Postpone Barrel Repairs – Improve Press Performance

June 15, 2022

- Shorter screw travel for faster cycles

- End all O.D. blow-back

- Positive injection pressure

- Consistent shot control

- Color changes made quicker

- Retrofit MOST tips

- Give new press performance on any injection machine — even with a worn barrel

Extend Barrel Life 2 to 3X!

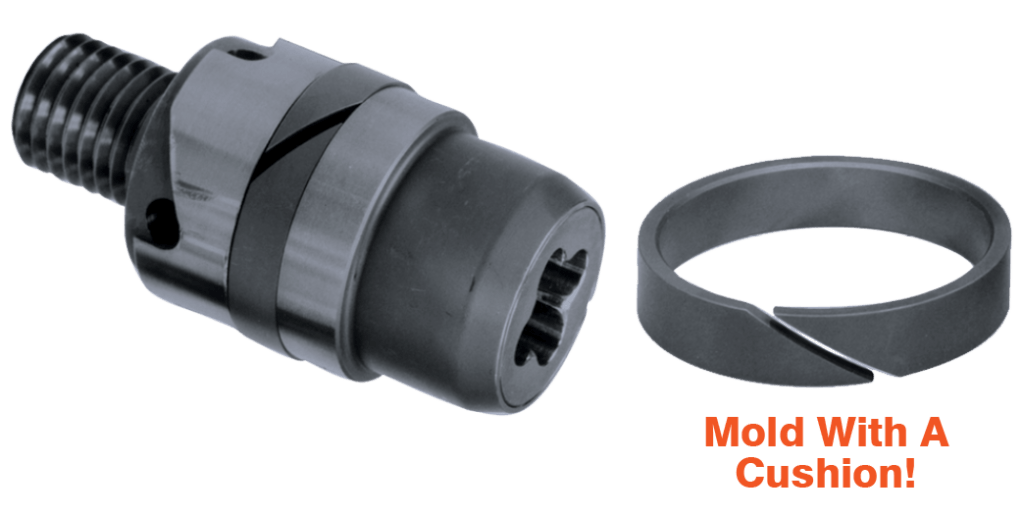

Stop Screw Tip Blow-By With A BRODY-Ring!

The introduction of the BRODY-ring was a major breakthrough in improving Reciprocating-Screw Press efficiency. Try a tip with a BRODY-ring. It will make your old press perform better than new. If your barrel is worn, the results are even more positive because you can postpone a barrel relining job until your job is completed and you can afford the downtime.

The IMS BRODY-ring molds with a cushion, allowing you to mold better parts. This ensures perfect fills every time. It maximizes part strength and lets you hold critical part dimensions more closely because you exert the same pressure on every shot. Helps minimize part strains.

The BRODY-ring prevents blow-by around the sliding ring or ball check tip. It speeds color changes because there is no space between the ring and the tip where material can hang up, burn and contaminate.

Positive shut-off of the BRODY-ring stops the jetting back of plastic around the O.D. of the sliding ring or tip body. This reduces frictional heat created by the plastic as it leaks back around the tip while you are trying to fill the part.

BRODY-rings can allow you to cut cycle time too. You do not have to OVER-STROKE (or over-retract) your screw to compensate for all the plastic that leaks back past ordinary tips of whatever design. By allowing you to shorten your screw stroke, you save cycle time. So mold with a cushion and make better parts faster!

Leave a reply to IMS BRODY-Ring® – IMS Company Blog Cancel reply