5/30/2023

Inflation is defined as the rate of increase in prices over a given period of time. It is typically a broad measure, such as the overall increase in prices or the increase in the cost of living in a country. For the past two years, the US has experienced an inflation rate higher than the long term average of 3.28%. This has lead businesses to experience higher costs, especially higher energy costs.

In a previous blog (Barrel Insulation Blankets), IMS discussed the benefits of wrapping your barrels in insulation vests. It has been well documented that insulating your injection or extrusion barrels keeps the heat applied with heater bands or cast heaters can remain in the barrel. By reducing heat loss, energy costs are reduced.

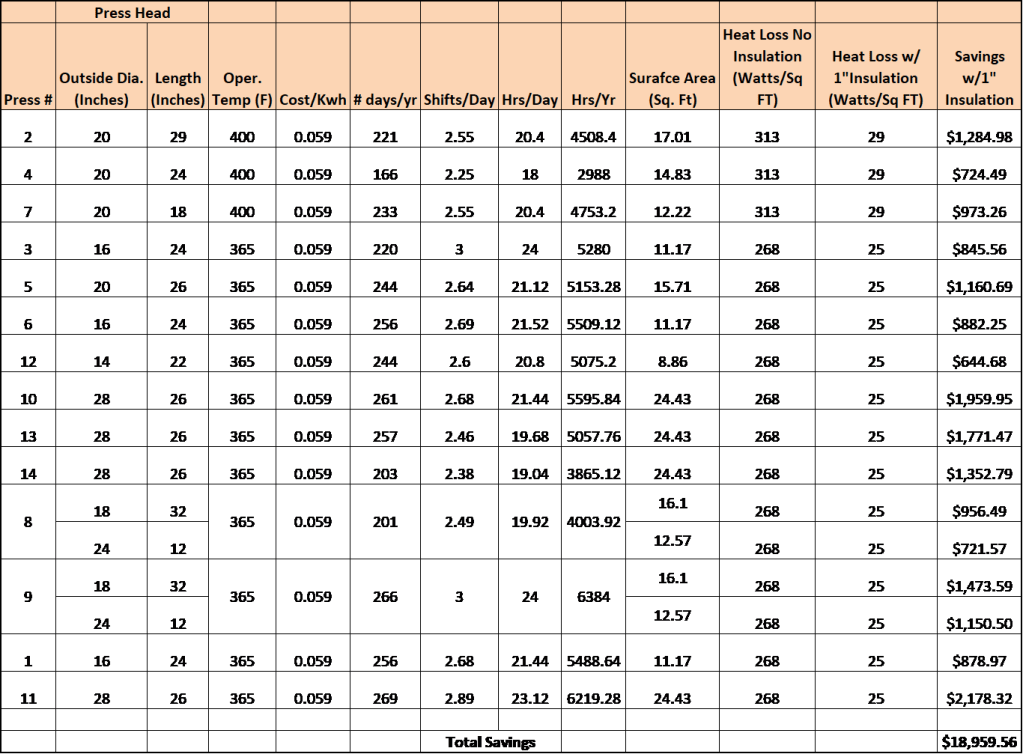

I personally conducted an analysis of savings for a customer after a visit to their facility to assess the situation. The results are chronicled below:

The chart demonstrates that taking into account current electrical rates, combined with kilowatt hour usage, the customer was in line for substantial savings.

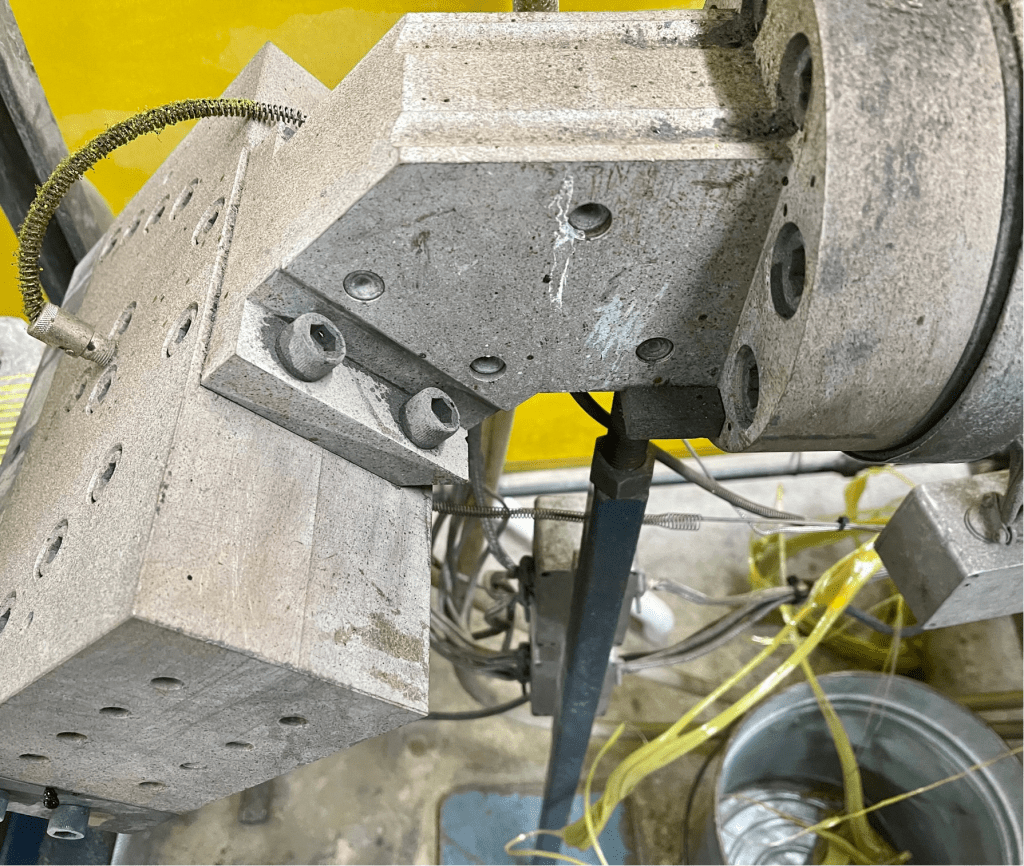

The energy saving possibilities do not end there. Extruders can wrap their dies in insulation blankets, or depending on the die configuration, white insulation board. The insulation board is rigid in nature and can be cut to fit any type of die (example below).

the die heat and makes the extrusion process more efficient.

This insulation board can also be mounted to the surfaces of injection molds to control mold sweating and retain heat.

Finally, IMS can supply insulation for items such as gate valves, large tee connections, and any other large plumbing connection.

This is where the expertise IMS offers can help molders and extruders achieve desperately needed cost savings. We offer both the products and the expertise to analyze and recommend the right solutions.

Leave a reply to Grant Roesner Cancel reply