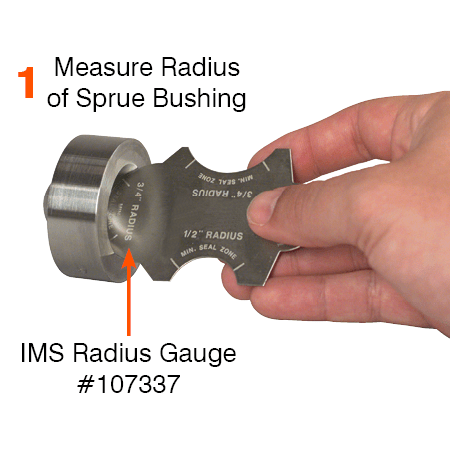

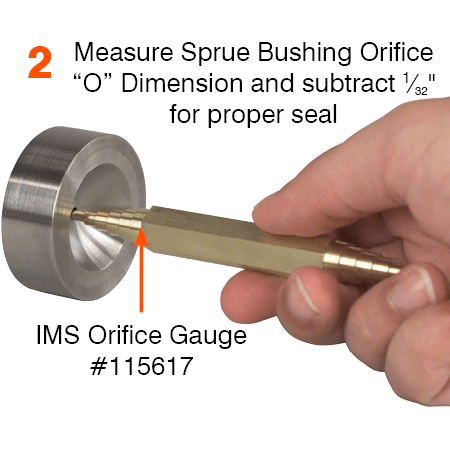

Before Ordering, Please Gather the Following Dimensions:

If your application requires higher wear resistance, sizes not listed, etc. please contact an IMS technician for a prompt quote, see the “Request for Quotation Form”

Beryllium Copper: Nozzle tips made of heat treated beryllium copper ensure maximum heat transfer plus strength and toughness. Beryllium Copper nozzle tips will help prevent tip freeze-ups, will let you lower nozzle temperature, and will enable electrical use reduction while shortening cycle times. NOTE: Beryllium Copper Nozzle Tips are not recommended for use with abrasive materials.

Here are 10 reasons to buy IMS nozzles:

- 1. Guaranteed to meet our certified material and hardness requirements.

- 2. Machined using state-of-the-art machines by experienced technicians who use the most up-to-date practices; be assured they are made with care and quality.

- 3. Finished to perfection using hand polishing.

- 4. Protected from rust and corrosion.

- 5. Protected from thread damage and nicks.

- 6. Stamped with sizes and styles for easy re-ordering.

- 7. Tested using the latest computerized measuring and checking equipment.

- 8. Quality inspected in our facility using the strictest approval practices.

- 9. Your satisfaction is guaranteed!

It’s important to follow the manufacturer’s guidelines and recommendations for the specific machine and material being used to ensure the nozzle tip functions effectively and efficiently. Regular maintenance and inspection of the nozzle tip are also crucial for optimal performance and longevity of the injection molding equipment.

Leave a comment